Novel method for preparing 3-hydroxylquinaldine-4-carboxylic acid

A new method, the technology of hydroxyquinaldine, applied in the high-purity field, can solve the problems of dye dispersibility, poor level dyeing, low dye strength, 3-hydroxyquinaldine-4 carboxylic acid content, low purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

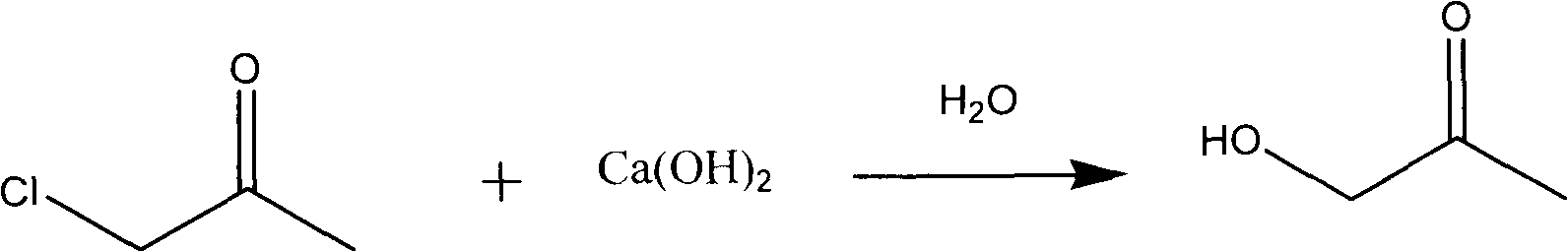

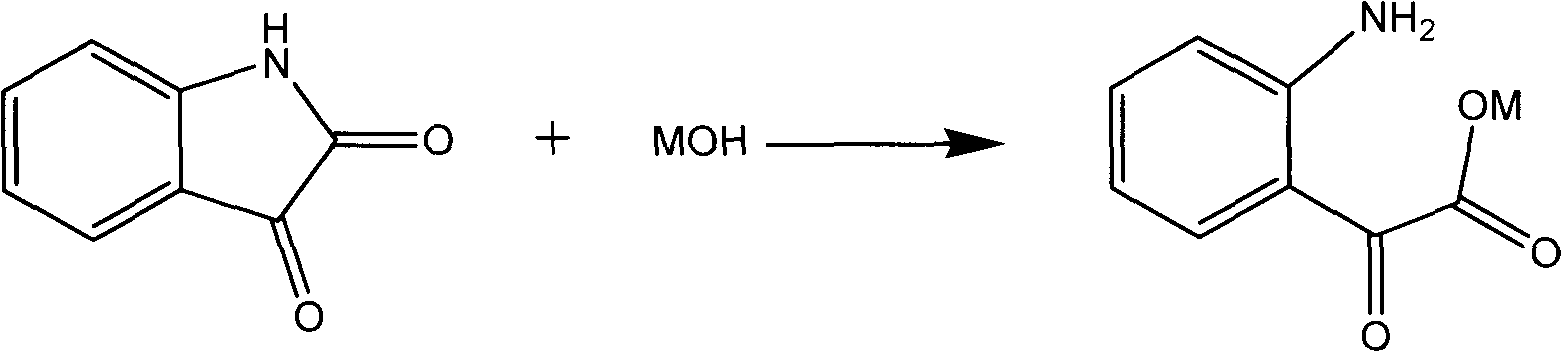

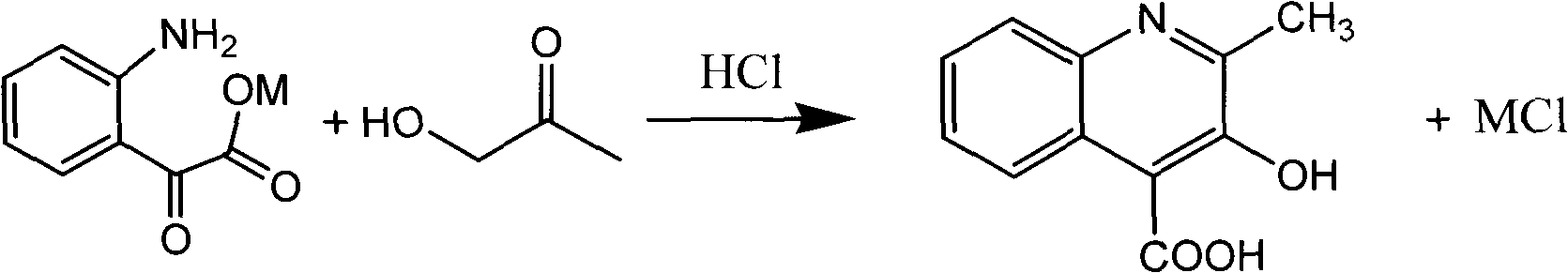

Method used

Image

Examples

Embodiment 1

[0020] Example 1: 1. Take 1.0 mol of solid isatin, add it to 1224 ml of clear water, stir to dissolve, and filter out insoluble solids, add 1.0 mol of sodium hydroxide, mix and dissolve, filter, and collect the filtrate;

[0021] 2. Add 1.0 mol of sodium hydroxide to the obtained filtrate, dropwise add 1.0 mol of monochloroacetone, and dropwise add hydrochloric acid to adjust PH=7, then discharge and filter, collect the filter cake, and dry to obtain 196.96 grams of dry matter , detected by high-pressure liquid chromatography (HPLC), the purity is 98%, the yield is 95%, and the dissolution temperature is controlled between 10-80°C.

Embodiment 2

[0022] Embodiment 2: the consumption of monochloroacetone is increased to 1.5mol, and dissolution temperature is controlled between 45~55 ℃, repeats embodiment 1, obtains 196.37 grams of dry matter, detects through high pressure liquid chromatography (HPLC), and purity is 98.5%, the yield is 95.2%, and the dissolution temperature is controlled between 10-80°C.

Embodiment 3

[0023] Embodiment 3: the consumption of monochloroacetone is increased to 2mol, and dissolution temperature is controlled between 45~55 ℃, repeats Example 1, obtains 200.05 grams of dry matter, detects through high-pressure liquid chromatography (HPLC), and purity is 97.5 %, the yield is 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com