Light-duty gantry numerical control cutting machine

A cutting machine, gantry technology, applied in welding/cutting auxiliary equipment, large fixed members, metal processing machinery parts, etc., can solve the problem that the cutting quality and cutting accuracy cannot meet the high precision and high stability standards of the gantry CNC cutting machine and other problems, to achieve the effect of outstanding improvement effect, flexible handling and convenient handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

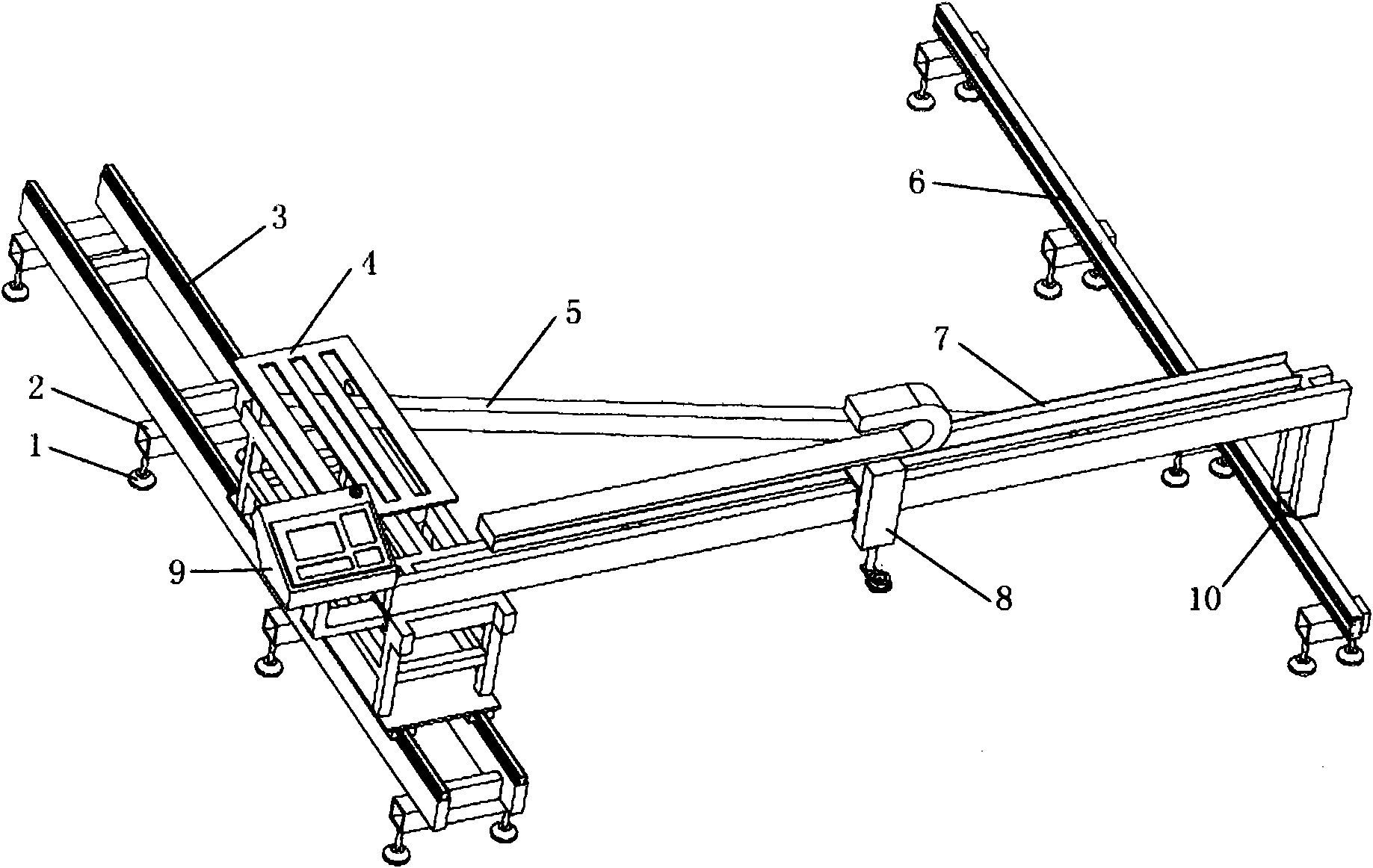

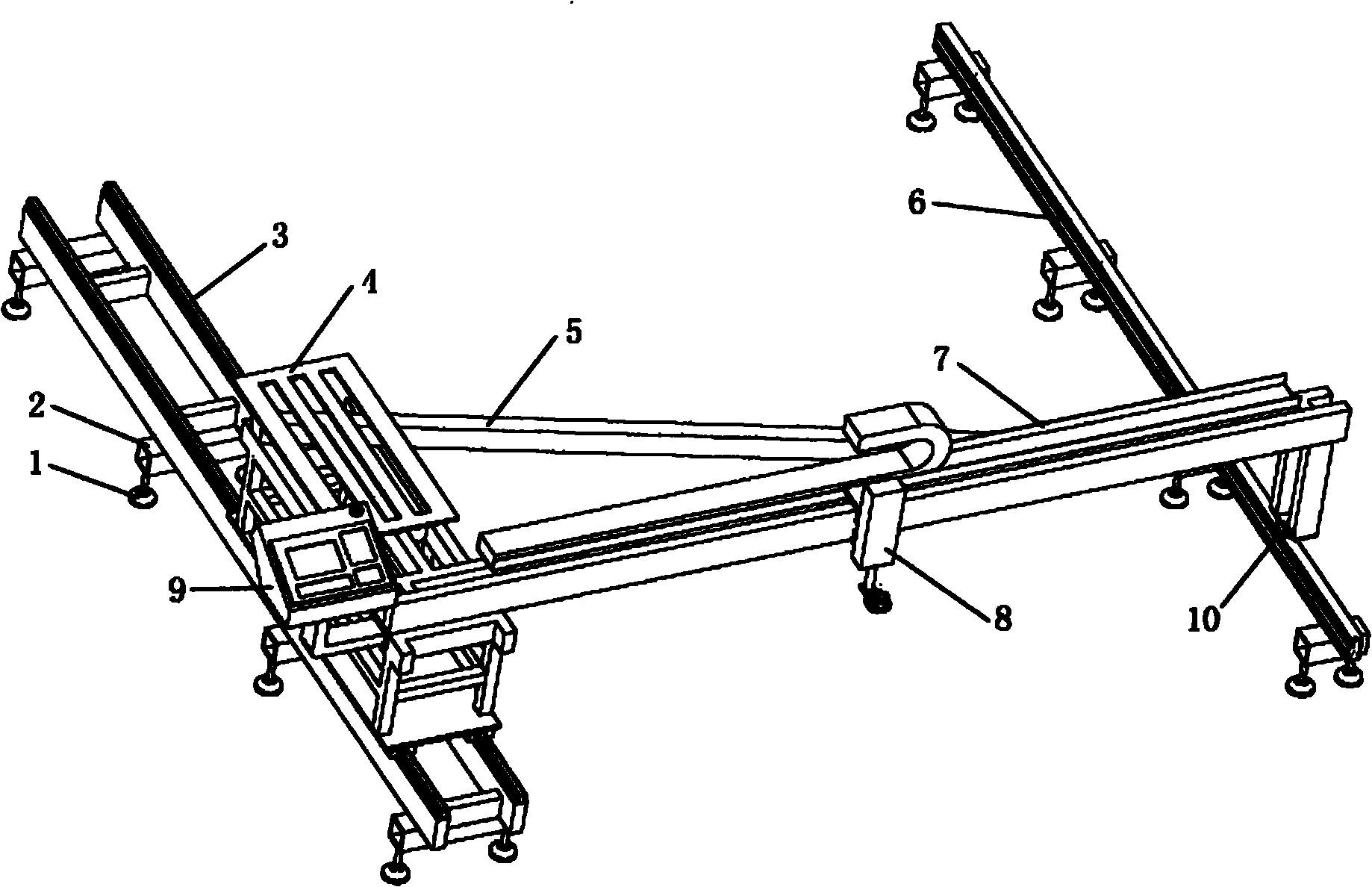

[0016] The central idea of the present invention is to use the advantages of high structural stability and good processing precision of the gantry type CNC cutting machine, combined with the advantages of flexible assembly and convenient transportation of the cantilever type CNC cutting machine, to design a lighter, more stable and more reliable , and easy disassembly and assembly of light-duty gantry CNC cutting machine to meet the ever-increasing needs of industrial production. The premise of its design is that it can be better assembled and transported while ensuring sufficient processing accuracy.

[0017] Attached below figure 1 The present invention is further described:

[0018] The structure of the light-duty gantry numerical control cutting machine of the present invention retains the structural features of the gantry type, and at the same time, improves and simplifies the structures such as the transmission guide rail and the bracket. Its structure specifically i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com