Construction method of beddings of foundation downward overturn beam and pile cap

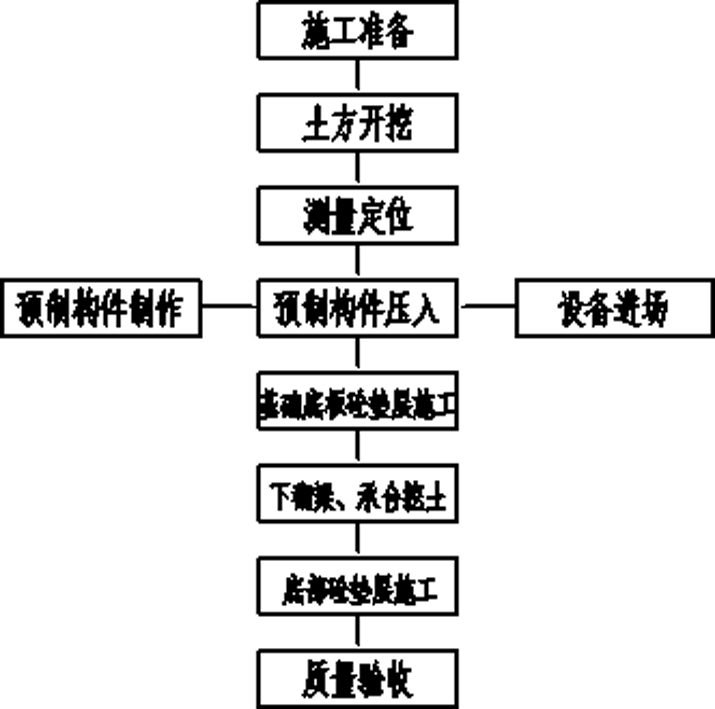

A construction method and cushioning technology, which are applied in the direction of infrastructure engineering and construction, can solve the problems of high labor intensity, brick membrane damage, cracks, etc., reduce construction procedures and engineering quantities, speed up construction progress, and maximize lateral The effect of earth pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

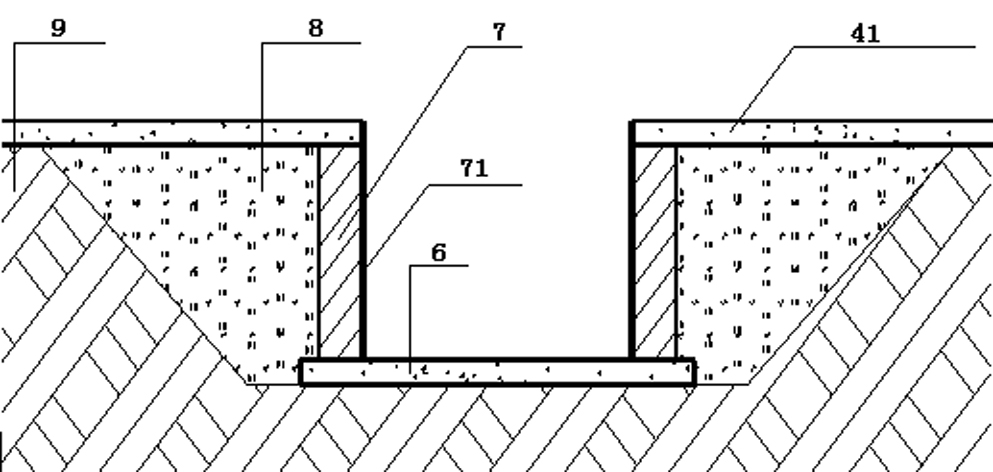

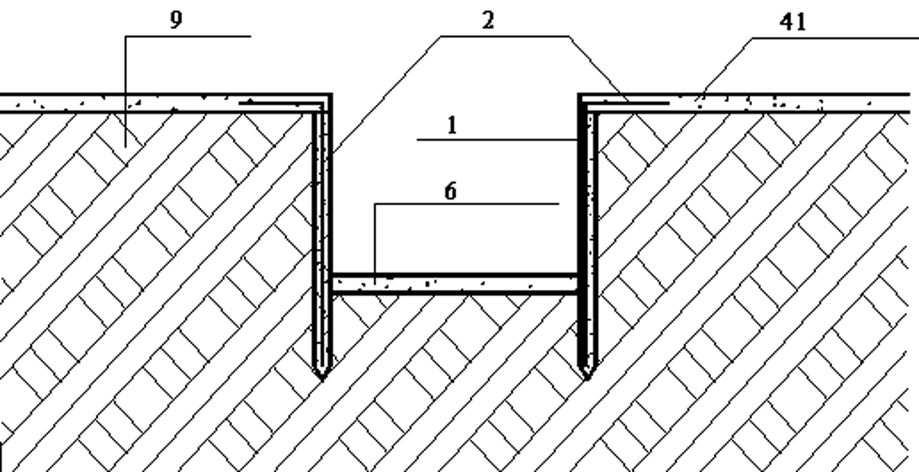

[0038] Refer to attached picture.

[0039] The construction method of the underturned beam under the foundation and the cap cushion of the present invention includes the step of preparing a prefabricated component 1, the prefabricated component 1 is a concrete component, the prefabricated component 1 includes a steel mesh sheet 2 and a prefabricated slab 3, and the prefabricated slab 3 is poured by concrete The reinforced mesh 2 includes a pressed mesh 21 and a reserved mesh 22. The pressed mesh 21 is anchored into the prefabricated slab 3 during the casting process of the prefabricated slab 3, and the reserved mesh 22 extends out of the prefabricated slab 3 outside and perpendicular to the pressed mesh 21;

[0040] The strength of the prefabricated components is not lower than C25, the thickness of the prefabricated slab is 6-10cm, the width of the prefabricated slab is controlled within 1.5m, and the length of the prefabricated slab is 1.5 times the depth of the downturning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com