Light homogenizer and application of optical fiber panel

A technology of optical fiber panels and homogenizers, which is applied to semiconductor devices, instruments, optics, etc. of light-emitting elements, and can solve the difficulty of coupling the input end with LEDs/IREDs, and there is no homogenization plate in the near-infrared band, and small compound glasses. The lens is small and other issues, to achieve the effect of light weight, low power consumption, and easy beam shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

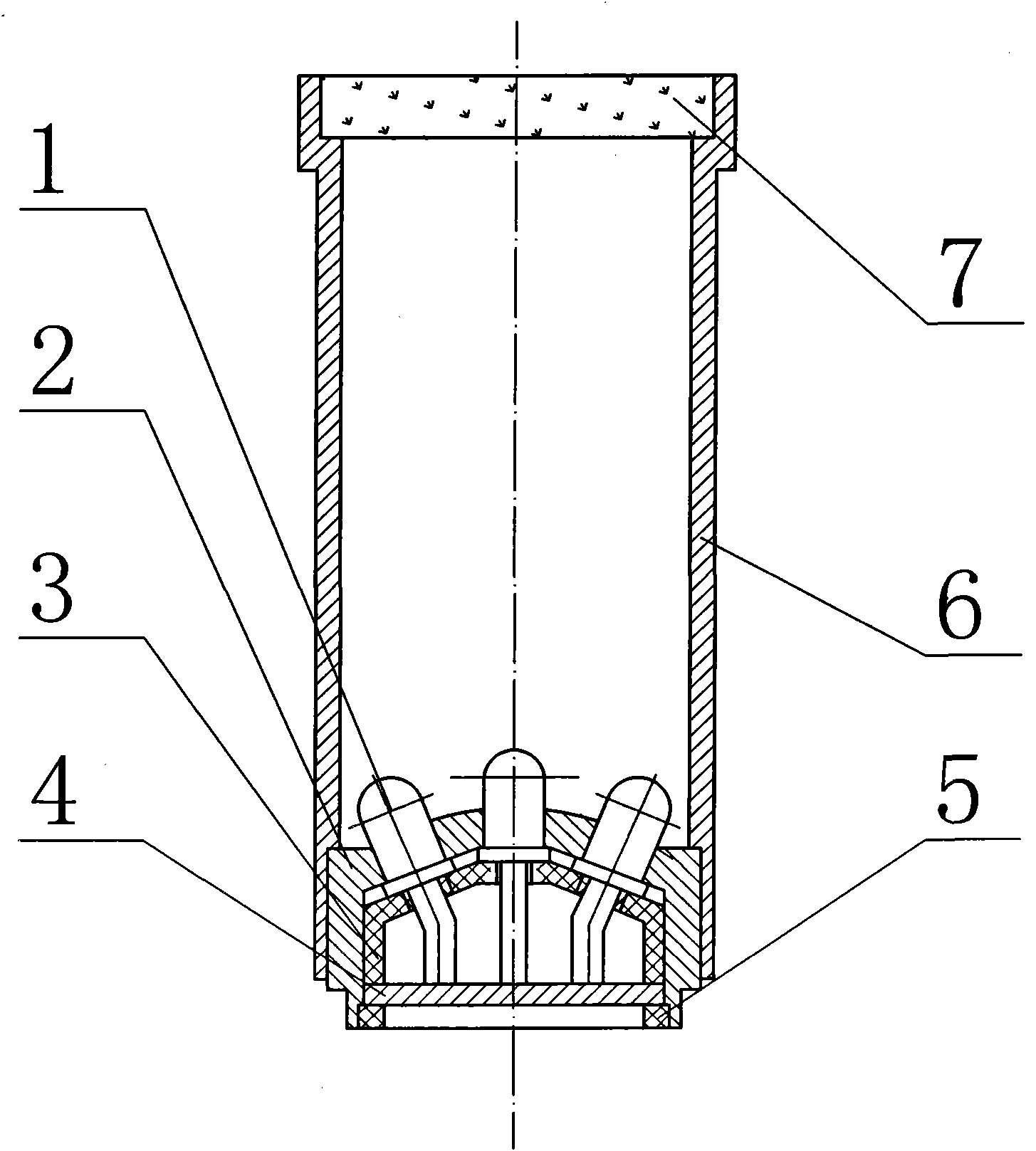

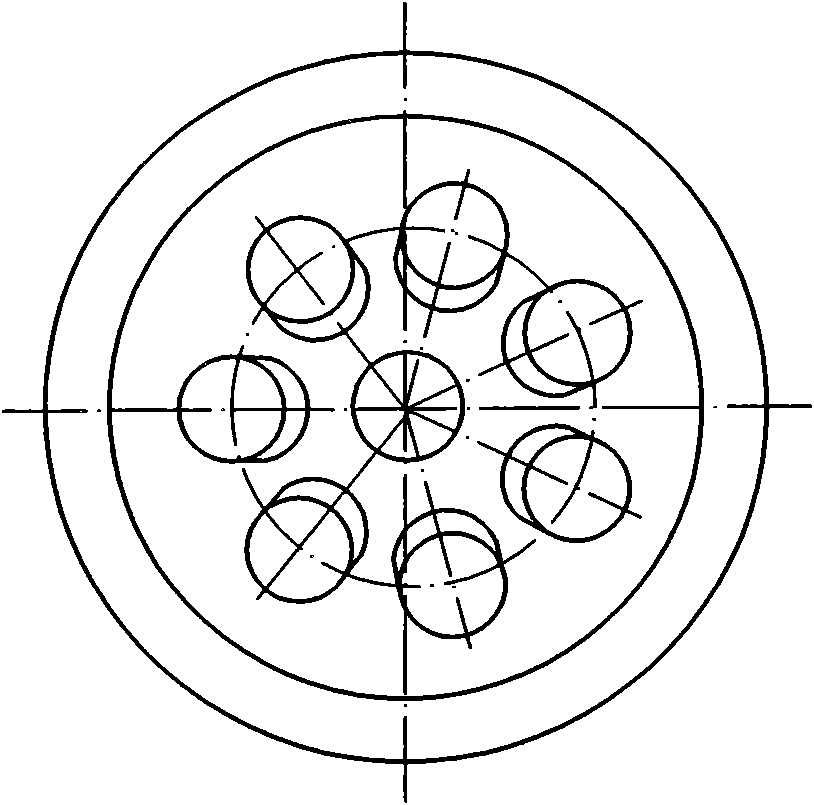

[0046] The homogenizer comprises: a cylindrical housing 6, one end of the cylindrical housing is equipped with a high-uniformity optical fiber panel 7, and the other end is equipped with a light-emitting combination, and the light-emitting combination includes a circuit board 4 and a Group light emitting device 1. The light emitting device is a light emitting diode.

[0047] A kind of This product is a special case of the application of the fiber optic panel in realizing the transformation from the point light source to the extended surface light source, and the fiber optic panel can also be applied to other purposes.

Embodiment 2

[0049] In the light homogenizer mentioned above, there is an LED skeleton 2 between the light emitting devices, an LED support frame 3 under the LED skeleton, and a retaining ring 5 on the periphery of the circuit board.

[0050] The light-emitting device is a near-infrared light-emitting diode.

[0051] Original feature requirements:

