Method for detecting corrosive and harmful gas in insulating material of dry type transformer

A technology for dry-type transformers and insulating materials, which is applied in the direction of material separation, analysis of materials, preparation of test samples, etc., can solve the problem that standards cannot be realized, and there is no method for detecting corrosive and harmful gases in dry-type transformer insulation materials, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

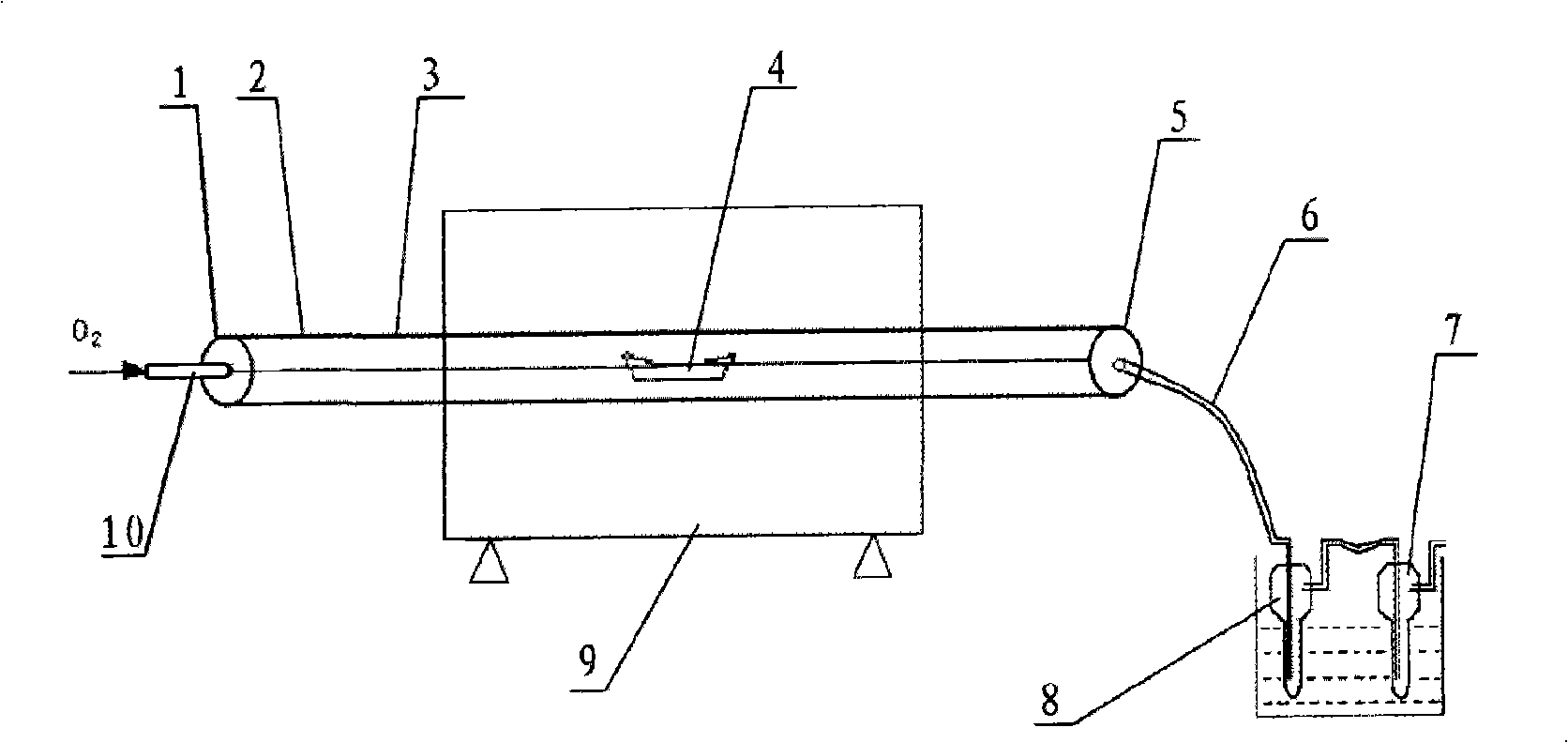

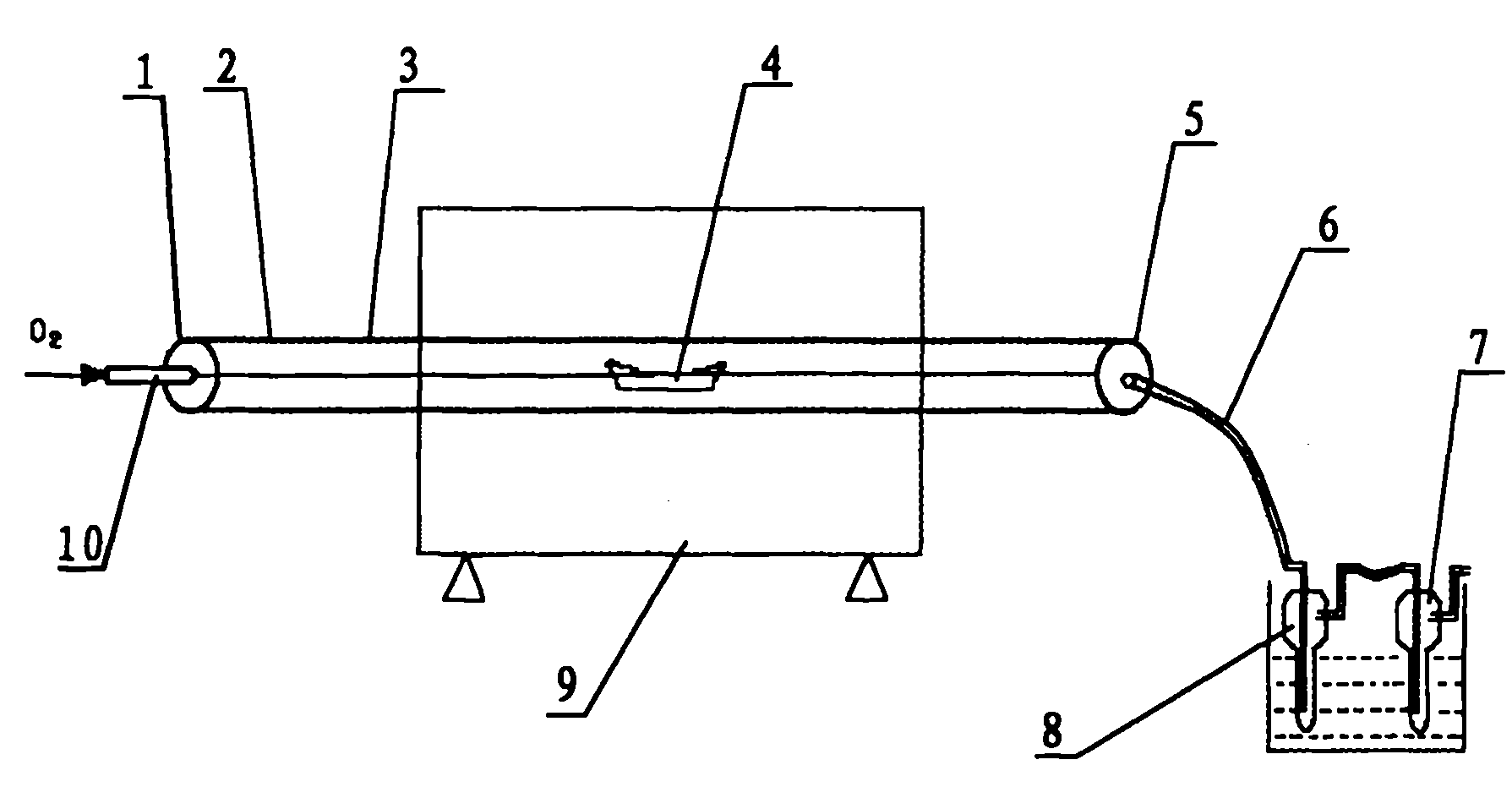

[0015] (1), extract the insulating material sample from the winding of the tested product, take 0.300 g after crushing and put it into the sample boat 4;

[0016] (2), sample boat is put into 9 quartz tubes 3 lis of tubular resistance furnace;

[0017] (3), the method that the air inlet of quartz tube 2 is connected with oxygen bottle, and the air outlet is connected with two inspiratory bottles connected in series is that an end cover 1,5 is respectively arranged at the two ends of quartz tube 2, and each end cover is inserted Breather pipe 10,6 makes the quartz tube airtight, prepares to be filled with oxygen, and the method for connecting two suction bottles is that the suction port of the previous suction bottle 8 is connected to the trachea 6, and the gas outlet of the previous suction bottle 8 is connected to the rear The air inlet of an aspirating bottle 7, each aspirating bottle is filled with 4ml alkaline solution;

[0018] (4) Inflate oxygen into the quartz tube, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com