Forming method of N-channel metal oxide semiconductor (NMOS) transistor

A technology of transistors and semiconductors, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of device characteristic drift, fast threshold voltage rise in channel region, uneven ion distribution in Vt implantation region, etc., to prevent reverse reaction The effect of short channel effect and uniform distribution of ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

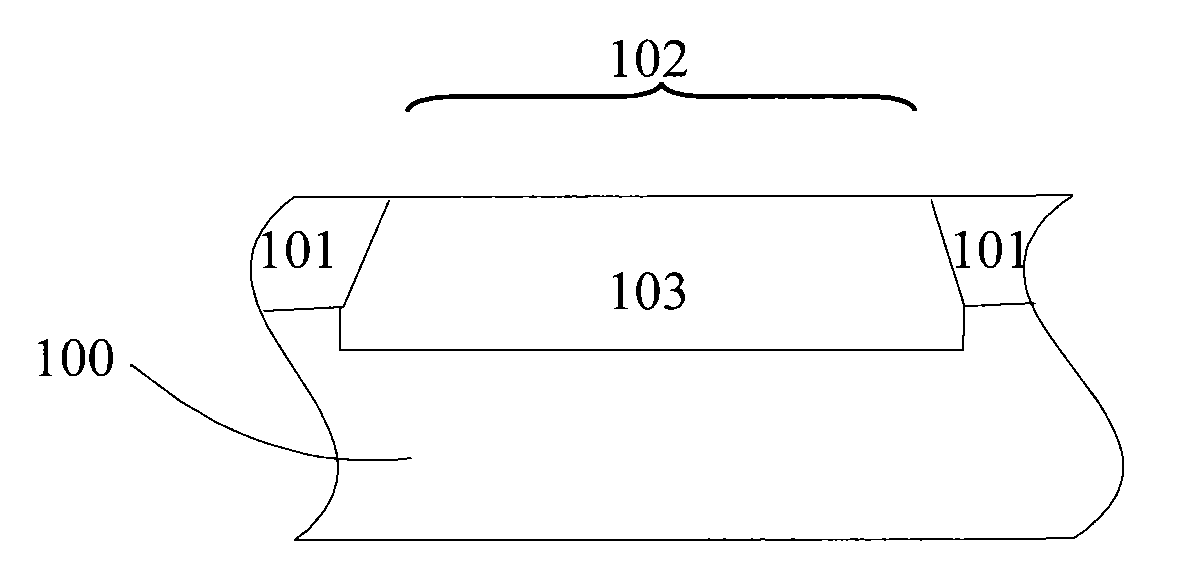

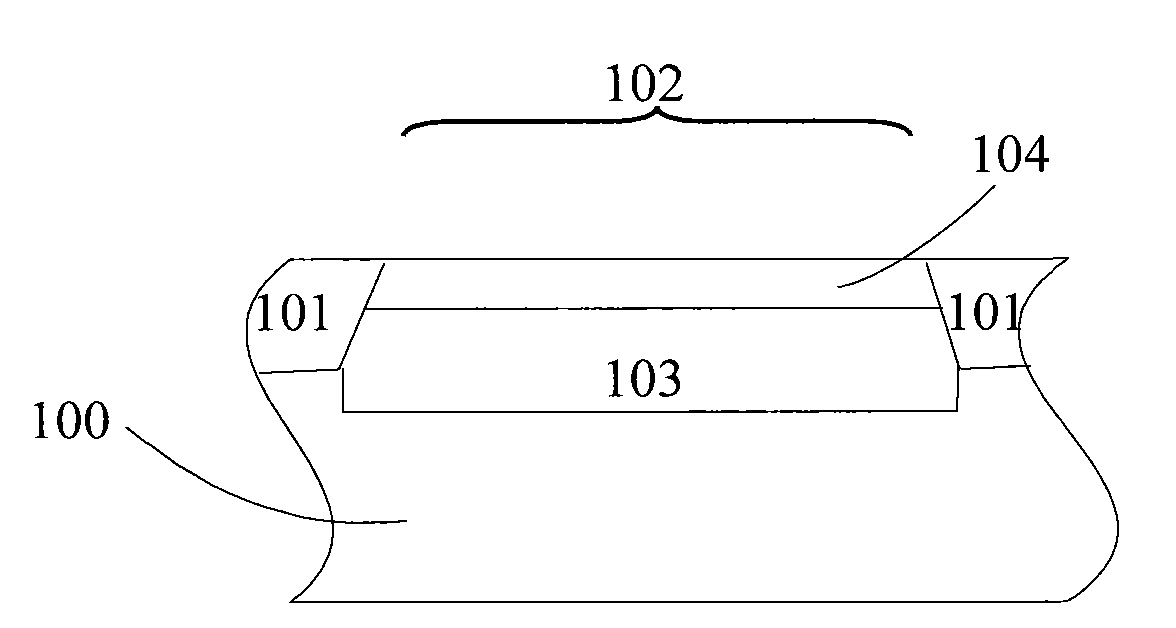

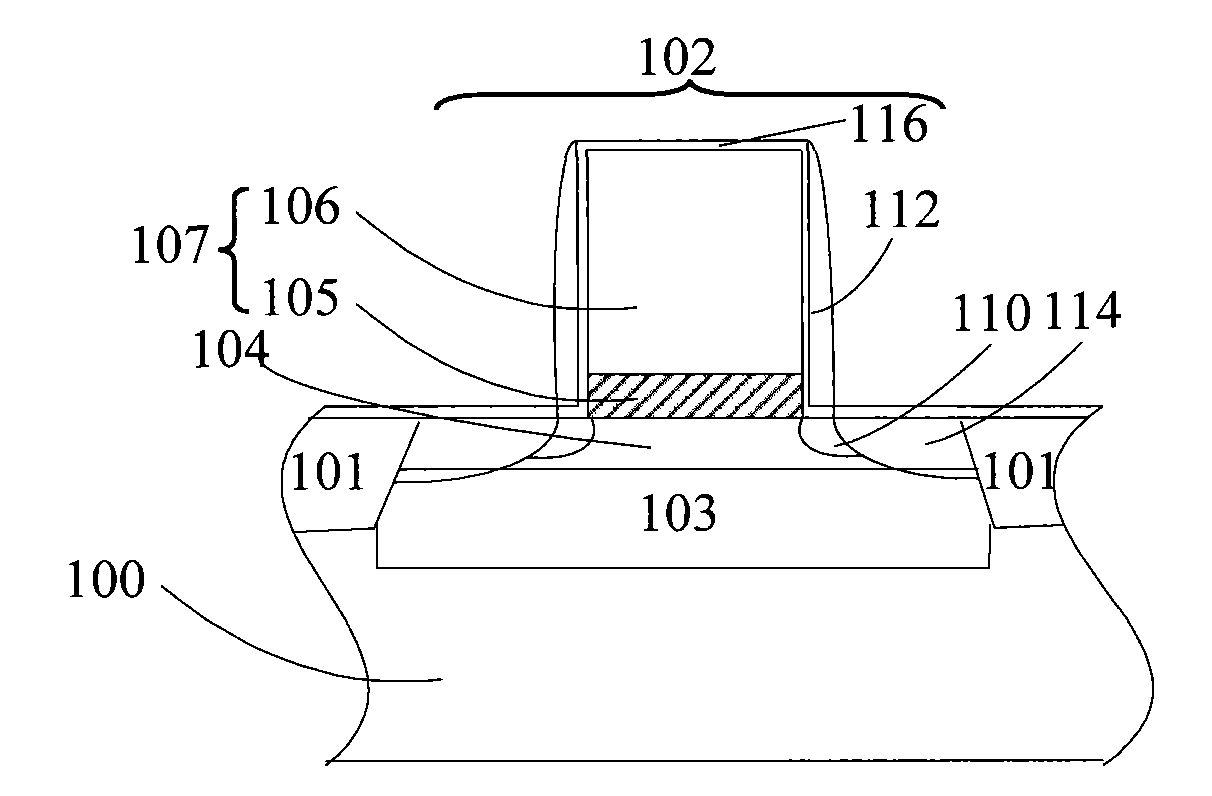

[0019] The specific implementation process of forming NMOS transistors in the present invention is as follows: Figure 4 As shown, step S1 is executed to provide a semiconductor substrate, and the semiconductor substrate is divided into an isolation region and an active region; step S2 is executed to form a doped well in the semiconductor substrate in the active region; step S3 is executed to form a doped well in the active region A gate dielectric layer and a gate are sequentially formed on the semiconductor substrate in the source region, and the gate dielectric layer and the gate form a gate structure; step S4 is performed to re-oxidize the gate structure; step S5 is performed to take the gate structure as Mask, implanting ions into the semiconductor substrate on both sides of the gate to form source / drain extension regions; performing step S6, forming Vt implantation regions in the semiconductor substrate after forming sidewalls on both sides of the gate structure; Step S7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com