Photoelectric conversion device for detecting sulfur

A photoelectric conversion device and a technology for measuring sulfur, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of no related devices, etc., and achieve the effects of convenient sample taking, short transmission distance, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

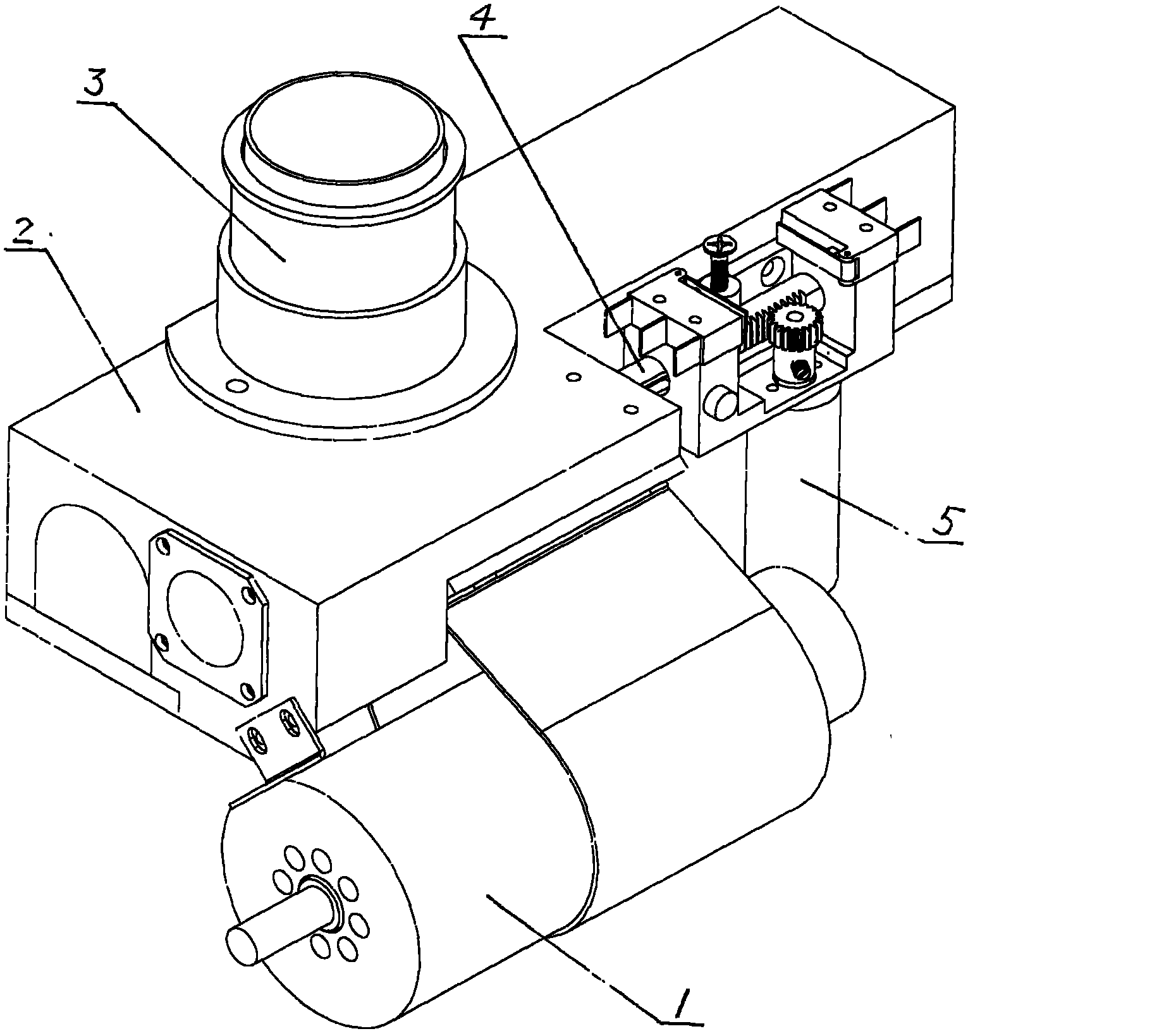

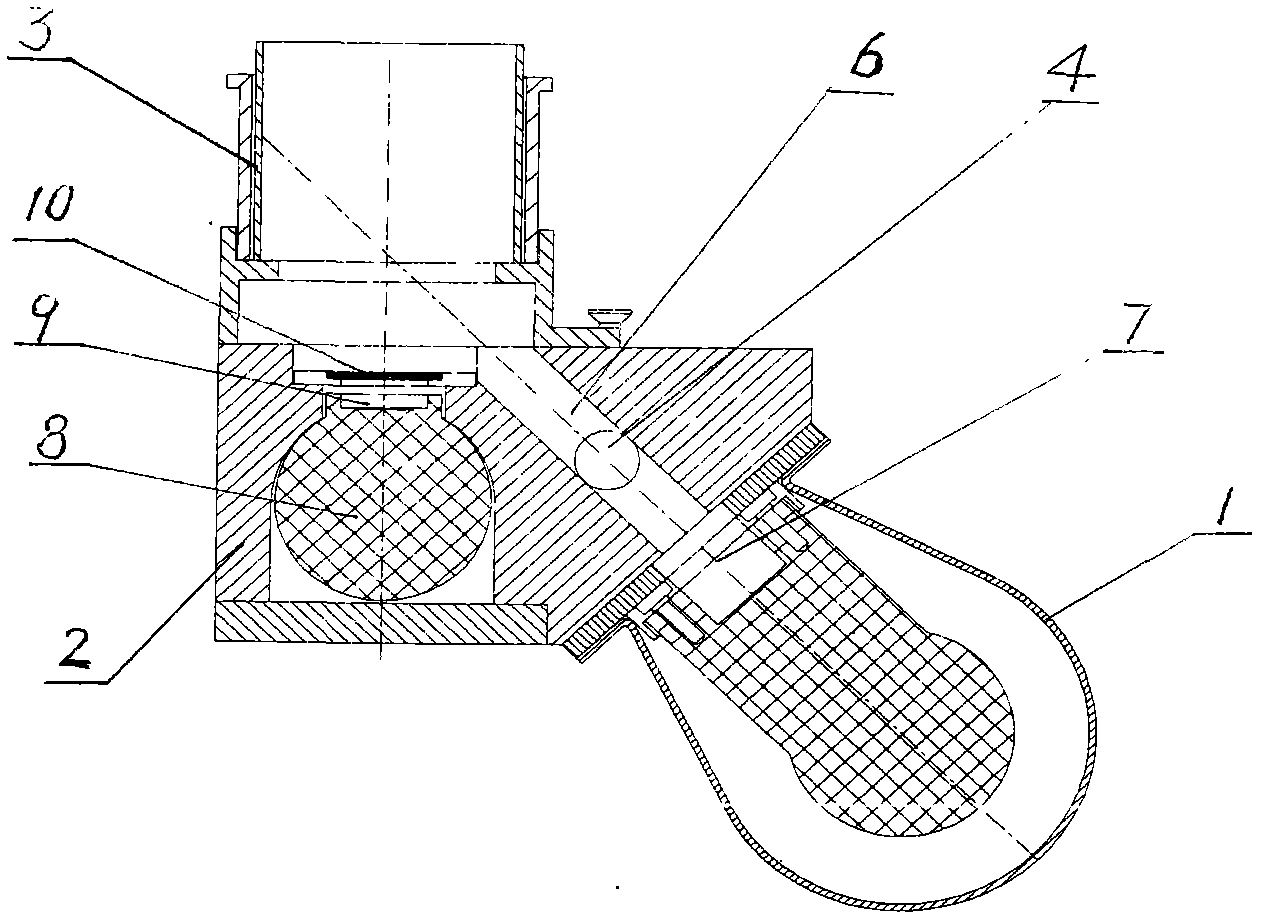

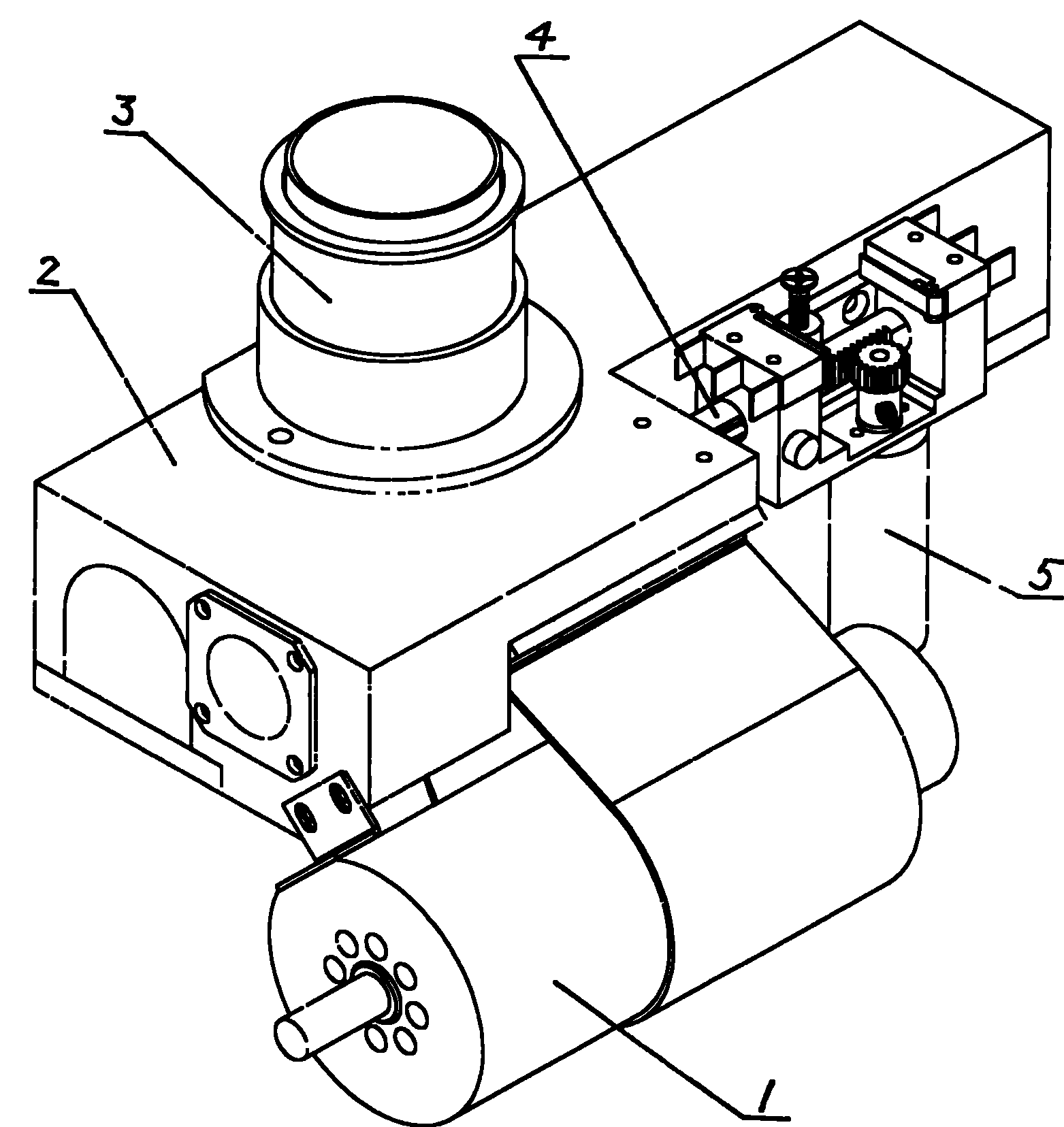

[0009] Referring to the accompanying drawings, the X-ray tube 1 is fixed on the side of the support frame 2, the collimator 7 is aligned with the oblique through hole 6 on the support frame, and the sample cup 3 arranged at the sample window at the top of the support frame is covered by the inner and outer cups. It is composed of a layer of polycarbonate film, the proportional counter 8 and the probe 9 are arranged directly under the sample cup, the axis of the probe is collinear with the axis of the sample cup, the center line of the oblique through hole intersects the axis of the probe, and the angle is 45°. In the sample cup, there is a secondary optical filter 10 between the probe and the sample window, and there is a primary optical filter at the front end of the collimator. The stop post 4 is horizontally and vertically inserted or withdrawn from the oblique through hole driven by the motor 5 and the gear-rack transmission mechanism, and the transmission mechanism is prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com