Ultrasonic pressure sensor and operation method thereof

A pressure sensor, ultrasonic technology, applied in the direction of fluid pressure measurement, instrumentation, measurement force, etc. using acoustic methods, which can solve problems affecting sensor performance, changes, and limited sensor capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

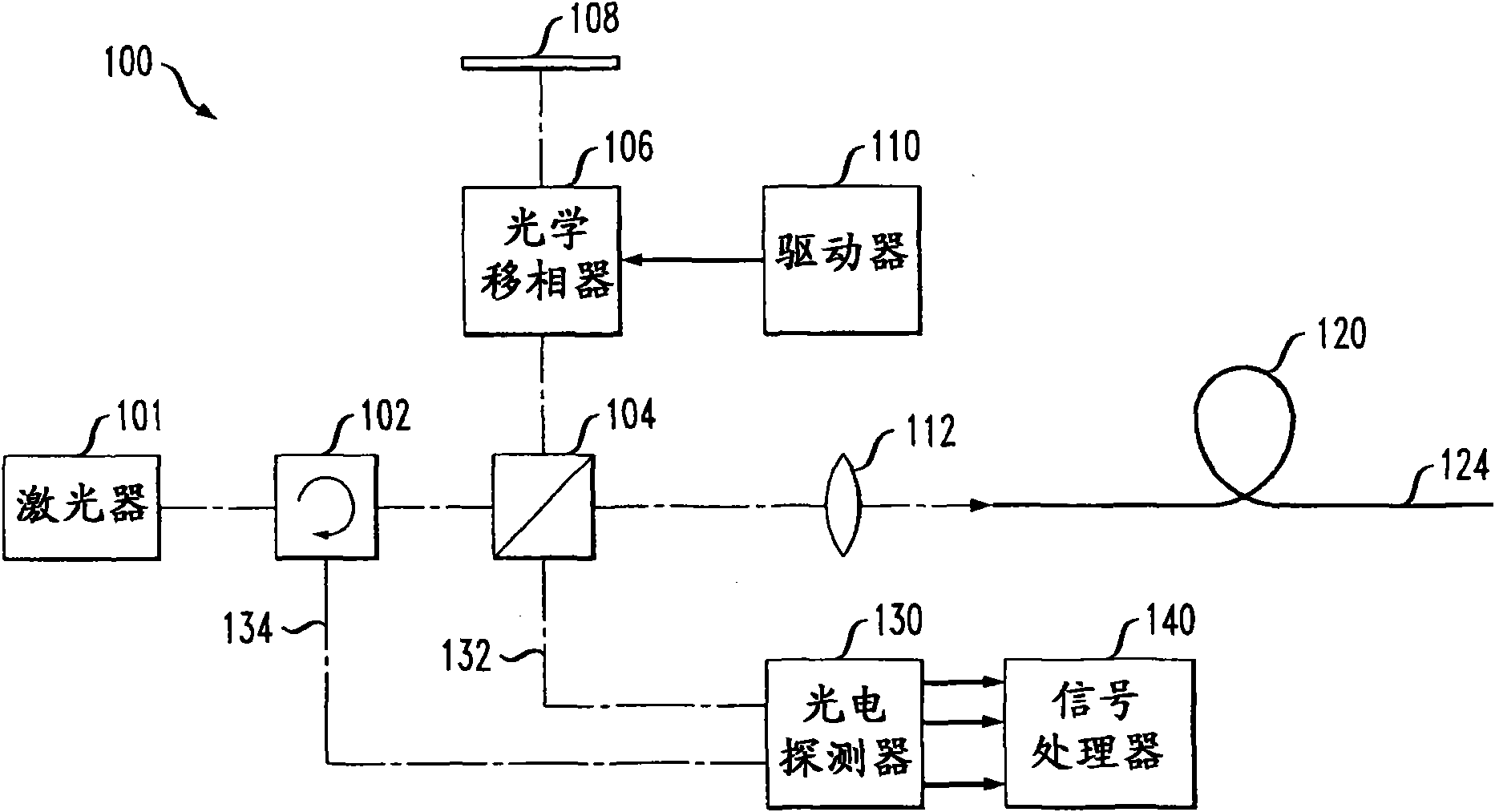

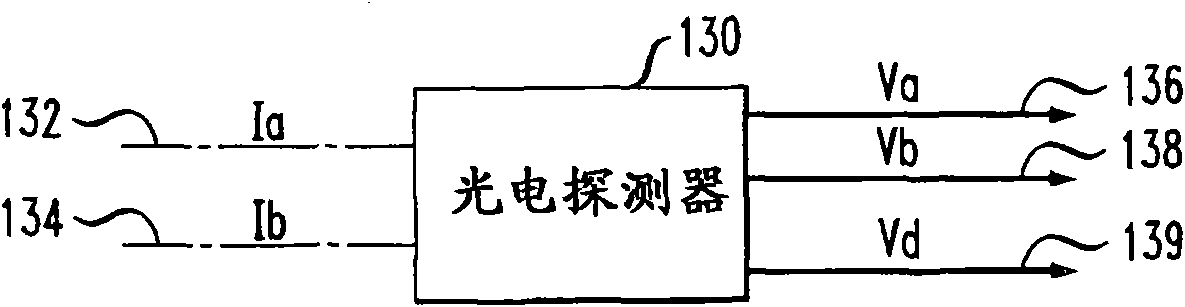

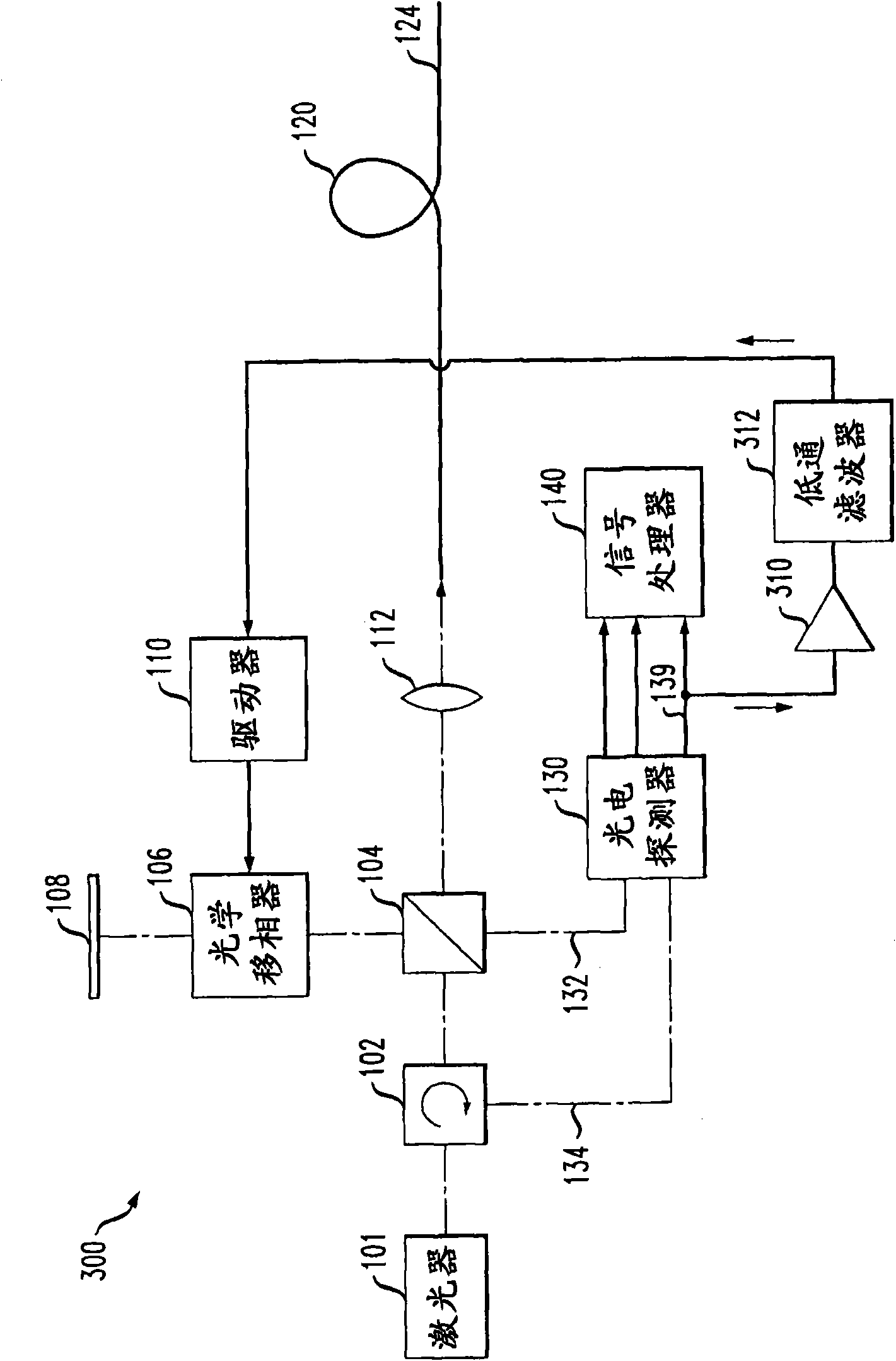

[0020] figure 1 A schematic diagram of one embodiment of an ultrasonic pressure sensor 100 constructed in accordance with the principles of the present invention is shown. The ultrasonic pressure sensor 100 employs a Michelson interferometer structure. Laser light from laser 101 passes through optical circulator 102 , beam splitter 104 and focusing lens 112 and is coupled into optical fiber 120 . Optical fiber 120 acts as a probe for ultrasonic pressure sensor 100 ; for this reason, optical fiber 120 is referred to herein as probe optical fiber 120 . Beam splitter 104 also splits a portion of the laser light and directs it through optical phase shifter 106 and reflects off mirror 108 . The distal end 124 of the detection fiber 120 has a reflective coating at its tip such that laser light reaching the distal end 124 is substantially reflected back. The two reflected beams of light from the mirror 108 and from the fiber distal end 124 travel back and are combined in the beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com