Finger-jointed board of fluorescent wood-plastic or bamboo-plastic composite

A finger-jointed board and wood-plastic technology, applied in sheet/board, dovetail processing, wood processing equipment, etc., can solve the problems that cannot meet the needs of art decoration, single wood-plastic or bamboo-plastic material styles, and board deformation. To achieve the effect of rich and colorful decorative arts, ornamental and upgrading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

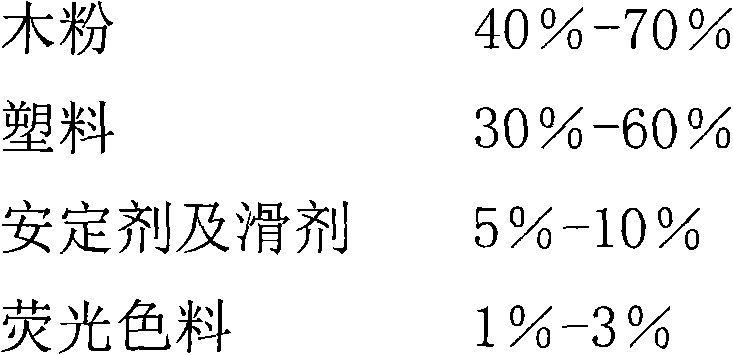

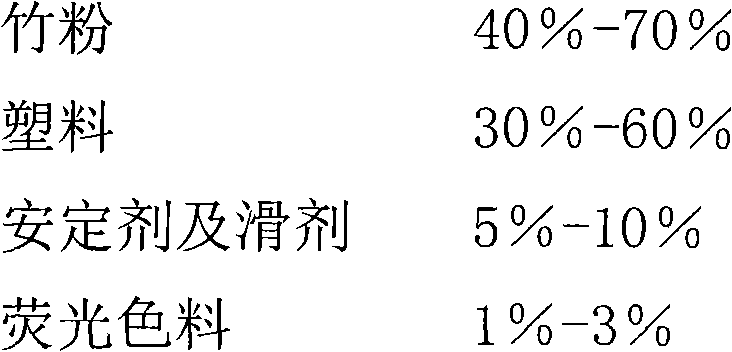

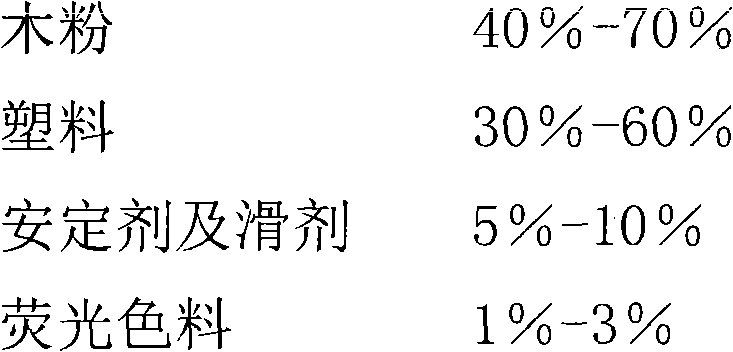

[0027] A fluorescent wood-plastic or bamboo-plastic finger-joint board is mainly a wood-plastic or bamboo-plastic board. During the production process of wood-plastic or bamboo-plastic, fluorescent pigments are added, and the finished wood-plastic or bamboo-plastic board is processed Splicing and molding, wood-plastic or bamboo-plastic panels are made into profiles of different lengths and sizes. Tenons and tenon grooves are respectively set on the adjacent sections of each wood-plastic or bamboo-plastic panel. Through the cooperation of tenon and tenon grooves, the Adjacent profiles are cross-fingered together to form a whole plate. Wherein the tenon length is 3-5mm, the thickness is 2-4mm, the depth of the adjacent tenon groove is 3-5mm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com