Processing method for protecting excavation place of shield machine from mudlining

A technology of shield machine and mud formation, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., and can solve the problems of weakening effect, failure to achieve effect, increasing cutterhead torque, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

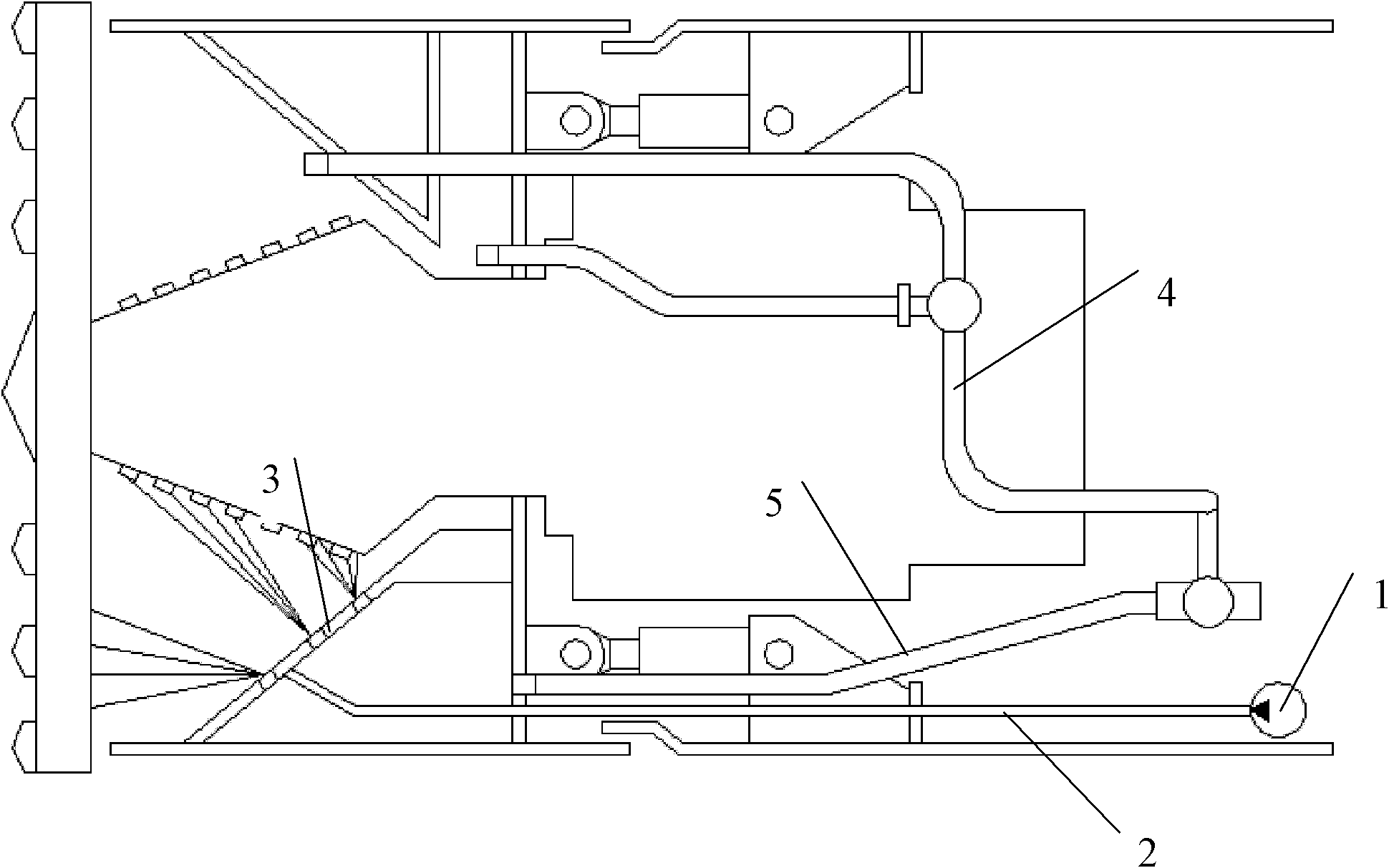

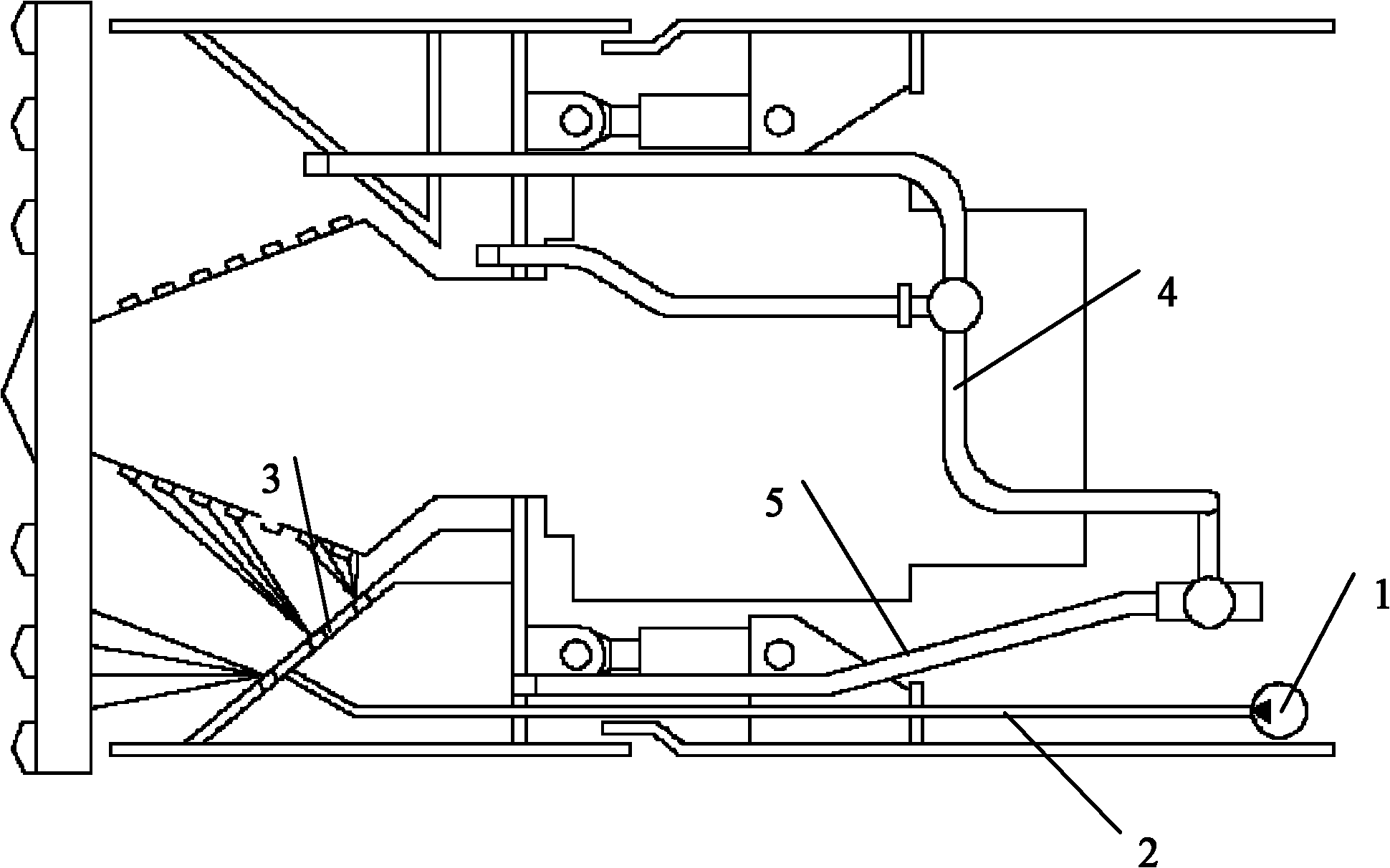

[0009] Referring to the accompanying drawings, a method for preventing the formation of mud cakes at the excavation of the shield machine, as the cutter head rotates, the cut muck enters the conical crushing chamber through the hole on the cutter head, and connects with the slurry feeding pipeline 4 The injected slurry is mixed to form high-density slurry, which is transported to the outside of the cave by the slurry discharge pipeline 5; when the shield machine passes through the super-clay stratum, a large amount of hard plastic clay sticks to the cutter head and the cone-shaped broken body, due to the high clay content , resulting in more clay sticking to the cutter and the cone-shaped broken body, resulting in an increase in the torque of the cutterhead, making it impossible to move forward smoothly, and the shield construction is in trouble; it is used under ultra-clay soil conditions to prevent mud cake formation at the excavation of the shield machine method, when the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com