Method for setting overcurrent protection point for insulated gate bipolar transistor

A bipolar transistor, overcurrent protection point technology, applied in emergency protection circuit devices, electrical components, etc., can solve the problems of inaccurate overcurrent judgment, no consideration of junction temperature factors, etc. Protect the effect of fast action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

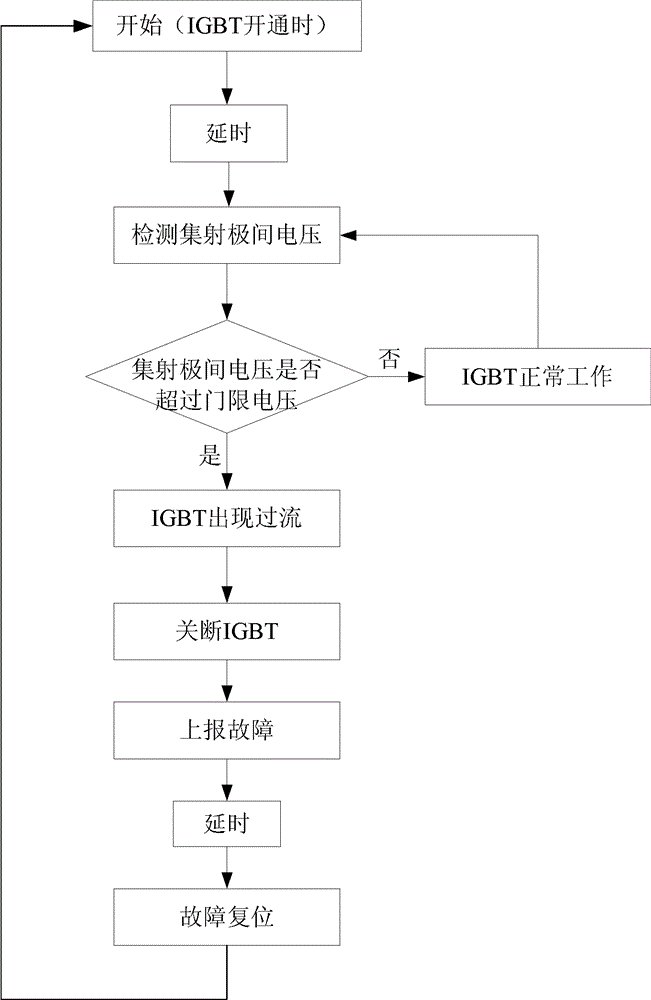

[0038] The setting method of the overcurrent protection point in the present invention is a setting method based on the driver, and the flow chart of the overcurrent detection and protection of the driver is shown in the attached figure 1 shown. A dynamic V on the driver ce After the voltage detection circuit is powered on, it starts to detect V ce Voltage, judge the size between the voltage Vce between the collector and the emitter and the threshold voltage, if the voltage Vce between the collector and the emitter is less than the threshold voltage, it means that the IGBT is in a normal working state; if the voltage Vce between the collector and the emitter exceeds the threshold Voltage, it can be judged that the IGBT is over-current, the driver reports back to the controller through the optical fiber, the controller sends a blocking signal, and the IGBT is turned off, so as to achieve the purpose of over-current protection.

