Method for preparing micron frame-shaped manganese series lithium ion battery cathode material

A frame-shaped manganese-based lithium and cathode electrode technology, applied in the direction of manganate/permanganate, etc., can solve the problems of large product particle size, different reduction degree, difficult to control the shape, etc., to reduce polarization, Effect of improving compatibility, reducing self-discharge and short-circuit phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

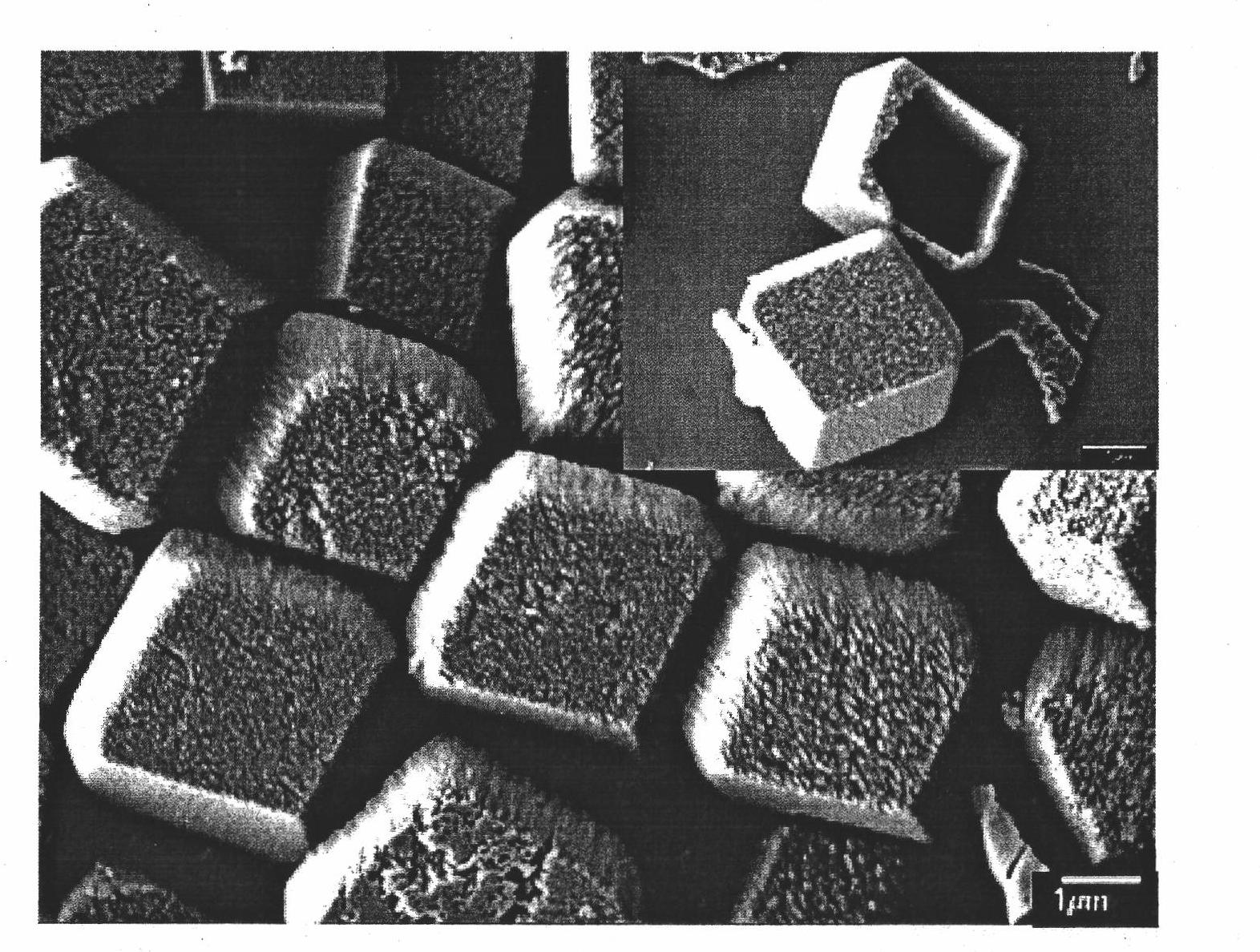

