AFc/CB/PVB modified electrode preparation and method for determining free state sulfite and amount by electrode

A technology for modifying electrodes and sulfites, applied in the field of electrochemistry, can solve the problems that the sensitivity of sulfites cannot meet the detection requirements, it is difficult to realize on-site emergency monitoring and on-line analysis, the operation is cumbersome and time-consuming, and it is inexpensive and easy to interfere. , the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Preparation of AFc / CB / PVB modifier mixture:

[0052] Weigh 0.4mg of acetylferrocene, 11.67mg of carbon powder and 10mg of polyvinyl butyral resin (PVB) and mix them evenly, add them to 1mL of absolute ethanol, stir well, and ultrasonically treat for 1-2min. Disperse the carbon powder evenly in absolute ethanol to obtain the AFc / CB / PVB modifier mixture, and let it stand for 5 minutes before use;

[0053] (2) Pretreatment of glassy carbon electrodes:

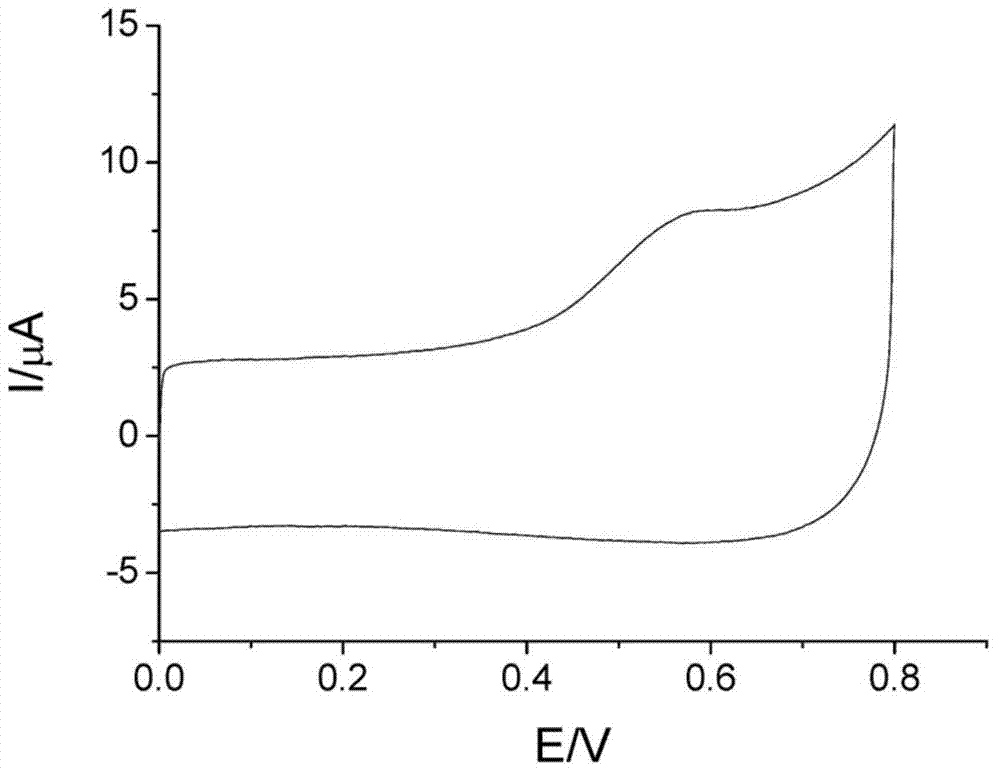

[0054] The glassy carbon electrode was polished on wet metallographic sandpaper (3000#), and then polished with a particle size of 0.3 μm polishing powder (α-Al 2 o 3 ) suspoemulsion to polish to the mirror surface, and then use 1:1 nitric acid solution, absolute ethanol and double distilled water to ultrasonically clean the glassy carbon electrode for 4 to 5 minutes respectively, and in 0.5mol / L sulfuric acid solution, the above-mentioned cleaned glassy carbon The electrode was scanned by cyclic voltammetry in the p...

Embodiment 2

[0058] (1) Preparation of AFc / CB / PVB modifier mixture:

[0059] Weigh 0.4mg of acetylferrocene, 0.67mg of carbon powder and 10mg of polyvinyl butyral resin (PVB) and mix them evenly, add them to 1mL of absolute ethanol, stir well, and ultrasonicate for 1-2min. Disperse the carbon powder evenly in absolute ethanol to obtain the AFc / CB / PVB modifier mixture, and let it stand for 5 minutes before use;

