Feeding system for ship unloader and control method thereof

A technology of feeding system and ship unloader, which is applied in loading/unloading, transportation and packaging, etc. It can solve the problems of material accumulation and spilling in the drop pipe, and achieve the effects of strong flexibility, environmental pollution reduction and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

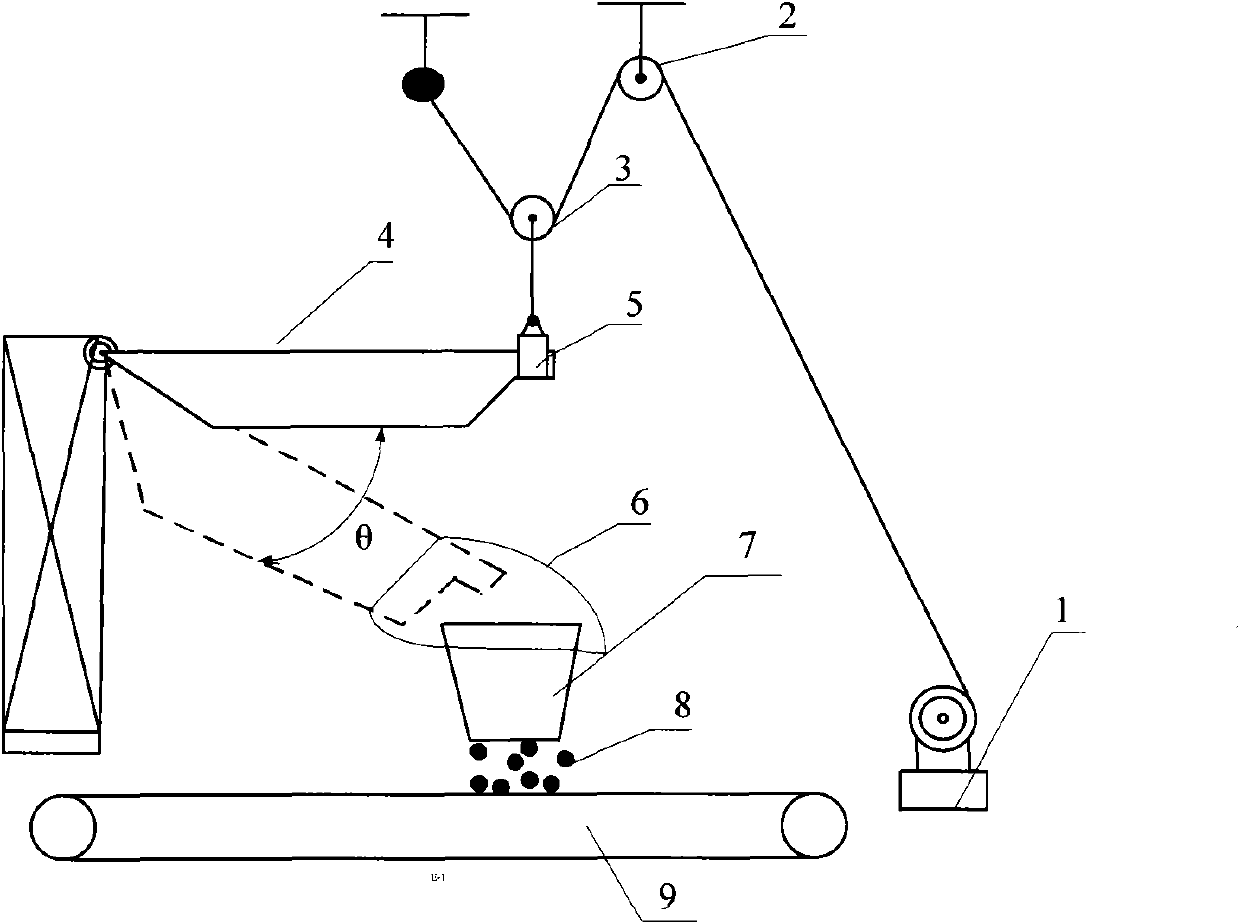

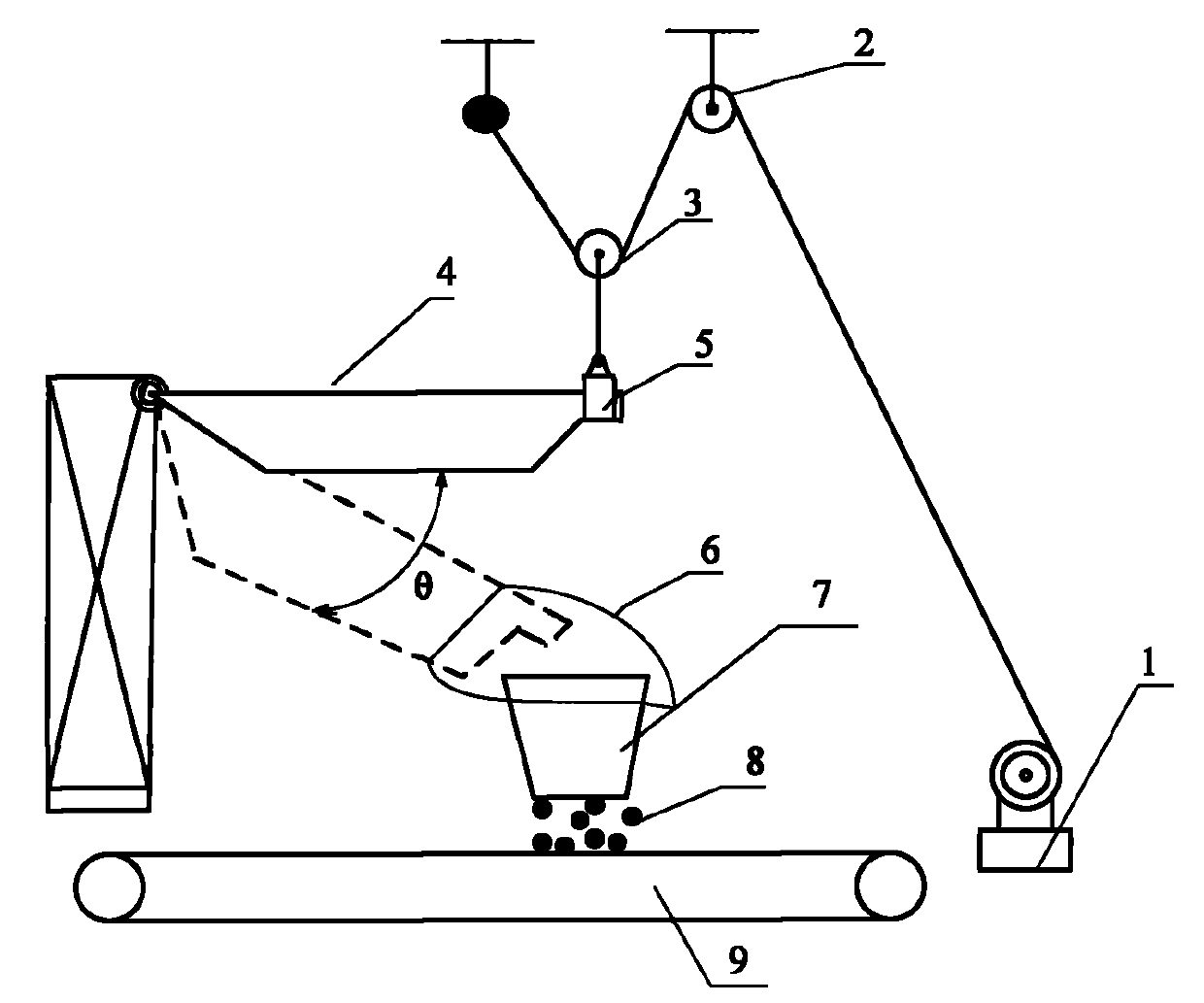

[0017] like figure 1 As shown, the feeding system of the present invention includes: a winch 1, a pulley fixing device, a feeder and a flexible dust-proof joint.