Embodiment 2

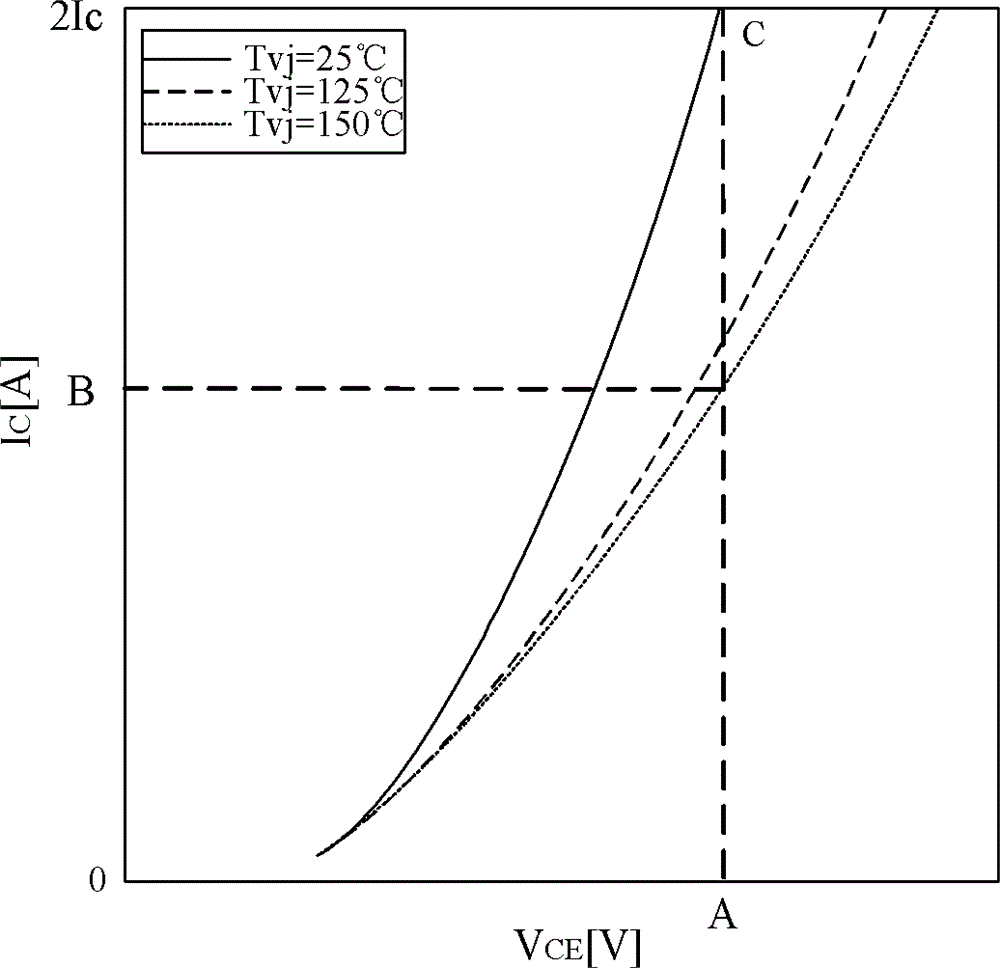

[0040] In the present invention, according to the manufacturing process of the IGBT, it has been proved through many experiments that when the collector current I of the IGBT c When it is within 2 times the rated current, it is safe to turn off; when the collector current I of the IGBT c In the range of 2 times to 4 times the rated current, there is a risk of tube explosion when shutting off; when the collector current I of the IGBT c It is also safe to shut down when the rated current exceeds 4 times. Therefore, when setting the over-current protection, the shutdown current of the IGBT should be within 2 times the rated current at different junction temperatures to ensure the safety of the IGBT.

[0041] IGBT V at different junction temperatures ce Voltage vs. Collector Current I c The relationship curve is attached figure 2 As shown, it can be seen that at different junction temperatures, Vce with I c The correspondence is different, but V ce with I c The proportiona...

Embodiment 3

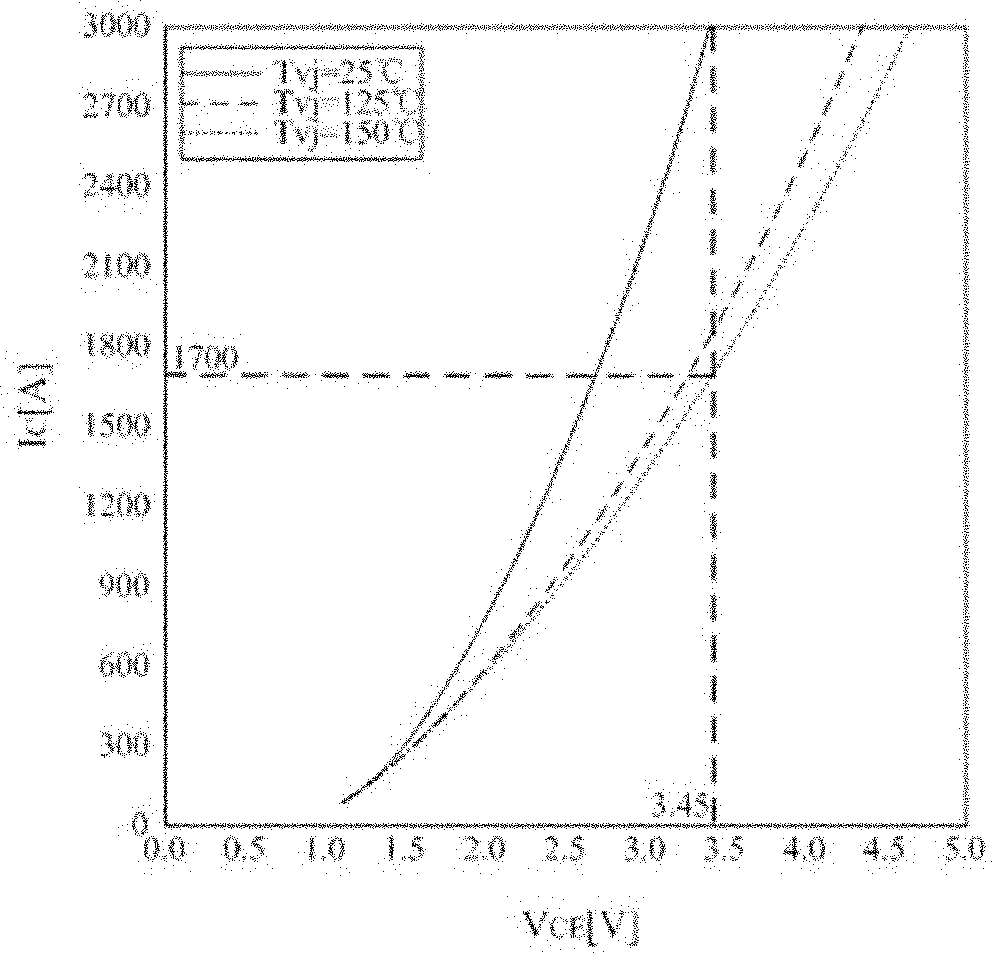

[0043] Taking two 3300V / 1500AIGBTs connected in parallel, the effective value of the rated working current of the device is 950A, and the maximum overload is 1.4 times as an example for analysis. The adopted driver is a master-slave driver, and the master-slave driver is connected through a parallel data line to respectively control the IGBTs used in parallel.

[0044] as attached image 3 As shown, the curve in the figure is the relationship curve between Vce and Ic of the IGBT device, the abscissa represents the conduction tube voltage drop Vce, and the ordinate represents the collector current Ic. The three curves in the figure represent the relationship between Vce and Ic when the junction temperature of the IGBT is 25°C, 125°C and 150°C respectively. It can be seen that as the current increases, the voltage drop of the conduction tube also gradually increases, and Vce It is basically proportional to Ic. The setting method of the overcurrent protection point is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com