Breathable material for cauldron

A technology for gas-permeable materials and furnaces, applied in the field of gas-permeable components, can solve problems such as productivity decline, defects, deformation and transportation of furnaces, and achieve the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

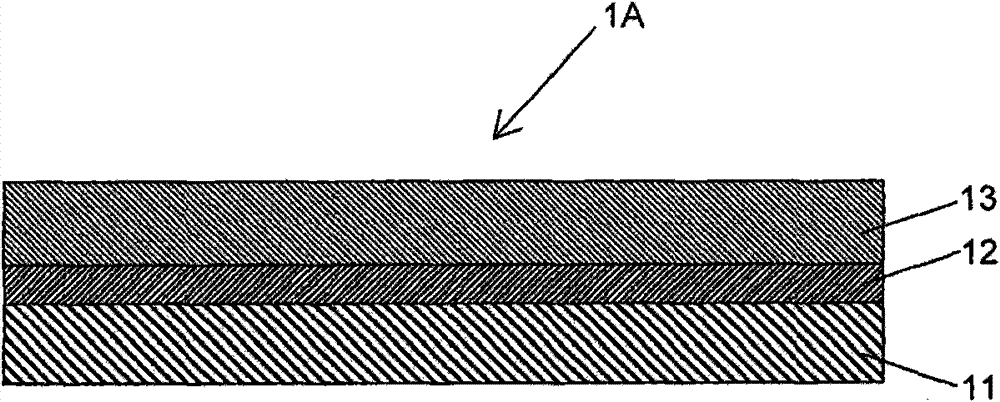

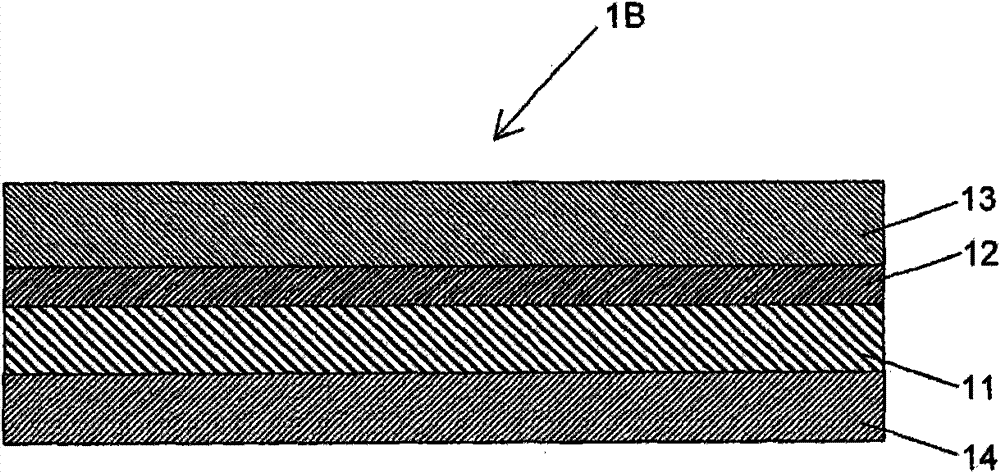

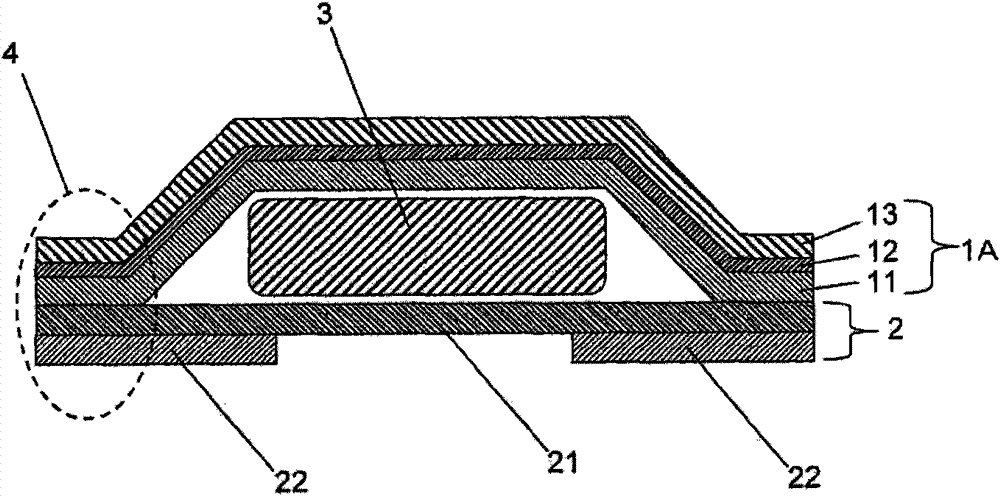

[0122] (non-woven fabric)

[0123] As the non-woven fabric, a spun-bonded non-woven fabric (embossed area ratio 11%, basis weight 30 g / m 2 ). ,

[0124] In addition, the area of each embossing of the above-mentioned nonwoven fabric is 1.2mm 2 .

[0125] (porous film)

[0126] 100 parts by weight of linear low-density polyethylene (Mw: 60,000, MFR (190°C) 2.3g / 10min), ethylene-α-olefin copolymer (Mw: 112,000, ) is 3.6g / 10 minutes), 40 parts by weight, calcium carbonate (average particle diameter: 1.1 μm) 140 parts by weight, 1 part by weight of stearic acid and 1 part by weight of antioxidant are melt-kneaded to obtain a mixed raw material.

[0127] Using the above mixed raw materials, melt-extrude by T-die method, and stretch along the length (MD) direction at a stretching temperature of 100°C at a stretching ratio of 4 times by a uniaxial roll stretching method to obtain a thickness 70μm polyethylene porous film.

[0128] (adhesive)

[0129] As the adhesive, a hot-m...

Embodiment 2

[0135] In addition to changing the non-woven fabric to a spun-bonded non-woven fabric manufactured by a spunbond method (embossed area ratio 13%, basis weight 30g / m2) containing PBT fibers 2 , The area of each embossing is 0.6mm 2 ) except that a breathable material was obtained in the same manner as in Example 1. The compressive strength (ring pressure method, MD direction) of the breathable material is 4.3N, and the wear resistance is grade 4.

Embodiment 3

[0137] Using a spunbonded nonwoven fabric made of PET fibers by a spunbond method (embossed area ratio 11%, basis weight 20g / m 2 , The area of each embossing is 1.2mm 2 ) and spunlace non-woven fabrics containing PET fibers made by spunlace (basis weight 20g / m 2 ) composite non-woven fabric as a non-woven fabric.

[0138] Except having changed the nonwoven fabric into the said composite nonwoven fabric, it carried out similarly to Example 1, and obtained the air-permeable material. In addition, an adhesive layer was formed on the surface of the composite nonwoven fabric on the side of the spunbonded nonwoven fabric, and a porous film was bonded thereto.

[0139] The compressive strength (ring pressure method, MD direction) of the breathable material is 2.9N, and the wear resistance is grade 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| base weight | aaaaa | aaaaa |

| base weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com