Internal temperature rise on-line monitoring method of traction transformer of V/X connection

A technology for traction transformers and transformers, applied in the directions of instruments, measuring electricity, measuring devices, etc., can solve the problems of error, high price, complicated calculation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

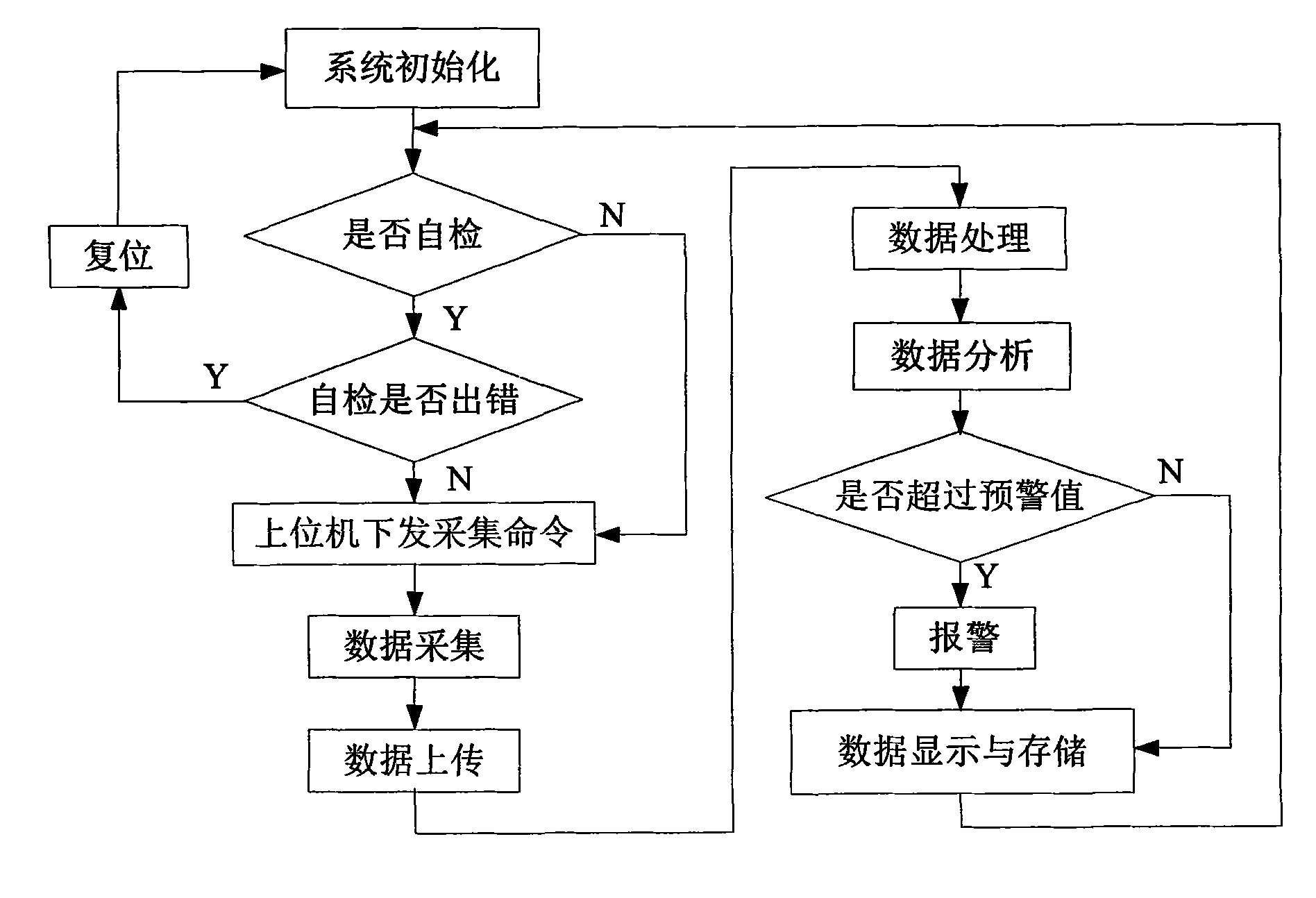

[0036] The present invention comprises following three steps, see image 3 :

[0037] The first step is to obtain the relevant parameters of the transformer, including reading the transformer rated voltage, rated current and top layer oil temperature rise under rated conditions from the transformer nameplate; obtaining the winding thermal time constant, rated temperature from the transformer temperature rise test report or factory test report or empirical formula Under the circumstances, the winding hot spot temperature rise, and input these parameters into the host computer software.

[0038] In the second step, after the system completes the initialization and self-inspection, the upper computer 4 sends communication commands according to the set monitoring time interval, and uses the top layer oil temperature monitoring module 1 installed at the thermometer seat on the top of the transformer to monitor the top layer of the V / X wiring traction transformer online Oil tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com