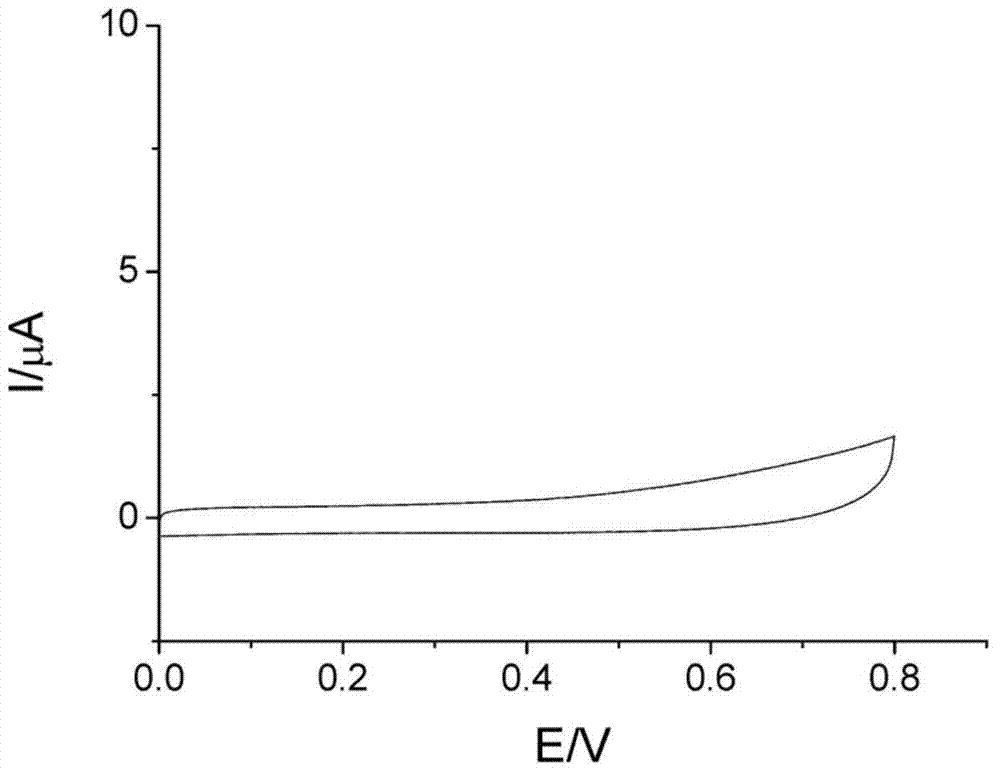

[0060] (2) Pretreatment of glassy carbon electrodes:

[0061] The glassy carbon electrode was polished on wet metallographic sandpaper (3000#), and then polished with a particle size of 0.3 μm polishing powder (α-Al 2 o 3 ) suspoemulsion to polish to the mirror surface, and then use 1:1 nitric acid solution, absolute ethanol and double distilled water to ultrasonically clean the glassy carbon electrode for 4 to 5 minutes respectively, and in 0.5mol / L sulfuric acid solution, the above-mentioned cleaned glassy carbon The electrode was scanned by cyclic voltammetry in the potential...

Embodiment 3

[0065] (1) Preparation of AFc / CB / PVB modifier mixture:

[0066] Weigh 0.033mg of acetylferrocene, 12.5mg of carbon powder and 10mg of polyvinyl butyral resin (PVB) and mix evenly, add it to 1mL of absolute ethanol, stir well, and ultrasonicate for 1-2min. Disperse the carbon powder evenly in absolute ethanol to obtain the AFc / CB / PVB modifier mixture, and let it stand for 5 minutes before use;

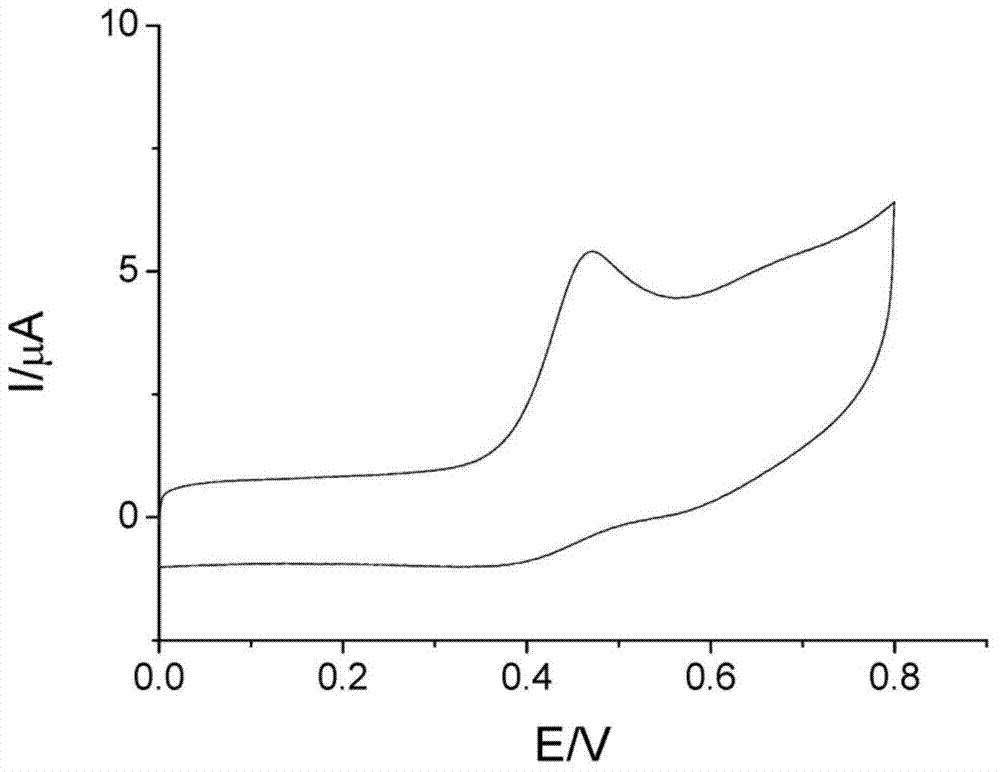

[0067] (2) Pretreatment of glassy carbon electrodes:

[0068] The glassy carbon electrode was polished on wet metallographic sandpaper (3000#), and then polished with a particle size of 0.3 μm polishing powder (α-Al 2 o 3 ) suspoemulsion to polish to the mirror surface, and then use 1:1 nitric acid solution, absolute ethanol and double distilled water to ultrasonically clean the glassy carbon electrode for 4 to 5 minutes respectively, and in 0.5mol / L sulfuric acid solution, the above-mentioned cleaned glassy carbon The electrode was scanned by cyclic voltammetry in the potential rang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com