Reciprocating double-plunger pump oil supply device

A technology of double plunger pump and oil supply device, which is applied in the direction of piston pump, pump, pump control, etc. It can solve problems such as difficulty in starting, small torque of low-power linear motor, high price of high-power linear motor, etc., and achieve dynamic Good performance, stable work and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

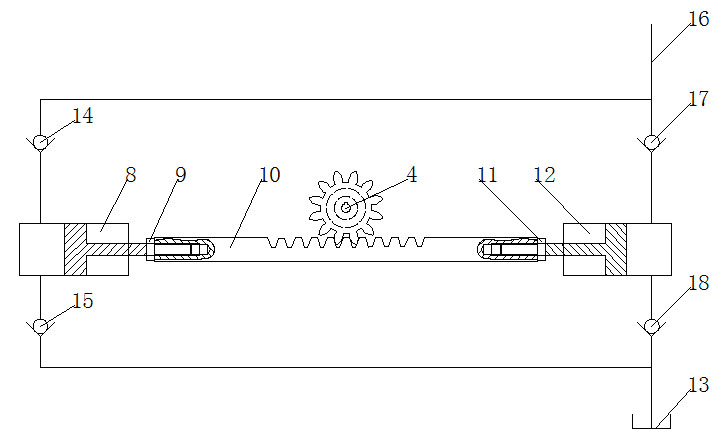

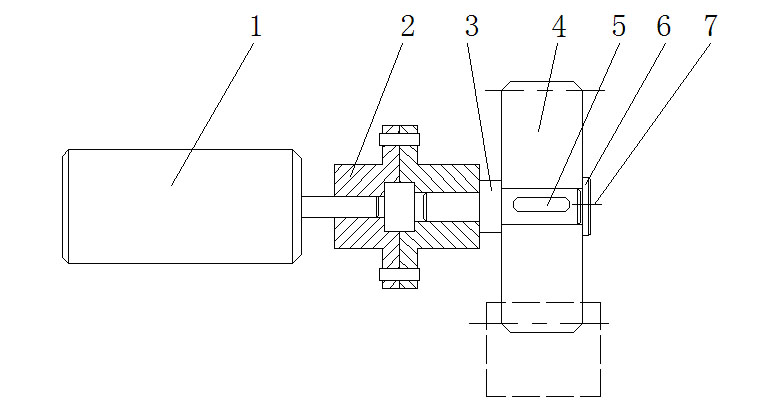

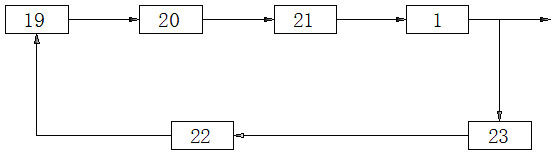

[0020] Example 1: See first figure 1 — figure 2 shown. figure 1 It is a structural front view of the reciprocating double plunger pump oil supply device of the present invention, figure 2 It is a left view of the structure of the reciprocating double plunger pump oil supply device of the present invention. The reciprocating double plunger pump oil supply device proposed by the present invention includes a rotating motor, a rack and pinion, two plunger pumps, a coupling, two oil suction check valves, two oil discharge check valves and a drive control system . in:

[0021] The output shaft of the rotary motor 1 performs rotary motion, the linear motor 1 transmits the rotary motion to the gear shaft 3 through the coupling 2, and the gear shaft 3 transmits the motion to the gear 4 through the key 5; the gear 4 is installed on the gear shaft , the left end is positioned by the shaft shoulder, and the right end is positioned by the bearing end cover 6; the bearing end cover 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com