Control system and control method for steel tube length measuring, weighing and code spraying equipment

A technology of control system and steel pipe, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of inconvenient realization of real-time line printing function, inconvenient development, inaccessible people, etc., to achieve flexible and diverse report styles and reduce work The effect of reducing the amount and repetitive work and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

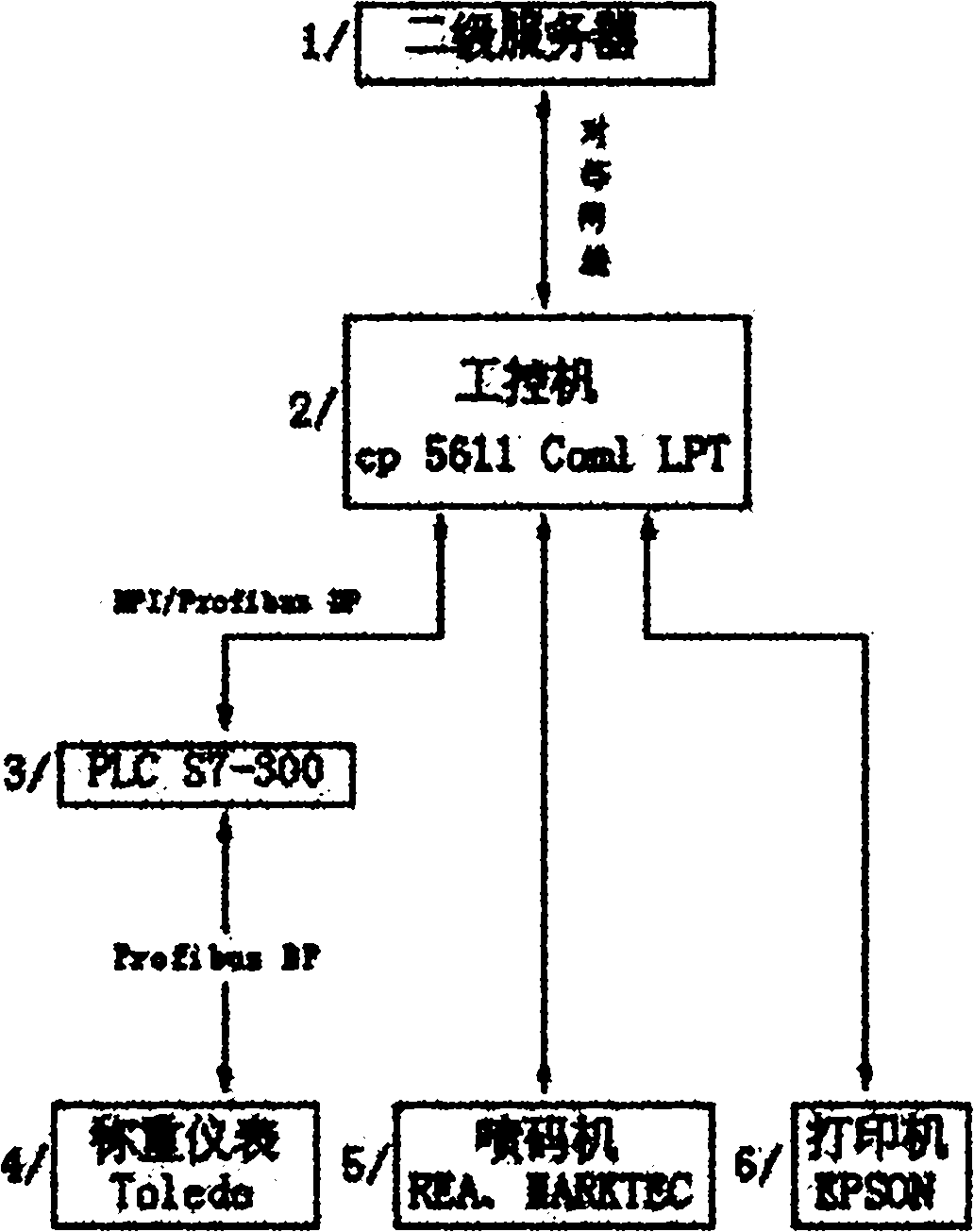

[0036] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, a control system for steel pipe length measurement, weighing, and coding equipment includes a secondary server 1, an industrial computer 2, a programmable logic controller PLC 3, a weighing instrument 4, an inkjet printer 5, and a printer 6. The industrial control The machine 2 is connected with the inkjet printer 5 and the printer 6 respectively through the serial port and the parallel port, and is connected with the secondary server 1 through the peer-to-peer network cable at the same time, and the industrial computer 2 is connected with the programmable controller PLC3 through the Profibus DP bus mode, which can be The programming controller PLC3 communicates with the weighing instrument 4 through the Profibus DP bus mode. The industrial computer 2 is the industrial computer 2 installed with the control software of the steel pipe length mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com