Battery engine

A battery and engine technology, applied in battery circuit devices, secondary battery repair/maintenance, measurement of electricity, etc., can solve the problems of inconsistent charging and discharging, shortening battery system life, affecting battery performance, etc., to avoid the trouble of replacing batteries, Avoid failure to work properly and ensure the effect of uninterrupted operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

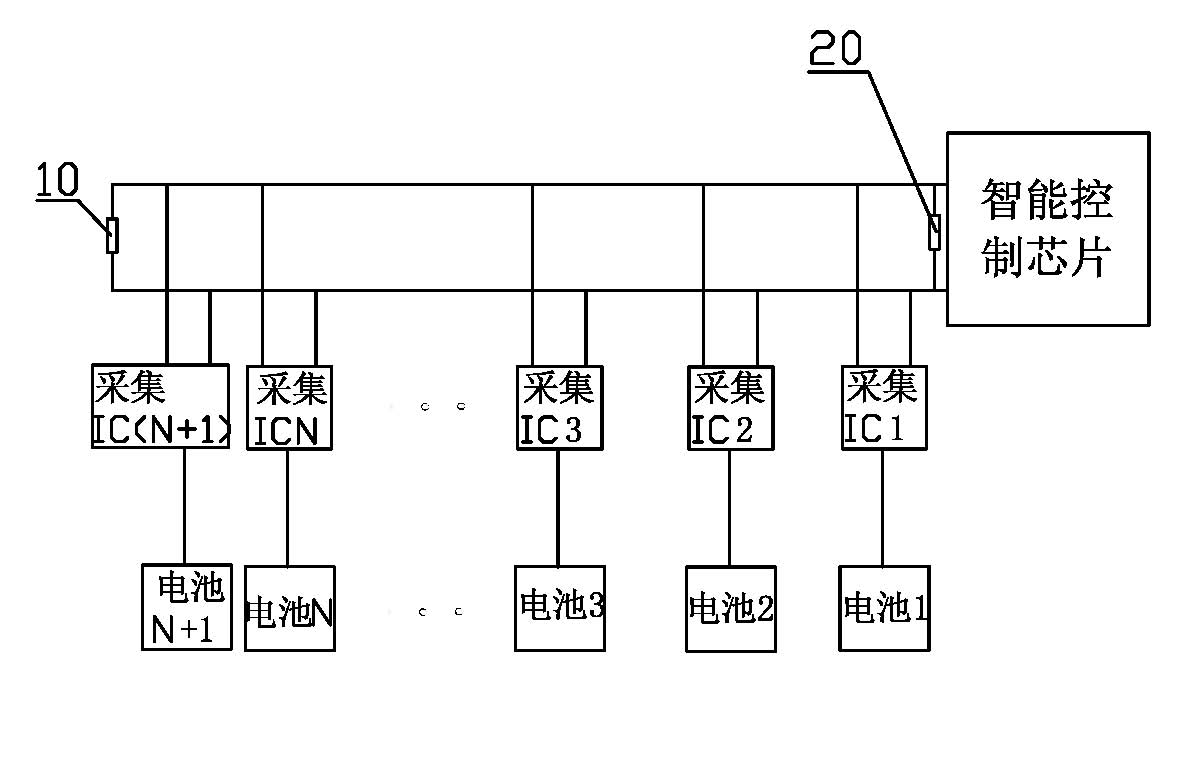

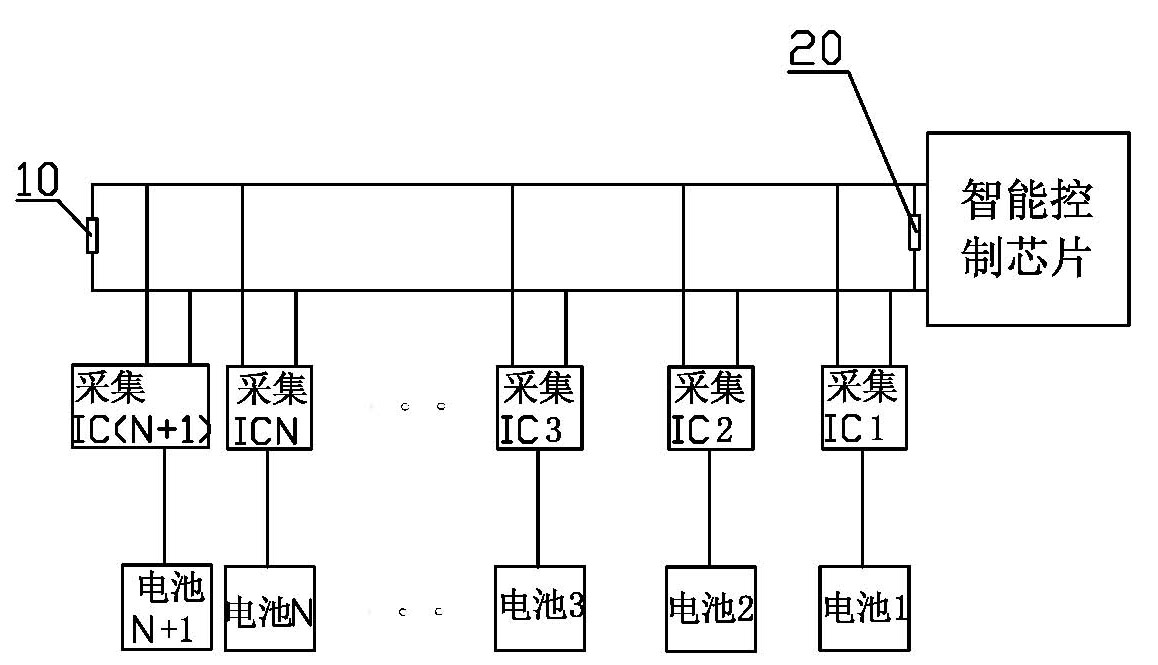

[0023] Such as figure 1 As shown, the battery box managed by the battery engine includes (N+1) batteries connected in series, wherein the number of working batteries is N, and the (N+1)th battery is a backup battery and is in a standby state. The battery engine includes a data acquisition module and an intelligent control chip. The data acquisition module includes (N+1) acquisition ICs, each acquisition IC is respectively connected to the positive and negative signals of (N+1) batteries in the battery box, and each acquisition IC is connected in parallel to the intelligent control chip , and simultaneously connect two resistors 10 and 20 in parallel, and the two resistors 10 and 20 are external resistors of the intelligent control chip. The internal circuit structure and function of each acquisition IC are the same.

[0024] Each acquisition IC includes a battery information measurement circuit, a temperature sensor, a protection circuit, and a state acquisition circuit.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com