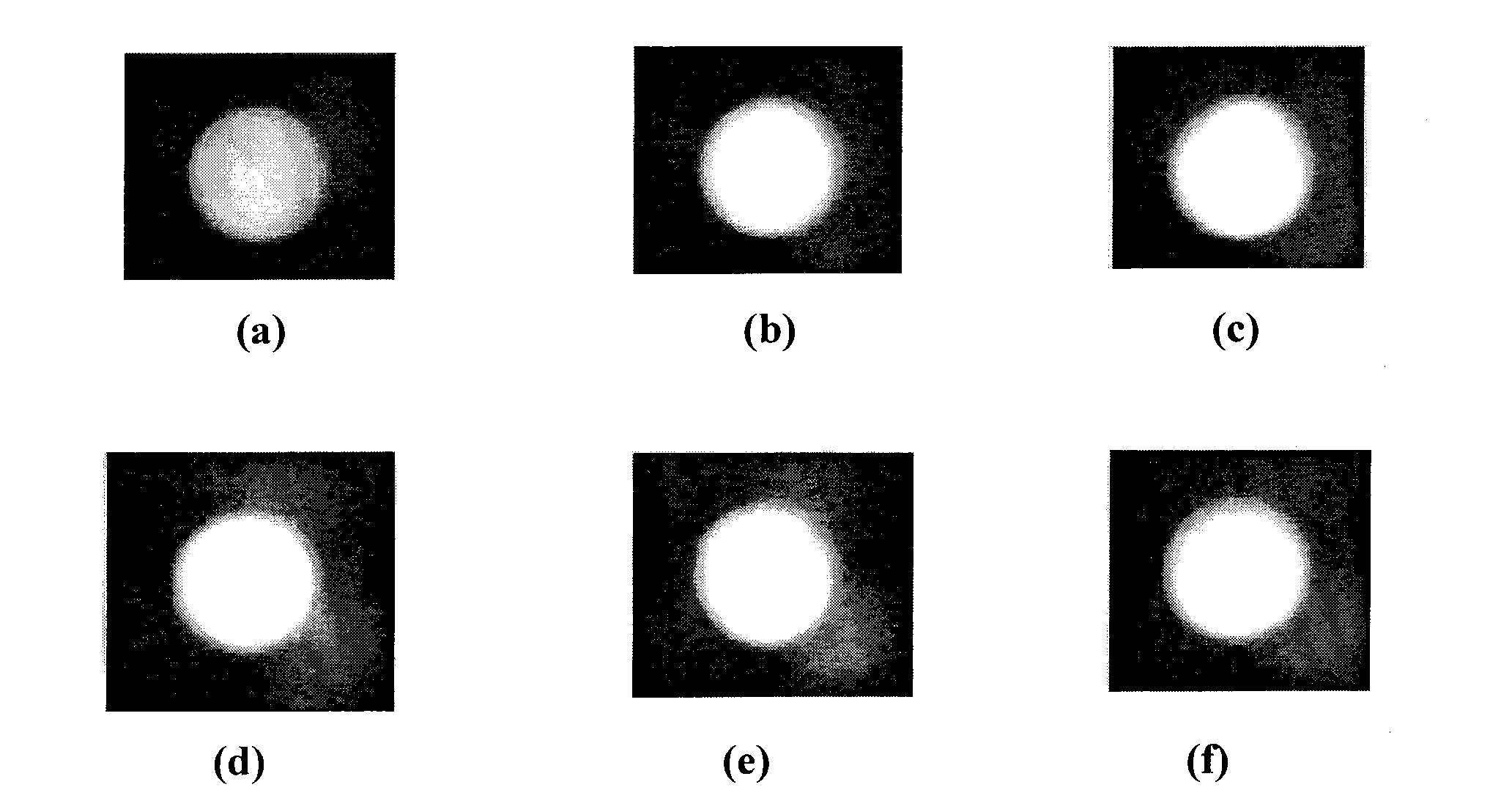

[0052] Under the condition that a group of IREDs is used in the light-emitting combination and the derating of category I is satisfied, the main optoelectronic characteristics are as follows:

[0053] (1) Forward current IF: I F =120~140mA;

[0054] (2) Forward voltage V F :V F =2.2~2.6V (measured on the circuit board);

[0055] (3) Peak wavelength λ p : λ p = λ p 0 + Δ λ p |Δλ p |≤2nm;

[0056] (4) Spectral line width Δλ 0.5 : Δλ 0.5 ≤52nm;

[0057] (5) Radiation b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com