Ball mark type coating thickness meter

A thickness gauge and coating technology, applied in the field of ball mark coating thickness gauge, can solve the problems of inability to meet the requirements of convenient and rapid detection of coating thickness, large equipment volume and high equipment cost, and achieve short measurement cycle and equipment volume. Small, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

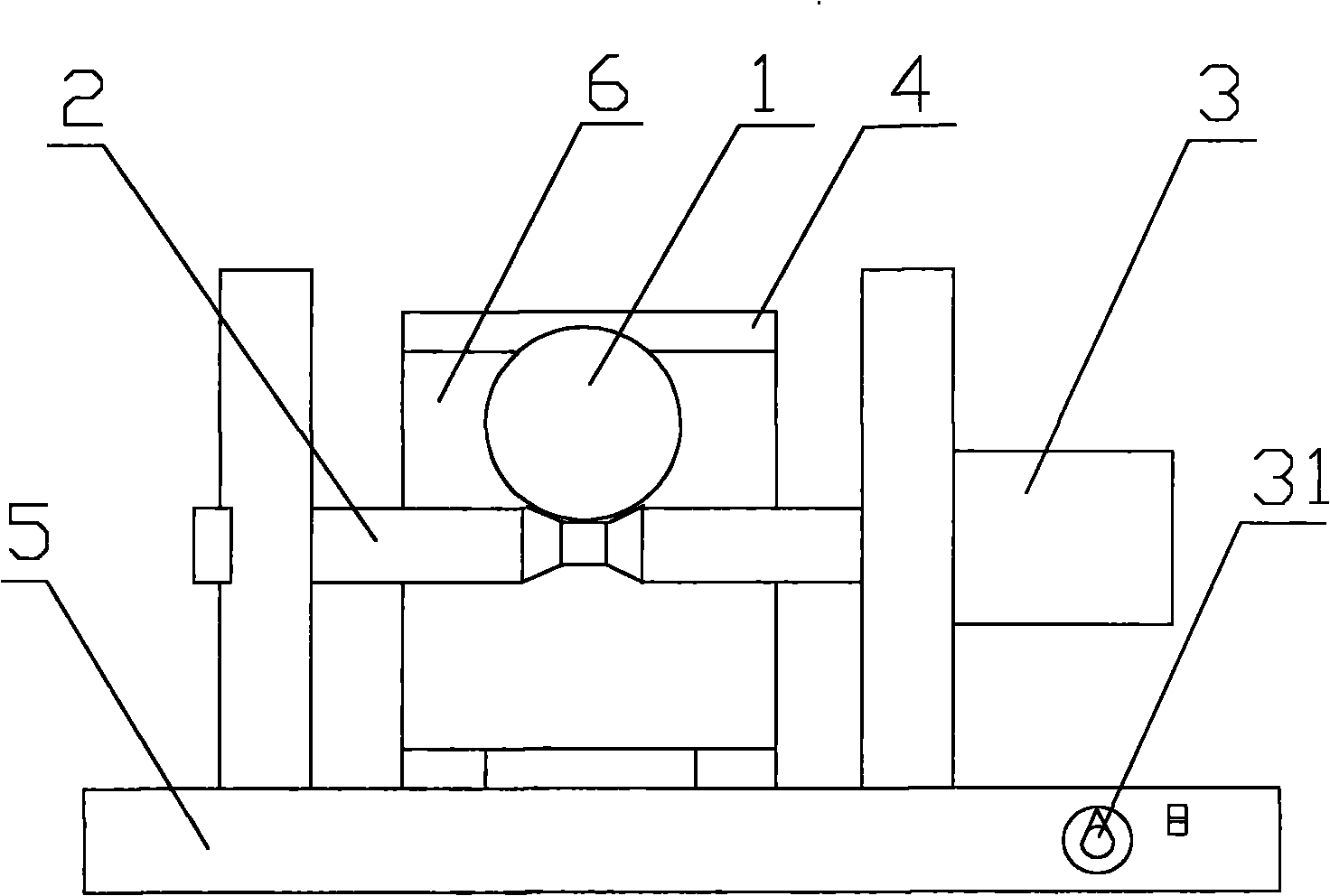

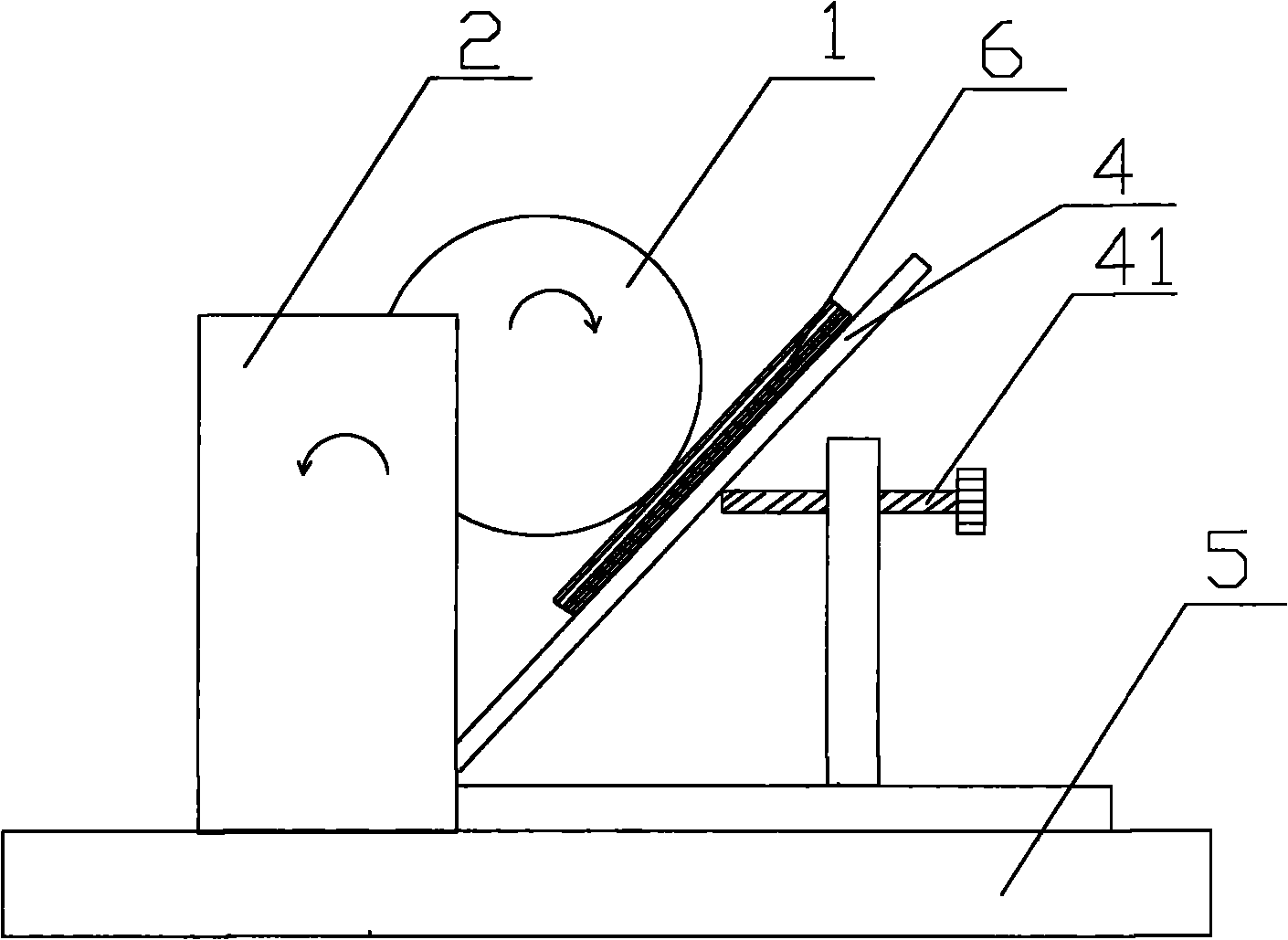