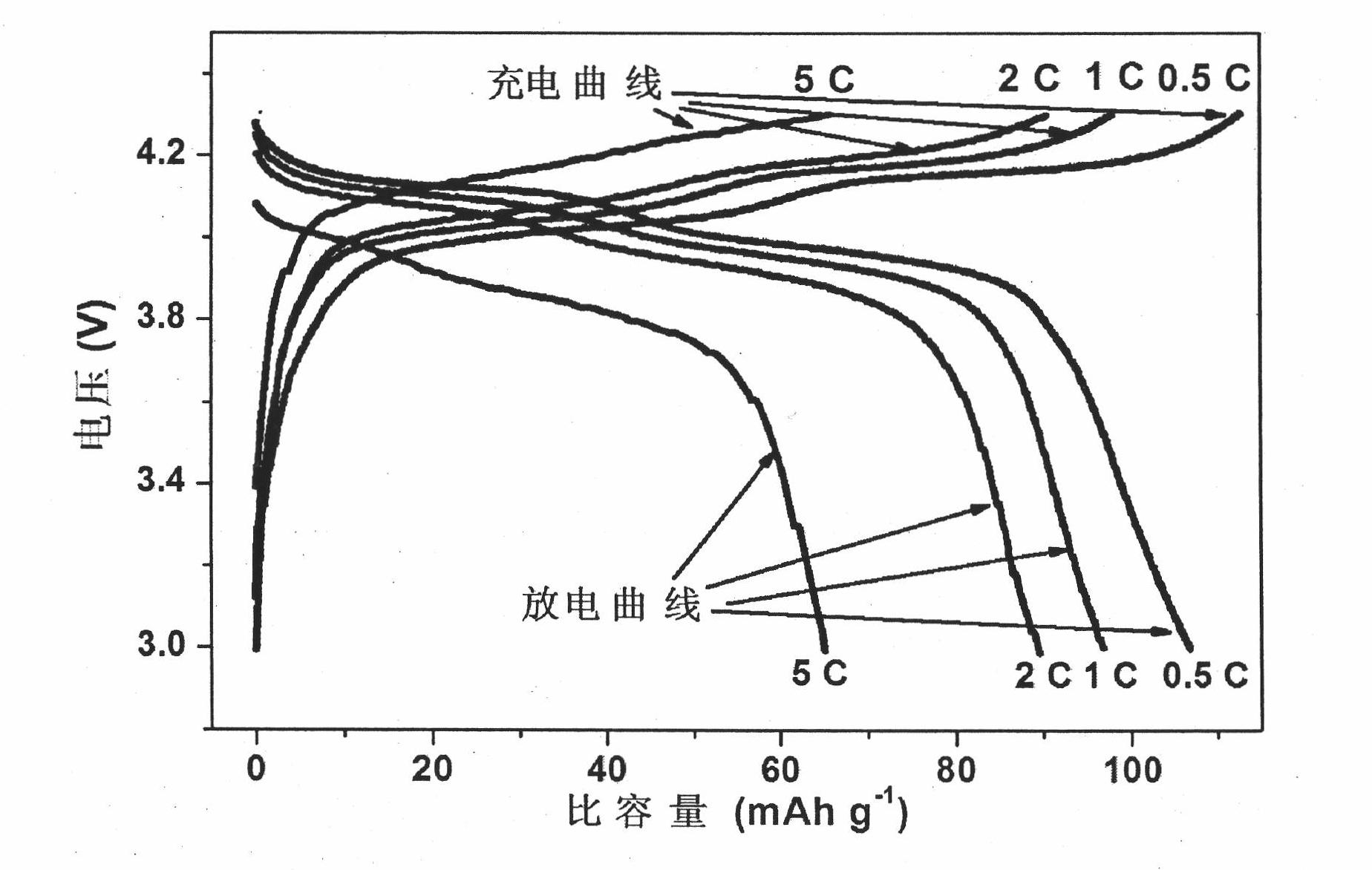

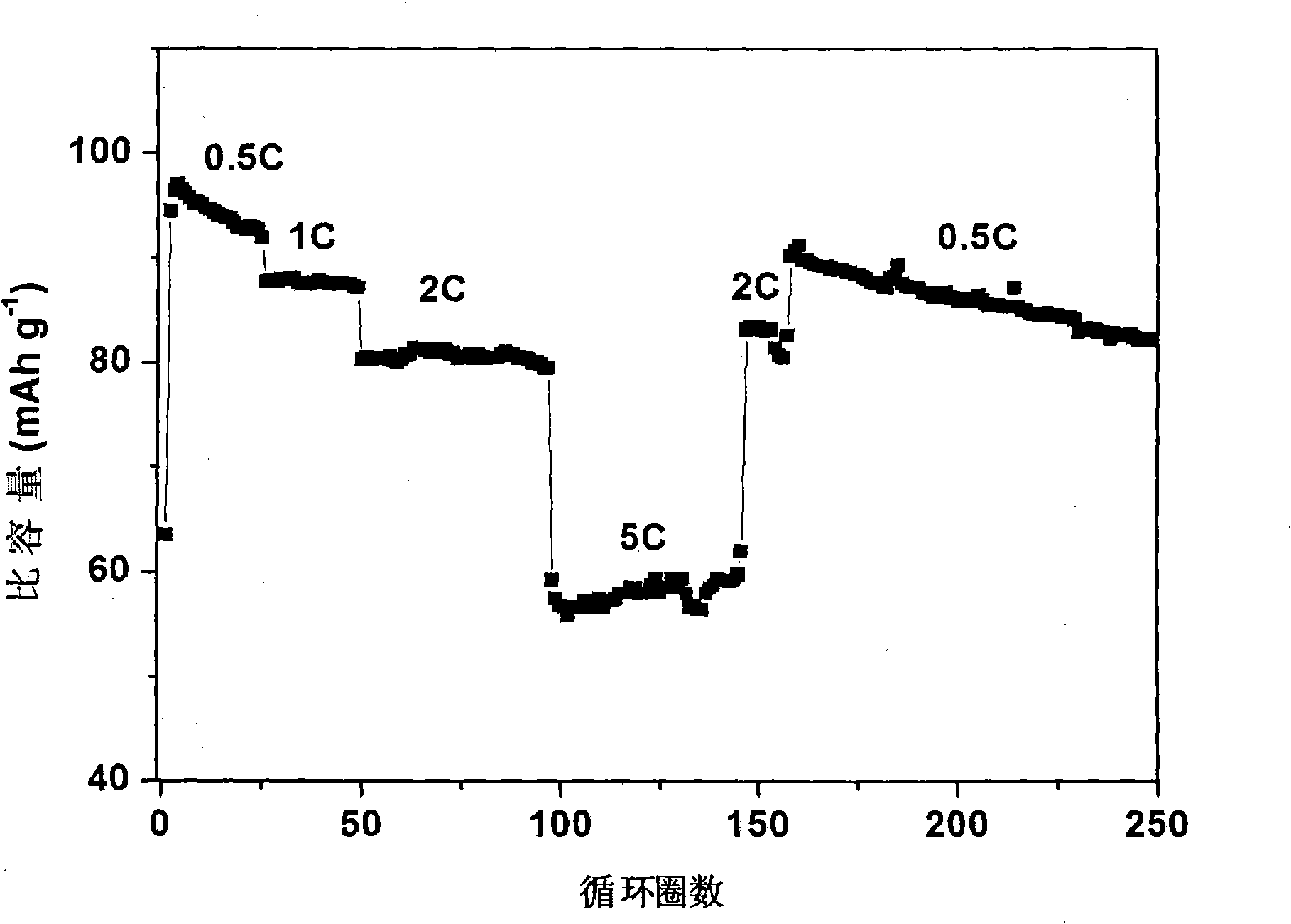

[0022] The invention provides a method for preparing a cathode electrode material of a micron frame-shaped manganese-based lithium ion battery. The invention will be further described below in conjunction with the accompanying drawings and examples.

[0023] Preparation of LiMn 2 o 4 The embodiment of micron frame shape manganese series lithium ion battery cathode electrode material:

[0024] (1) 4.42 g of KMnO 4 and 3.5 grams of sucrose were fully dissolved in 140 mL of deionized water respectively to obtain KMnO with a concentration of 31.5 g / L 4 solution and 25g / L sucrose solution;

[0025] (2) After the above two solutions were mixed and stirred for 20 minutes, the resulting solution was transferred to a hydrothermal kettle with a polytetrafluoroethylene liner. The filling degree was 80%, and the lid of the kettle was tightly sealed. After reacting for 24 hours, take out the reaction kettle and cool it naturally in the air, and repeatedly wash the precipitate with deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com