Method for closed-loop power control of a road finishing machine or feeder and a road finishing machine or feeder comprising the same

A feeder and finishing machine technology, applied in road repair, transmission control, roads, etc., can solve the problems of reduced power demand, reduced internal combustion engine speed, etc., to achieve reduced resistance loss, constant power output, and maintain operation convenience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

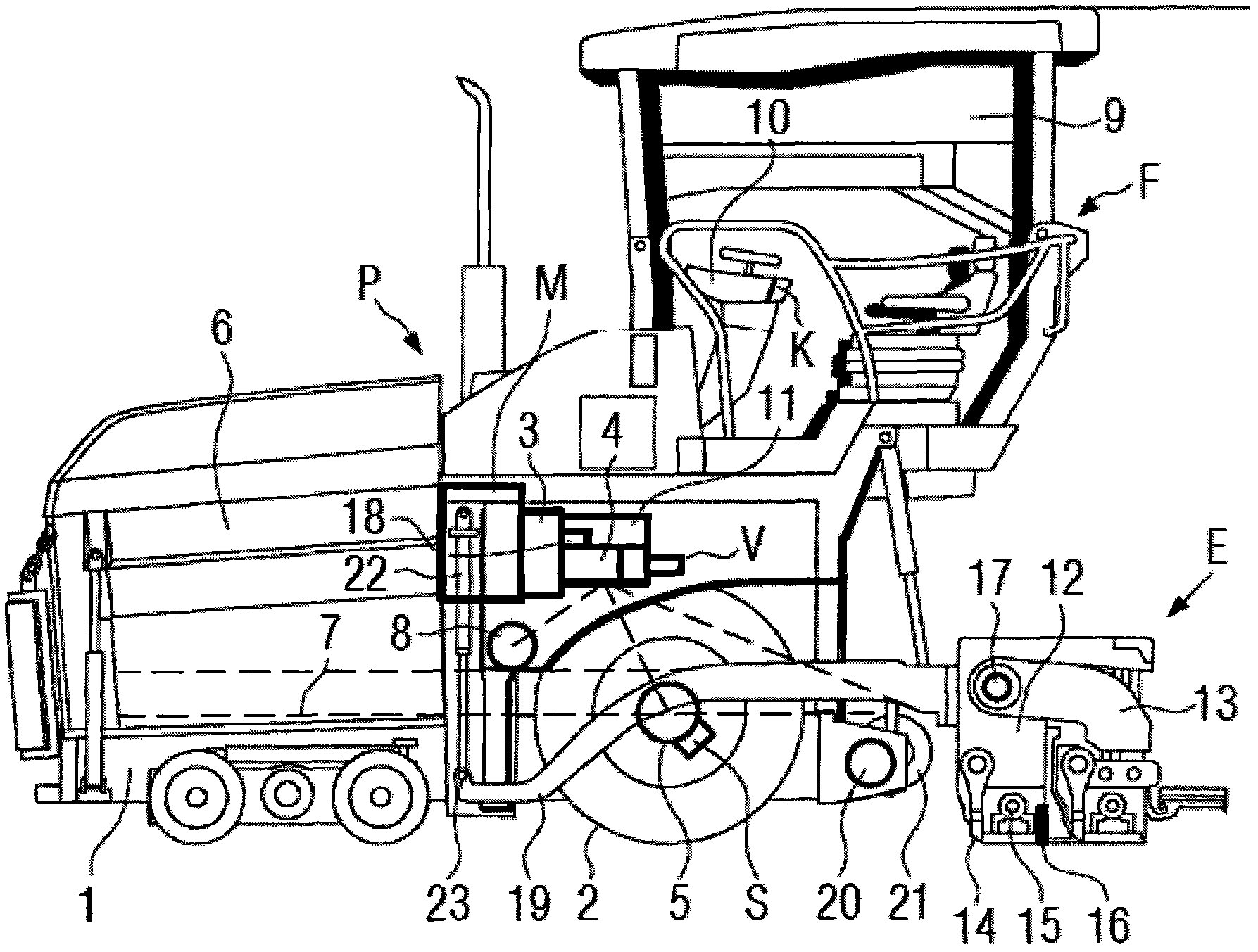

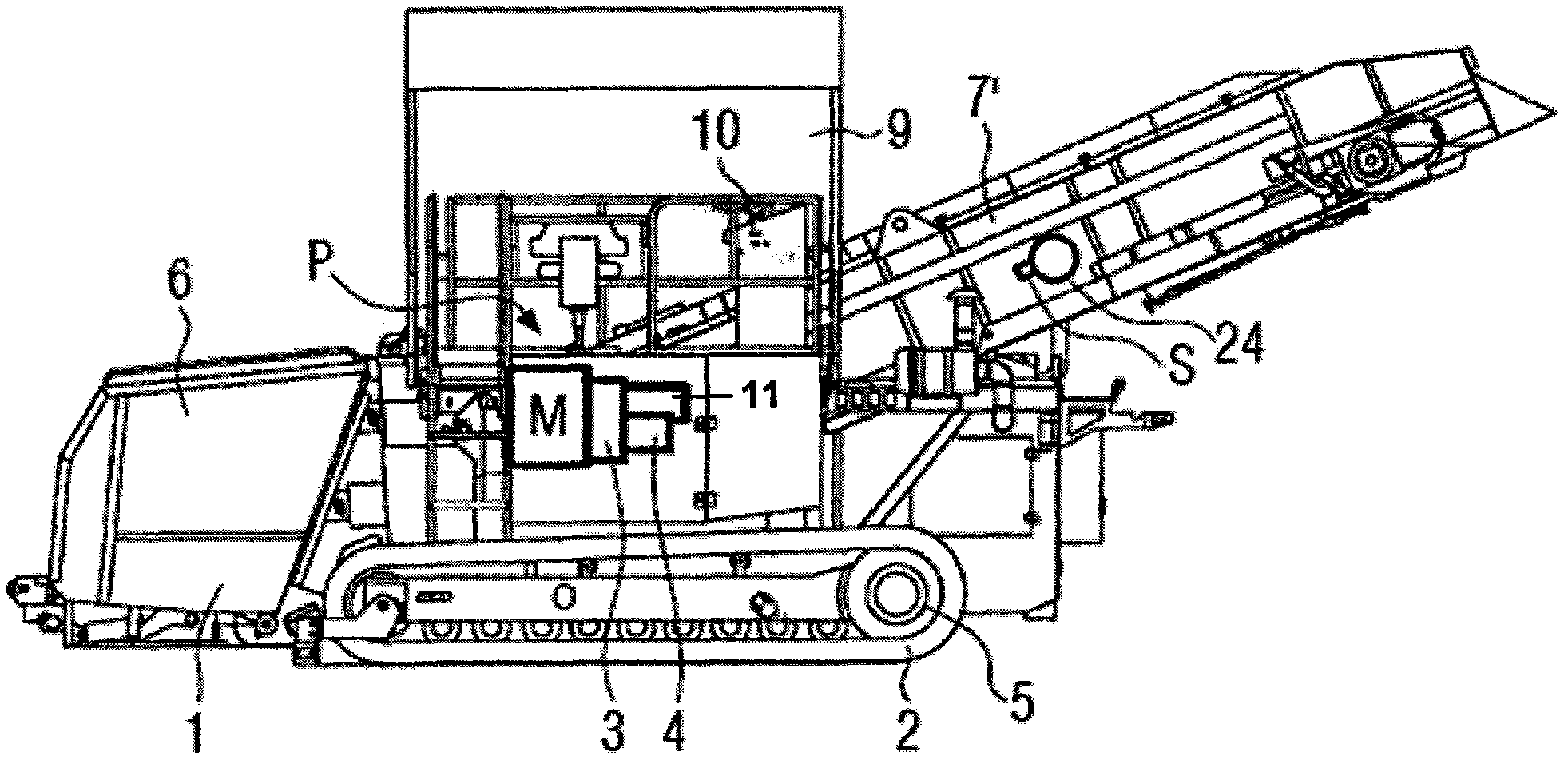

[0028] figure 1 Denotes a road finishing machine F for paving asphalt or concrete paving material for road laying. On the front side of the chassis 1 including the traveling mechanism 2 (wheel mechanism or crawler mechanism), a hopper 6 is set and a main power unit P is arranged behind it. The main power unit P includes an internal combustion engine M (usually a diesel engine), a pump transmission gear 3 and at least one variable displacement pump 4 arranged on the pump transmission gear 3 . In addition to the variable displacement pump 4 at least one further hydraulic pump 18 can also be provided. Furthermore, the generator 11 may be driven by the internal combustion engine M. As shown in FIG. On the driver's station 9 arranged on the chassis 1 there is provided, for example, a computerized control device 10 comprising a control panel K with a not shown main traction switch and other actuating and monitoring devices. At the rear of the chassis 1 , a transverse distribution...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap