Electrolyte of lithium ion battery adopting natural graphite as negative material

A technology for lithium-ion batteries and negative electrode materials, which is applied in secondary batteries, circuits, electrical components, etc., can solve problems affecting electrolyte performance and side reactions, and achieve the effect of reducing intercalation and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

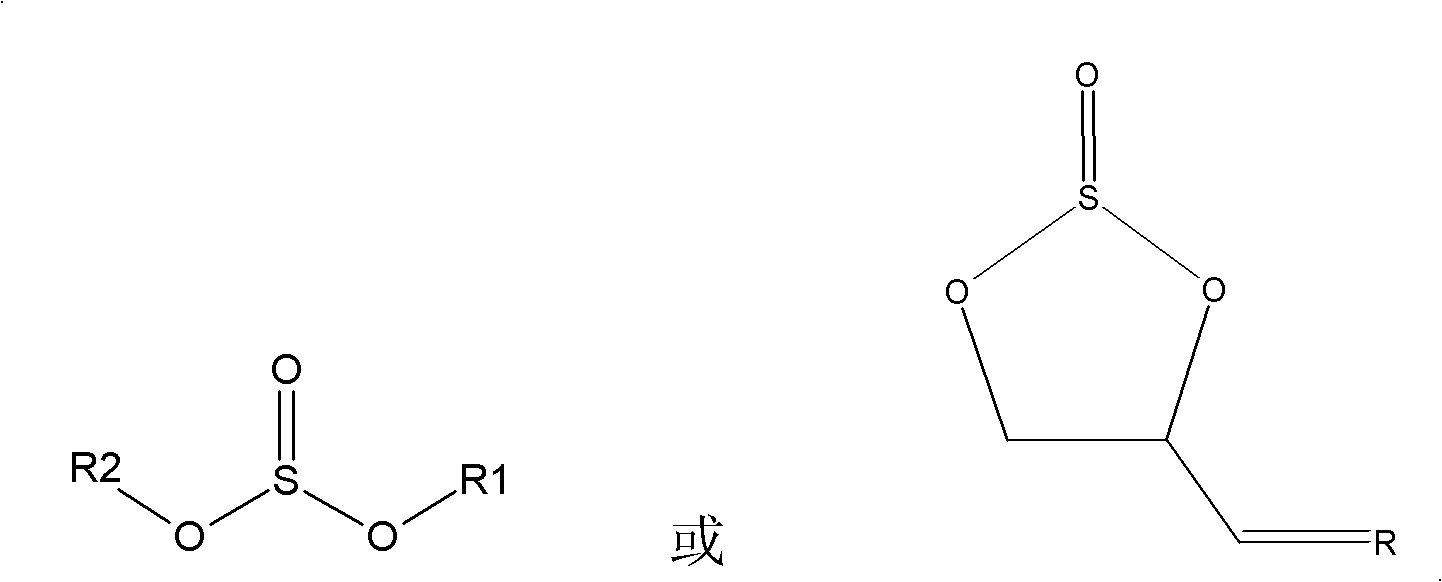

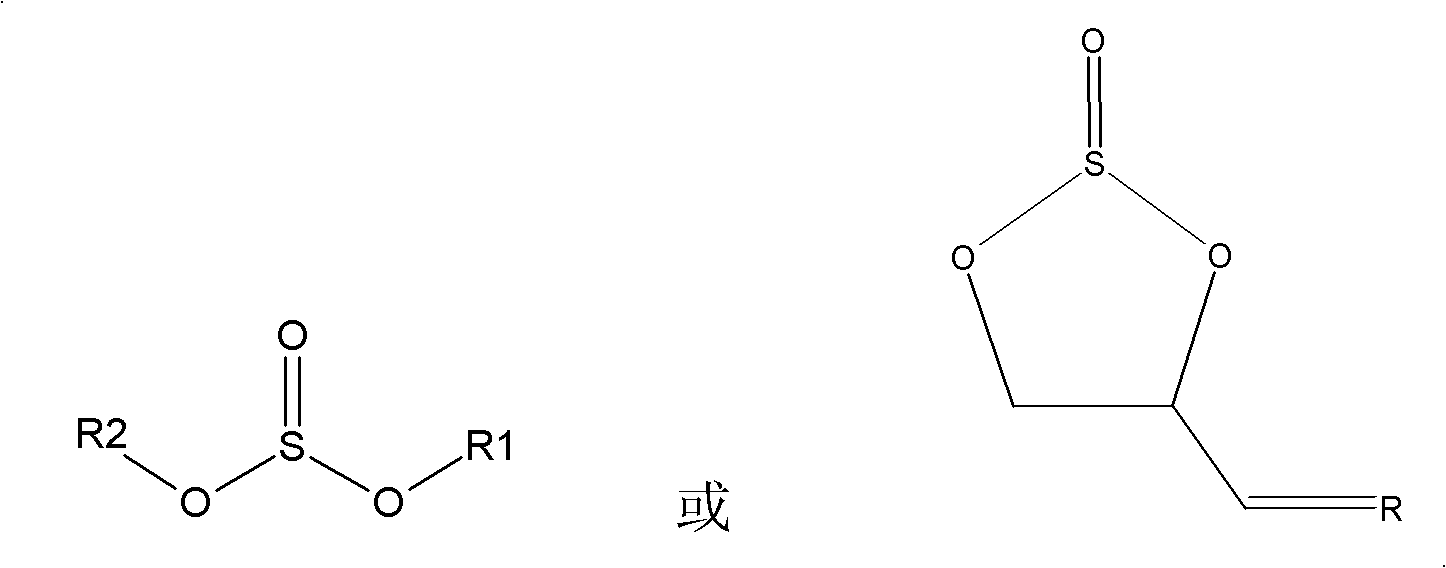

Method used

Image

Examples

Embodiment 1

[0025] in an argon-filled glove box (H 2 (0<10ppm), each organic solvent is configured in the following proportions. Ethyl acetate (EC) / dimethyl carbonate (DMC) / ethyl methyl carbonate (EMC)=1:1:1 (wt%). The solvent accounts for 84.5% of the total weight of the electrolyte.

[0026] The lithium salt is lithium hexafluorophosphate (LiPF6), its concentration is 1 mole, and the solute accounts for 12.5% of the total weight.

[0027] The addition of additive VC (vinylene carbonate) is 1%, the addition of additive FEC (fluoroethylene carbonate) is 1%, the additive dimethyl sulfite ((CH 3 ) 2 SO 3 ) in an amount of 1%. Add in order according to the above amounts, and fully stir evenly to obtain the lithium-ion battery electrolyte of the present invention.

Embodiment 2

[0029] in an argon-filled glove box (H 2 (0<10ppm), each organic solvent is configured in the following proportions. Ethyl acetate (EC) / dimethyl carbonate (DMC) / ethyl methyl carbonate (EMC)=1:1:1 (wt%). The solvent accounts for 84.5% of the total weight of the electrolyte.

