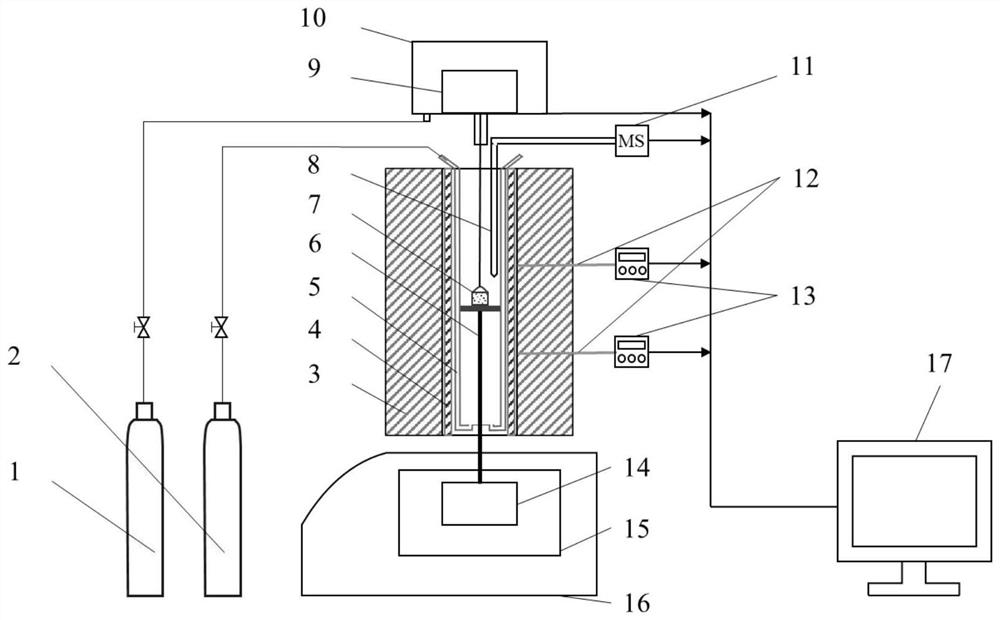

Pulse heating coupling in-situ sampling thermogravimetric-mass spectrometry combined equipment

A pulse heating and in-situ technology, applied in the field of analytical instruments, can solve problems such as reaction process distortion and detection distortion, and achieve high integration, minimized secondary reactions, and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] It should be noted that the terms "first", "second" and the like in the description and claims of the present invention and the above drawings are used to distinguish similar objects, and are not necessarily used to describe a specific sequence or sequence. It is to be understood that the data so used may be interchanged under appropriate circumstances such that the embodiments of the invention described herein can be practiced in sequences other than those illustrated or described herein. In addition, the terms "comprising" and "having" and any variations thereof in the embodiments of the present invention are intended to cover non-exclusive inclusion, for example, a process, method, system, product or device comprising a series of steps or units is not necessarily limited to Those steps or elements that are expressly listed may instead include other steps or elements that are not expressly listed or are inherent to the process, method, product or apparatus.

[0033] I...

Embodiment 1

[0047] 1) Place the equipment on the test bench with a flat and level surface, and adjust the bottom adjusting stud to make the balance in a horizontal state.

[0048] 2) Turn on the regulated power supply, workstation, gas flow meter, and computer host in turn, and open the nitrogen bottle to make the pressure 0.5MP.

[0049] 3) Open the lifting device controlled by the data analysis unit 17 , take out the clean sample holder 6 and insert it vertically into the circular support frame channel from top to bottom, and place the clean empty sample crucible 7 on the sample holder 6 .

[0050] 4) Control the lifting device to open and close the furnace through the data analysis unit 17, adjust zero on the operation interface, and deduct the weight of the empty crucible.

[0051] 5) Write the reaction heating program, start the balance, and carry out the blank experiment.

[0052] 6) Weigh 30mg-50mg calcium oxalate with an electronic analytical balance.

[0053] 7) After the blank...

Embodiment 2

[0056] Replace the experimental sample with coal tar and repeat the relevant steps of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com