Process and device for preparing arene through low carbon hydrocarbon aromatization

A process method and aromatization technology, applied in the field of aromatization of low-carbon hydrocarbons to prepare aromatics, can solve the problems of uncontrollable reactor temperature, restrictions on the operation of the aromatization system, and short catalyst running time, so as to achieve good product quality, The effect of less carbon on the surface area and thorough reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

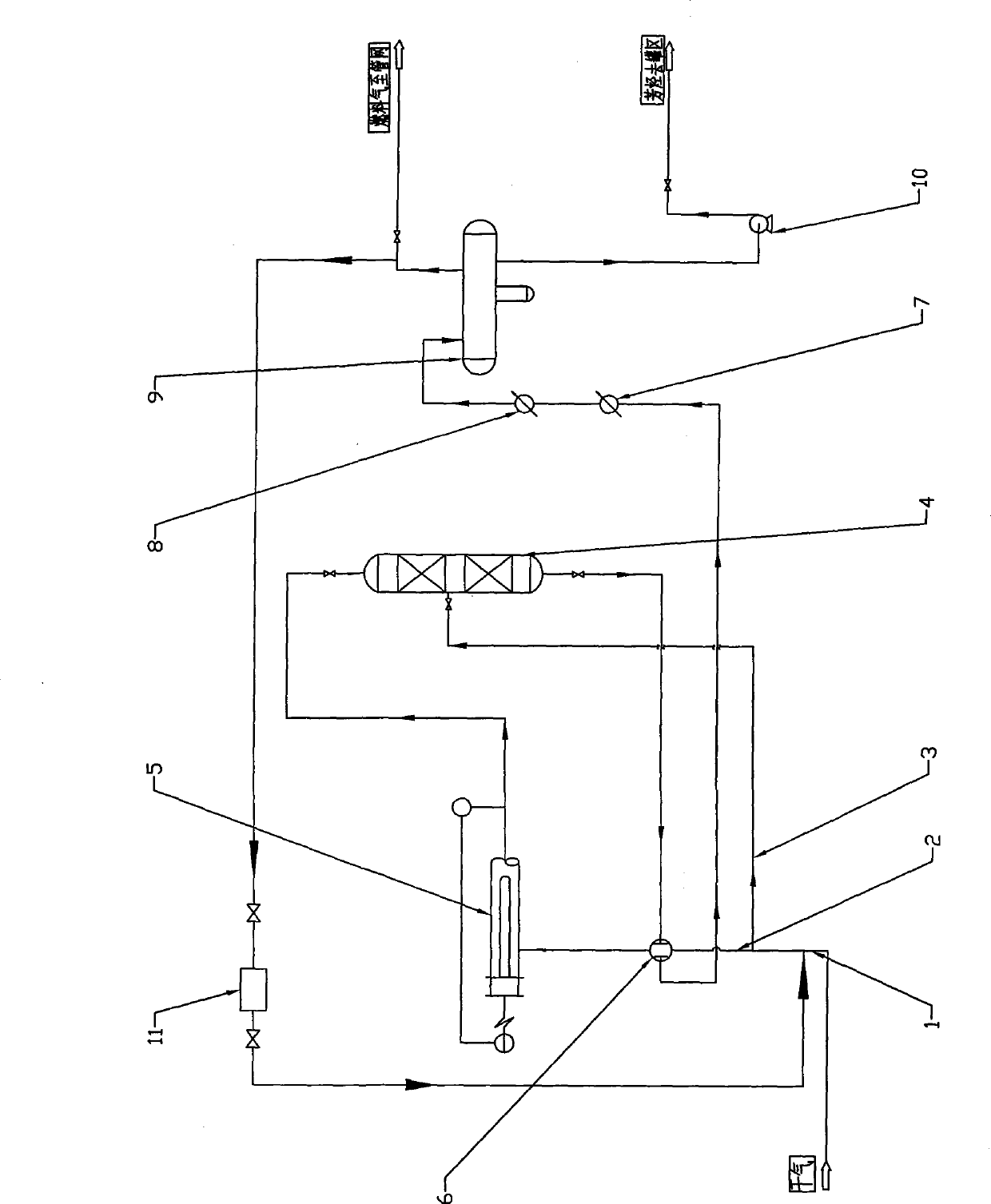

[0030] Embodiment, as shown in the figure, a process method for preparing aromatics by aromatization of low-carbon hydrocarbons, comprising the following steps: the raw material dry gas from the delivery main pipe 1 enters the first delivery branch pipe 2 and the second delivery branch pipe 3, and a part of the raw material The dry gas enters the dry gas feed heat exchanger 6 through the first delivery branch pipe 2 for heating, and then is transported to the heater 5 for further heating. After being heated to 300±50°C, it enters from the top of the aromatization reactor 4 and contacts with the catalyst Carry out aromatization reaction, another part of raw material dry gas directly enters the aromatization reactor 4 through the second delivery branch pipe 3, and contacts with the catalyst for aromatization reaction, the raw material dry gas in the first delivery branch pipe 2 and the second delivery branch pipe 3 The flow ratio of internal raw material dry gas is 3:1.

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com