[0030] The lithium salt is lithium hexafluorophosphate (LiPF 6 ), its concentration is 1 mole, and the solute accounts for 12.5% of the total weight.

[0031] The addition amount of additive VEC (vinyl ethylene carbonate) is 1%, the addition amount of additive FEC (fluoroethylene carbonate) is 1%, the additive ethyl methanesulfonate (CH 3 CH 2 SO 3 CH 3 ) in an amount of 1%. Add in order according to the above amounts, and fully stir evenly to obtain the lithium-ion battery electrolyte of the present invention.

Embodiment 3

[0033] in an argon-filled glove box (H 2 (0<10ppm), each organic solvent is configured in the following proportions. Ethyl acetate (EC) / dimethyl carbonate (DMC) / ethyl methyl carbonate (EMC)=1:1:1 (wt%). The solvent accounts for 84.5% of the total weight of the electrolyte.

[0034] The lithium salt is lithium hexafluorophosphate (LiPF 6 ), its concentration is 1 mole, and the solute accounts for 12.5% of the total weight.

[0035] The addition of additive VEC (vinyl ethylene carbonate) is 1%, the addition of additive FB (fluorobenzene) is 1%, the additive vinyl vinyl sulfite (C 4 h 6 SO 3 ) in an amount of 1%. Add in order according to the above amounts, and fully stir evenly to obtain the lithium-ion battery electrolyte of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com