Equipment and method for preparing uniform dripping pills

A dripping pill and uniform technology, which is applied in the direction of making medicine into a special physical or taking form of the device, can solve the problems of low production capacity and large difference in pill weight, etc., and achieve high product efficiency, reduce waste rate, and roundness Good effect of sex and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

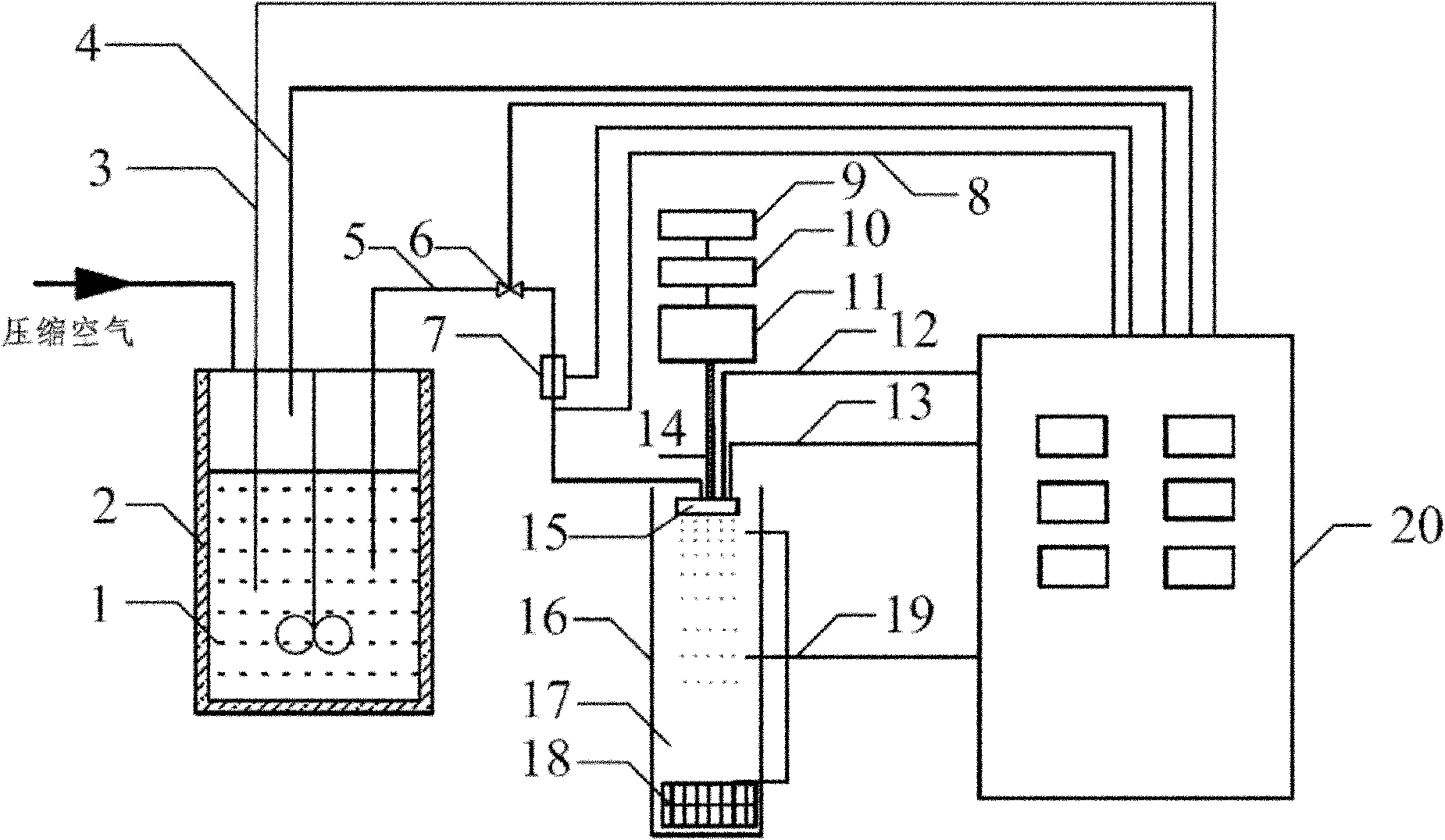

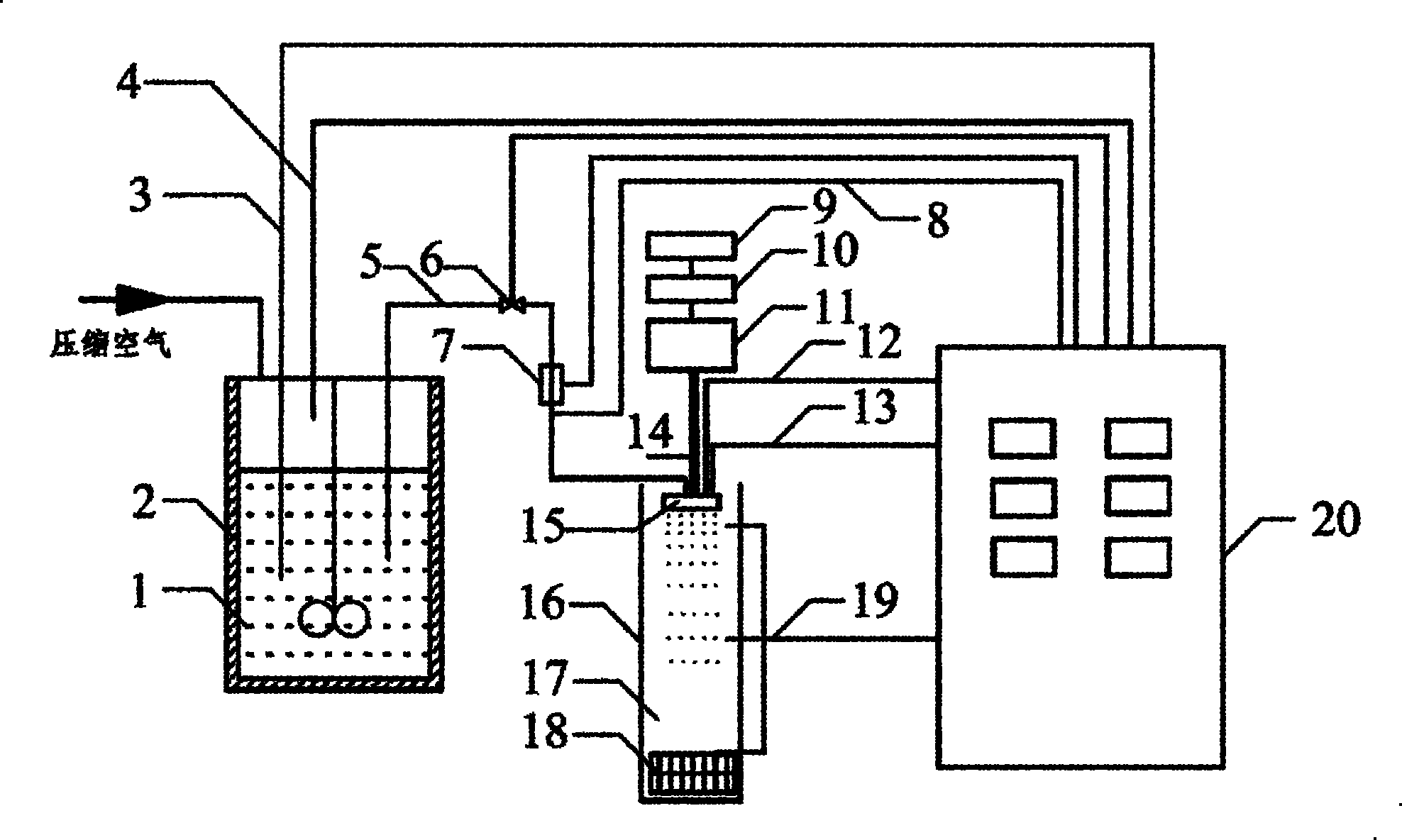

Method used

Image

Examples

Embodiment 1

[0033] The drug is nifedipine, the auxiliary materials are polyethylene glycol (PEG) 4000 and (PEG) 6000, the ratio of the two is 5:1, and the ratio of the auxiliary materials to the drug is 5:1. The height of the cooling column is 2m, and dimethyl silicone oil is used as the cooling liquid. The upper part of the cooling column is set at 120°C, the middle part is room temperature, and the lower part is 5°C. When the nozzle diameter is 0.3mm, the number of nozzles is 3, and they are arranged in an equilateral triangle, the pressure of the molten chemical liquid is 0.05MPa, the jet velocity at the nozzle is about 1.6m / s, the set temperature is 135°C, and the vibration frequency is set to 200Hz, the amplitude is 0.15mm, and the diameter of the prepared dripping pills is 1.5mm ± 0.05mm, and the dripping pills account for 98% of the total mass; The hydraulic pressurization is 0.06MPa, and the jet flow velocity of the orifice at the nozzle is about 1.8m / s. The temperature is set at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com