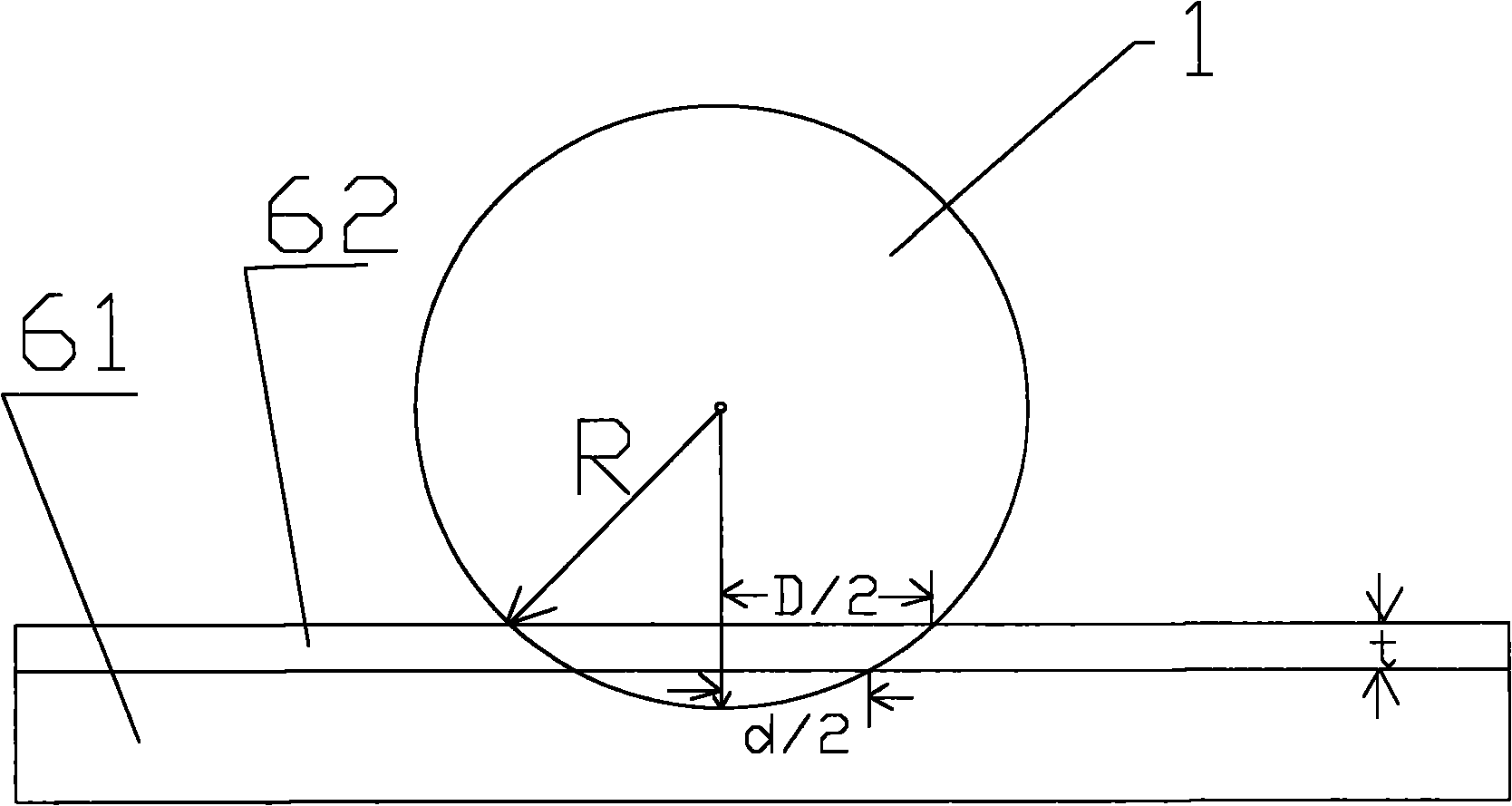

[0022] Below in conjunction with accompanying drawing embodiment, illustrate the structural principle of the present invention as follows:

[0023] Such as figure 1 , figure 2 As shown, the structure of the ball mark type coating thickness gauge of the present invention includes a grinding ball 1, a rotating arm 2, a motor 3, a detection table 4, and an instrument frame 5; the rotating arm 2, the motor 3, and the detection table 4 are arranged on the instrument frame 5 , The grinding ball 1 is placed between the rotating arm 2 and the detection table 4 and pressed on the surface of the detection table 4; the motor 3 is connected with the rotating arm 2 through mechanical transmission.

[0024] The rotating arm 2 is provided with a trapezoidal groove; the grinding ball 1 is placed in the trapezoidal groove, and when the motor 3 drives the rotating arm 2 to rotate, the trapezoidal groove rubs against the grinding ball 1 to make the grinding ball 1 rotate.

[0025] The detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com