Safe and efficient fully-mechanized mining method for thin coal seam under two hard conditions

A technology of thin coal seam and coal mining method, which is applied in ground mining, mining equipment, earth drilling and mining, etc., can solve the problems of high mining cost, difficult mining, and difficult mining of thin coal seams, and achieve the improvement of mine resource recovery rate, Huge social and economic benefits, the effect of reducing the hidden danger of spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. Coal mining method

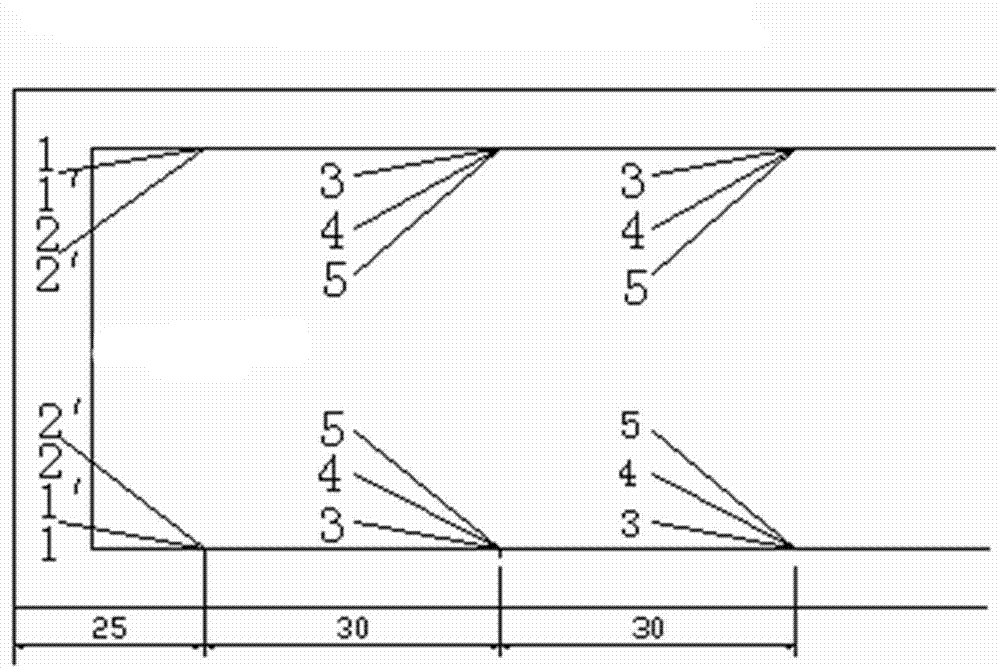

[0016] The present invention adopts the inclined long wall retreat type coal mining method, the knife feeding method adopts the end oblique cutting knife, the coal falling and coal loading of the working face are completed by a double-drum coal mining machine, and the two-way coal cutting is used when the slope is small When the slope is large, the method of cutting coal in one direction is adopted.

[0017] In order to realize the maximum production capacity target of thin coal seam mining, the present invention selects a drum shearer for comprehensive mechanized mining of thin coal seams. The thin coal seam drum shearer has the following characteristics: a) The shearer body is short, but the motor power is large; b) The fuselage is short, which can adapt to the undulation of the coal seam floor; c) It has sufficient coal and machine passing heights and walkway dimensions; d) It can cut itself; It has strong adaptability to changes in structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com