Blast furnace-rotary furnace section scheduling system modeling method based on queuing theory and system simulation

A system simulation and scheduling system technology, applied in the field of information, can solve the problems of great impact on transportation costs, and achieve the effect of reducing operating costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

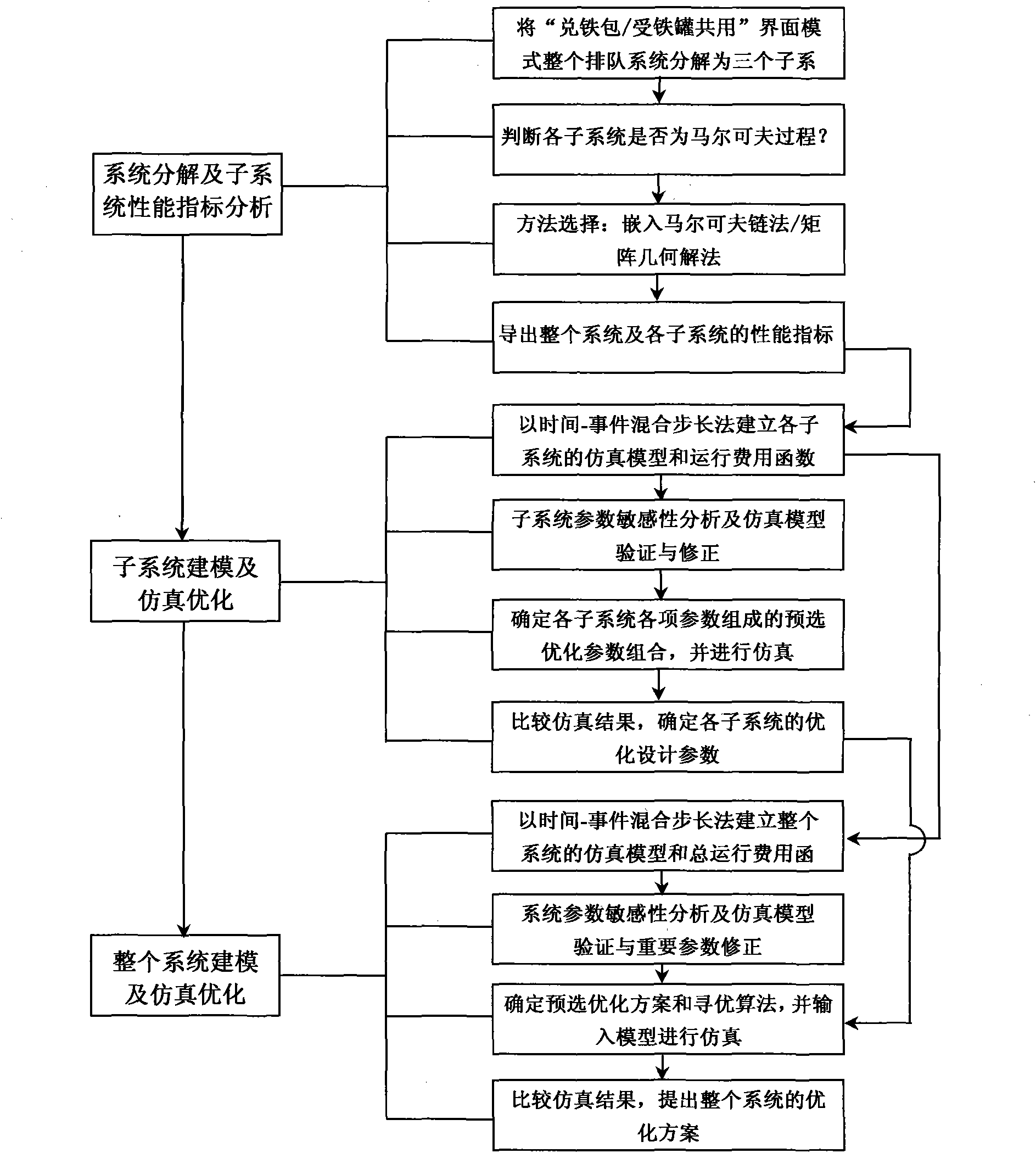

[0022] Using the modeling method of blast furnace-converter section scheduling system based on queuing theory and system simulation, the blast furnace-converter section scheduling system mainly includes the following steps:

[0023] (1) Production data acquisition and processing

[0024] Through the on-site investigation and relevant data measurement of typical iron and steel enterprises adopting the interface mode of "ladle ladle / can sharing" to master the blast furnace, converter smelting cycle, maintenance cycle, and failure frequency , hourly output, utilization factor, tapping / mixing time rhythm, statistical data on the arrival / departure of several cans per car and the time interval of arrival / departure, the main equipment and the queuing method of molten iron tanks in front of the tank inspection station and shunting yard , Waiting time, transportation route layout, distance, locomotive empty / heavy train running speed, traffic density, statistical data of molten iron tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com