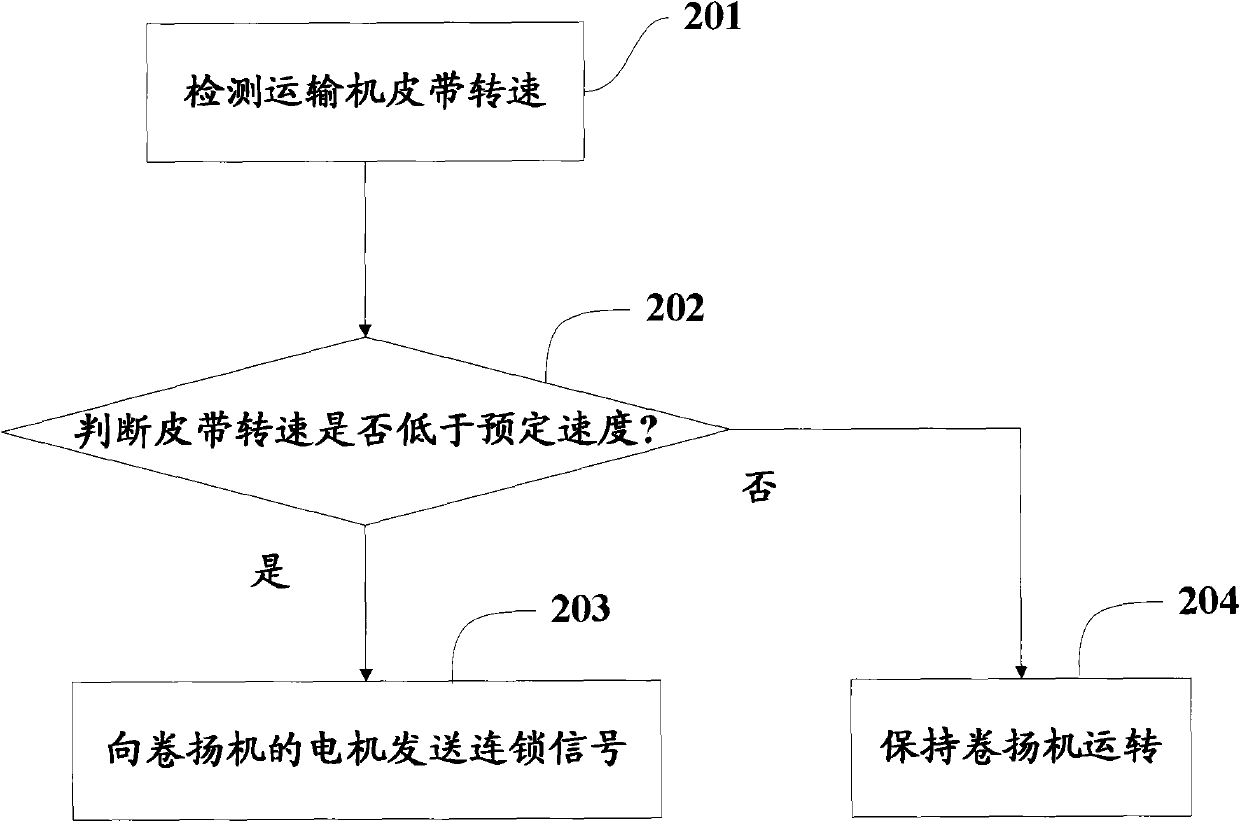

[0018] The hoist is a power device used to lift loads. The hoist 1 is driven by a motor. Driven by the motor, the wire rope on the hoist is wound or loosened. The wire rope is connected to the pulley fixing device. The hoist 1 or its drive Parameters such as the output power, output torque, and wire rope length of the motor can be selected and calculated according to the actual application. The winch 1 includes a conveyor detection module and a chain control module. The conveyor detection module is used to detect whether the conveyor belt is running, which can be realized by sensors and corresponding logic circuits. The sensor can be installed near the conveyor belt, and the sensor can be a photoelectric speed sensor, or other suitable sensors can be used. The logic circuit may be implemented in any circuit known...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com