Multi-motion mode planetary workpiece rest of vacuum coating machine

A vacuum coating machine, planetary technology, applied in the direction of vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the difficulty of arrangement and sealing performance guarantee, the complex structure of the multifunctional workpiece rack, and the inconvenience of operation for experimenters and other problems, to achieve the effect of simple and reasonable structure, simple structure, convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings and embodiments.

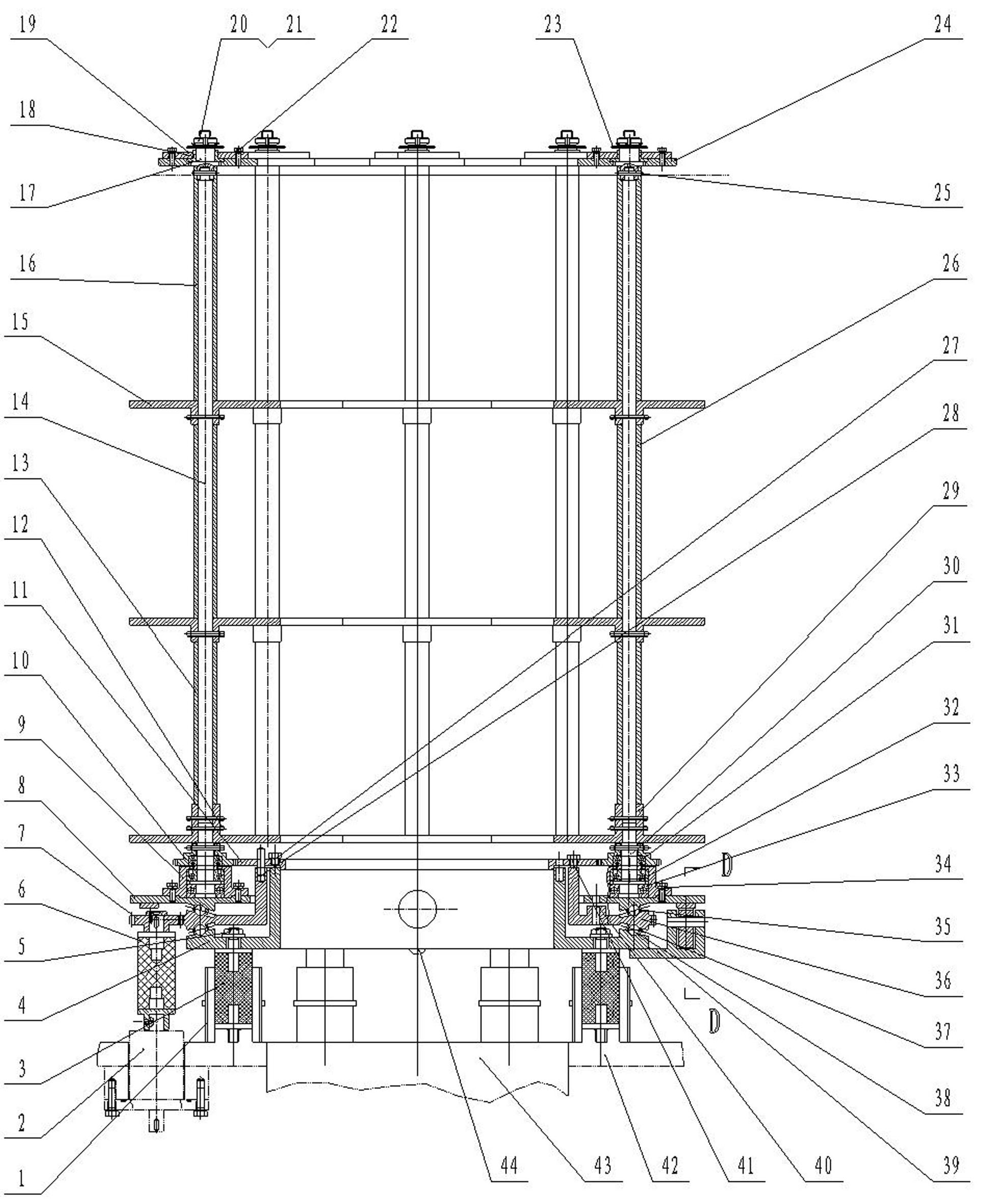

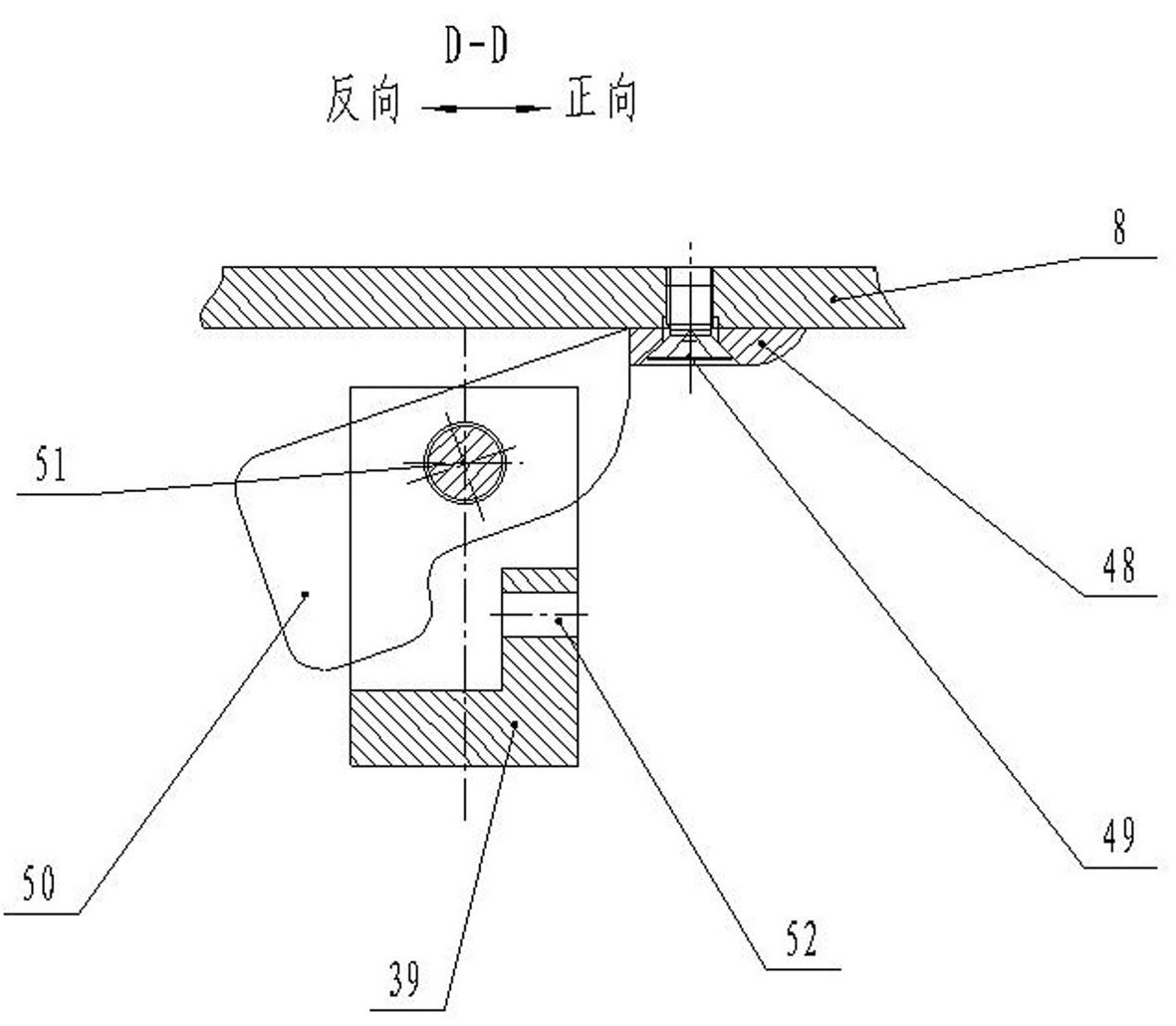

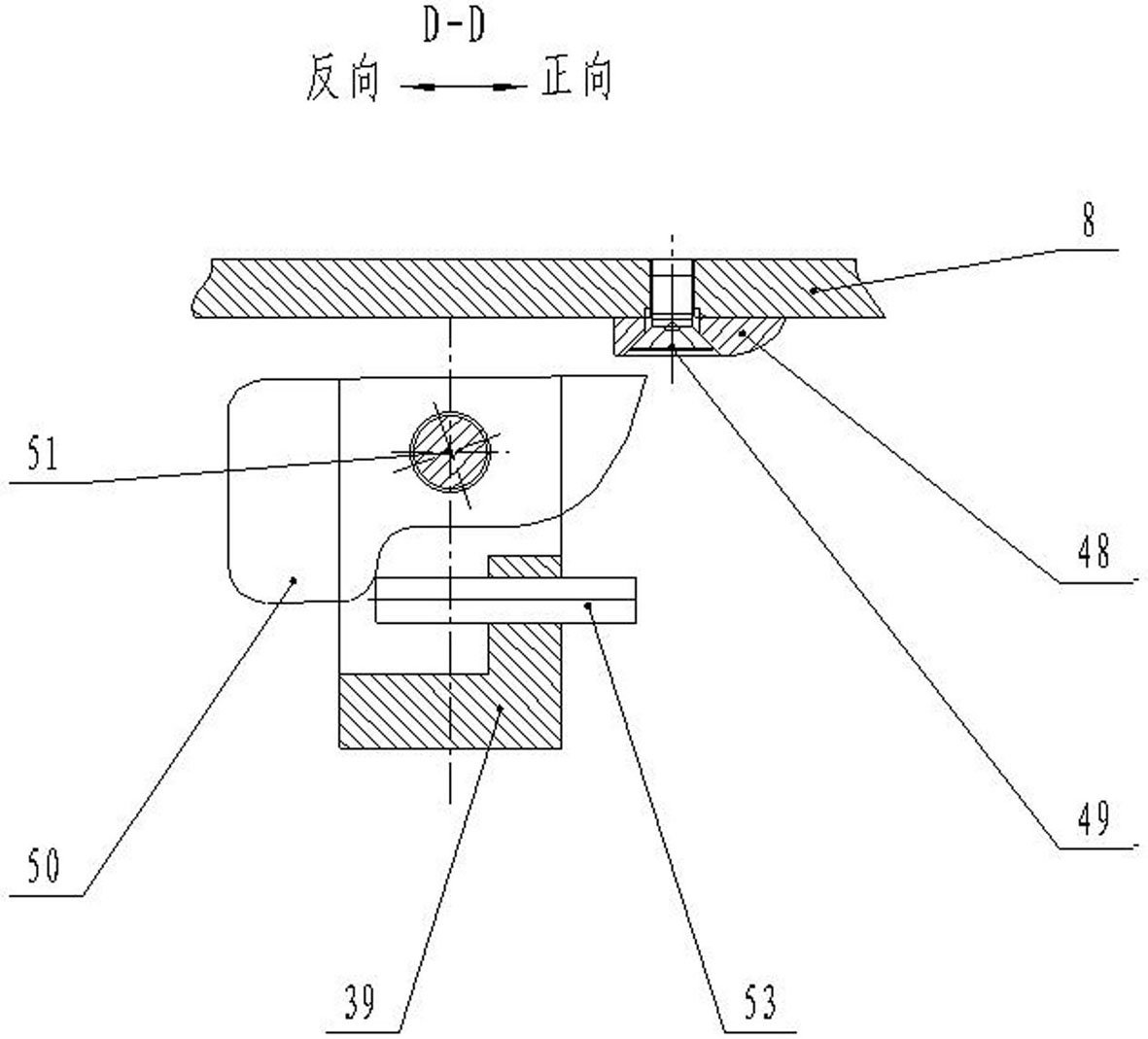

[0025] A planetary workpiece rack of a vacuum coating machine in a multi-movement mode of the present invention has a specific structure as follows: on the bottom plate 42 of the coating vacuum chamber, the lower support plate 4 of the workpiece rack is held up and fixed by a plurality of insulating support seats 3; Above the plate 4, the balls 38 constrained by the lower ball cage 37 hold up the middle support plate 36, and then the balls constrained by the upper ball cage 35 support the upper support plate 8. The ball slides between the three layers of support plates are: Inclined surface; the insulating support base 3 is arranged on the annular circumference of the vacuum chamber bottom plate 42, so that the vacuum chamber exhaust port 43 is arranged in the center of the vacuum chamber bottom plate 42; such as figure 1 As shown, the upper support plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com