Heat sink cooling method for series sector radial microchannel crystals of solid laser

A technology of solid-state lasers and cooling methods, which is applied to lasers, laser components, phonon exciters, etc., and can solve problems such as laser performance degradation, thermal damage, and high heat consumption density of crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

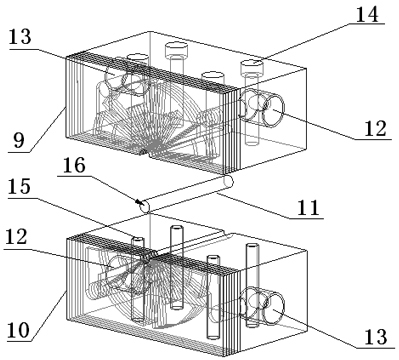

[0023] Such as figure 1 As shown, it includes a laser crystal rod 11 and an upper metal block heat sink 7 and a lower metal block heat sink 8 for clamping the laser crystal rod 11. There is a fan-shaped radiation microchannel around the pumping end face 16 of the laser crystal rod 11, and the fan-shaped radiation microchannel It consists of an upper serial fan-shaped radial microchannel layer 9 and a lower serial fan-shaped radial microchannel layer 10 . The upper series fan-shaped radial microchannel layer 9 is welded together with the upper metal block heat sink 7 to form an upper heat sink, and the lower series fan-shaped radial microchannel layer 10 is welded together with the lower metal block heat sink 8 to form a lower heat sink. The upper heat sink assembly hole 14 and the lower heat sink assembly hole 15 can be connected by screws, so that the upper and lower heat sinks clamp the laser crystal rod 11 . The water inlet 12 and the water outlet 13 of the upper metal bl...

Embodiment 2

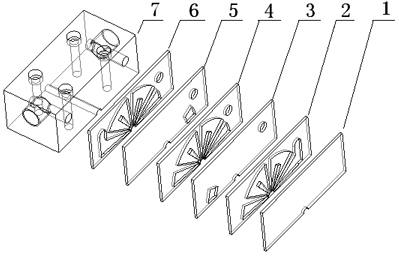

[0033] In the present invention, metal sheets and water-proof sheets can be stacked in 2 groups, that is, the laminated metal sheets in the upper series fan-shaped radial microchannel layer 9 and the lower series fan-shaped radial microchannel layer 10 are in 2 sheets, water-proof 2 slices. The front-end sealing metal sheet 1, the first fan-shaped radial microchannel metal sheet 2, the first partition metal sheet 3, and the second fan-shaped radial microchannel metal sheet 4 are welded together in position, and a 0.1mm thick solder film is added. Between the parts, both ends are clamped with force from a flat mold and placed in a vacuum furnace. When the temperature of the vacuum furnace reaches above 778°C, the solder layer melts and infiltrates evenly between the parts, so that each part The components are firmly welded together to form radial microchannels. It is also possible to use the silver layer as the solder, first plate silver on the surface of the machined parts 1~...

Embodiment 3

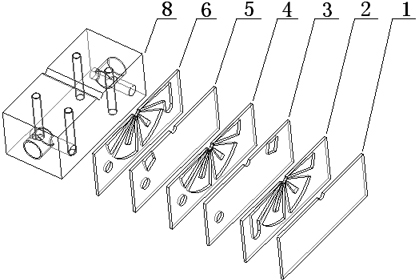

[0035] In the present invention, the lamination of metal sheets and water-proof sheets can be selected from 4 groups, that is, the laminated metal sheets in the upper series fan-shaped radial microchannel layer 9 and the lower series fan-shaped radial microchannel layer 10 are in 4 sheets, water-proof 4 slices. The total thickness of the stack is not less than 2mm, and the maximum is 6mm. The upper serial fan-shaped radial microchannel layer 9 or the lower serial fan-shaped radial microchannel layer 10 and the fixed fabrication of the metal block heat sink, including machining and welding procedures, are the same as those in Embodiment 1 and Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com