Miniature integrated temperature control type CO2 gas sensor and manufacturing method thereof

A gas sensor and temperature-controlled technology, which is applied in the field of micro-integrated temperature-controlled CO2 gas sensor and preparation, to achieve the effects of stable process, simplified processing technology and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

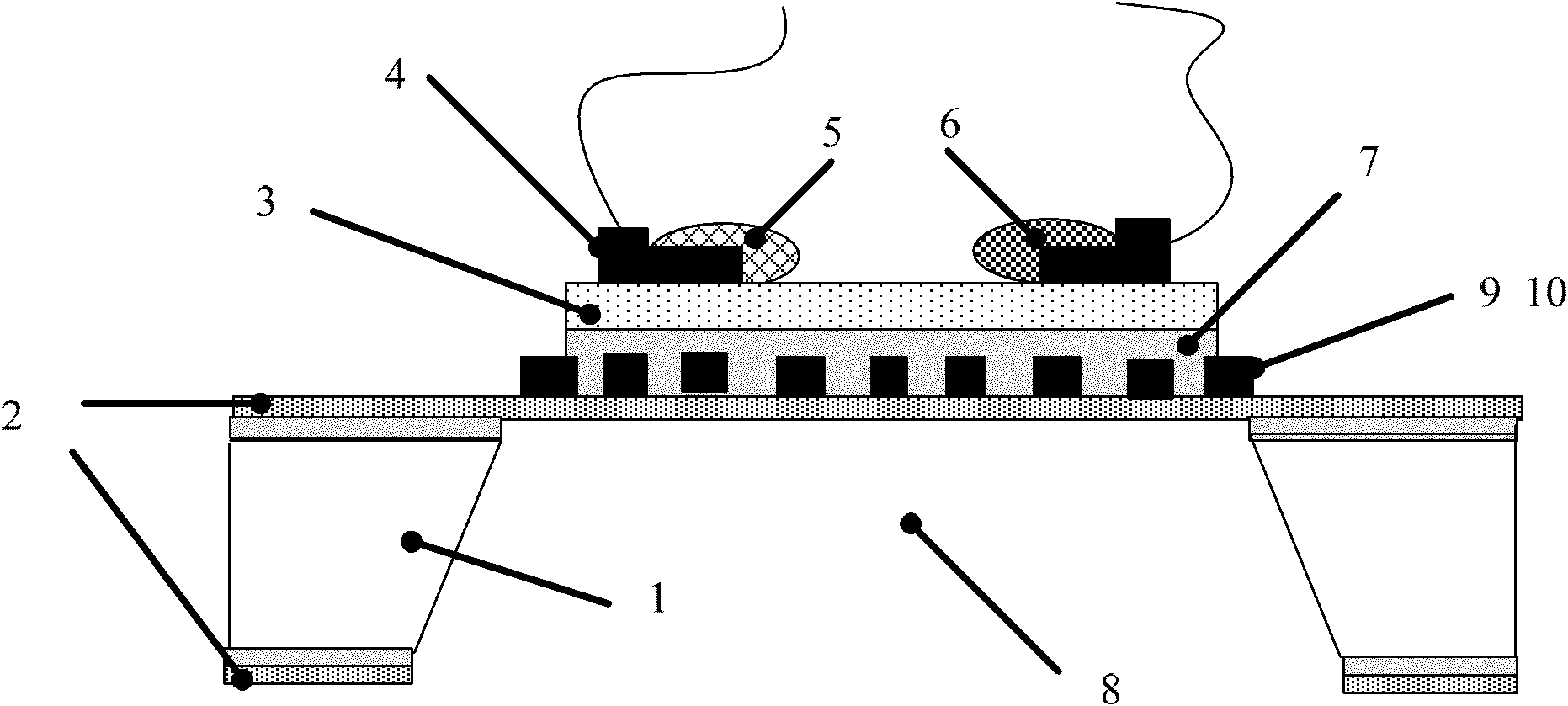

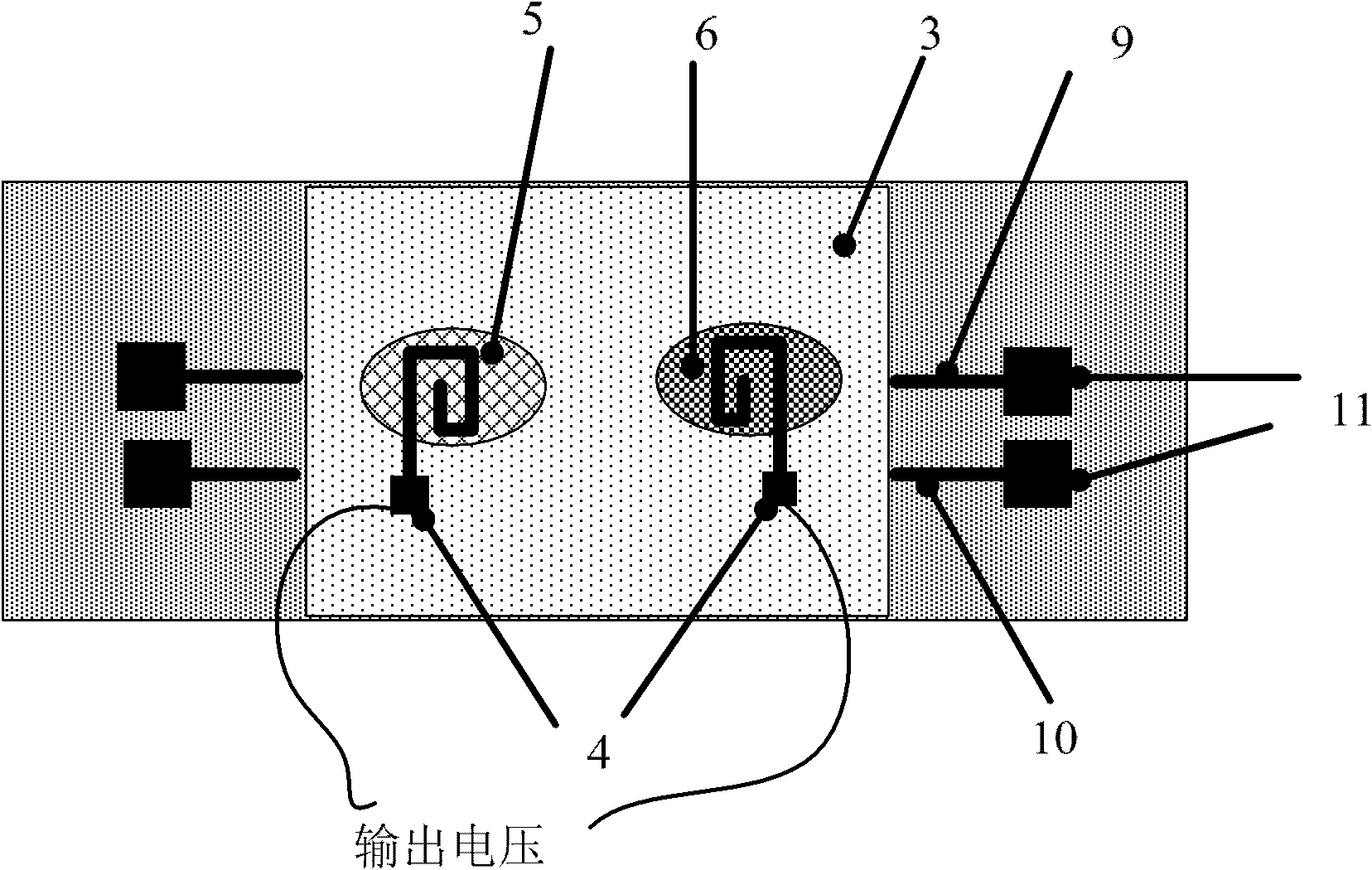

[0024] Such as figure 1 As shown, a micro-integrated temperature-controlled solid electrolyte CO based on MEMS technology 2 Gas sensor, on a silicon substrate (with SiO on both sides 2 )1 double-sided deposited Si 3 N 4 Layer 2, by dry etching away the Si 3 N 4 Layer, wet etching process to process the thermal window 8 structure, on the other side of the silicon substrate Si 3 N 4 The Pt heating electrode 9 and the temperature measuring electrode 10 are processed by a photolithographic lift-off process on the layer, and then SiO is deposited. 2 The insulating protective layer 7 covers the Pt heating electrode and the Pt temperature measuring electrode, and exposes the junction pad 11, after which the SiO 2 Deposit Li on layer 7 3 PO 4 Solid electrolyte film 3, and prepare two Pt conductive thin films 4 thereon, prepare Li respectively on two conductive thin films 2 CO 3 Reaction electrode 5 and Li 2 TiO 3 / TiO 2 Reference electrode 6.

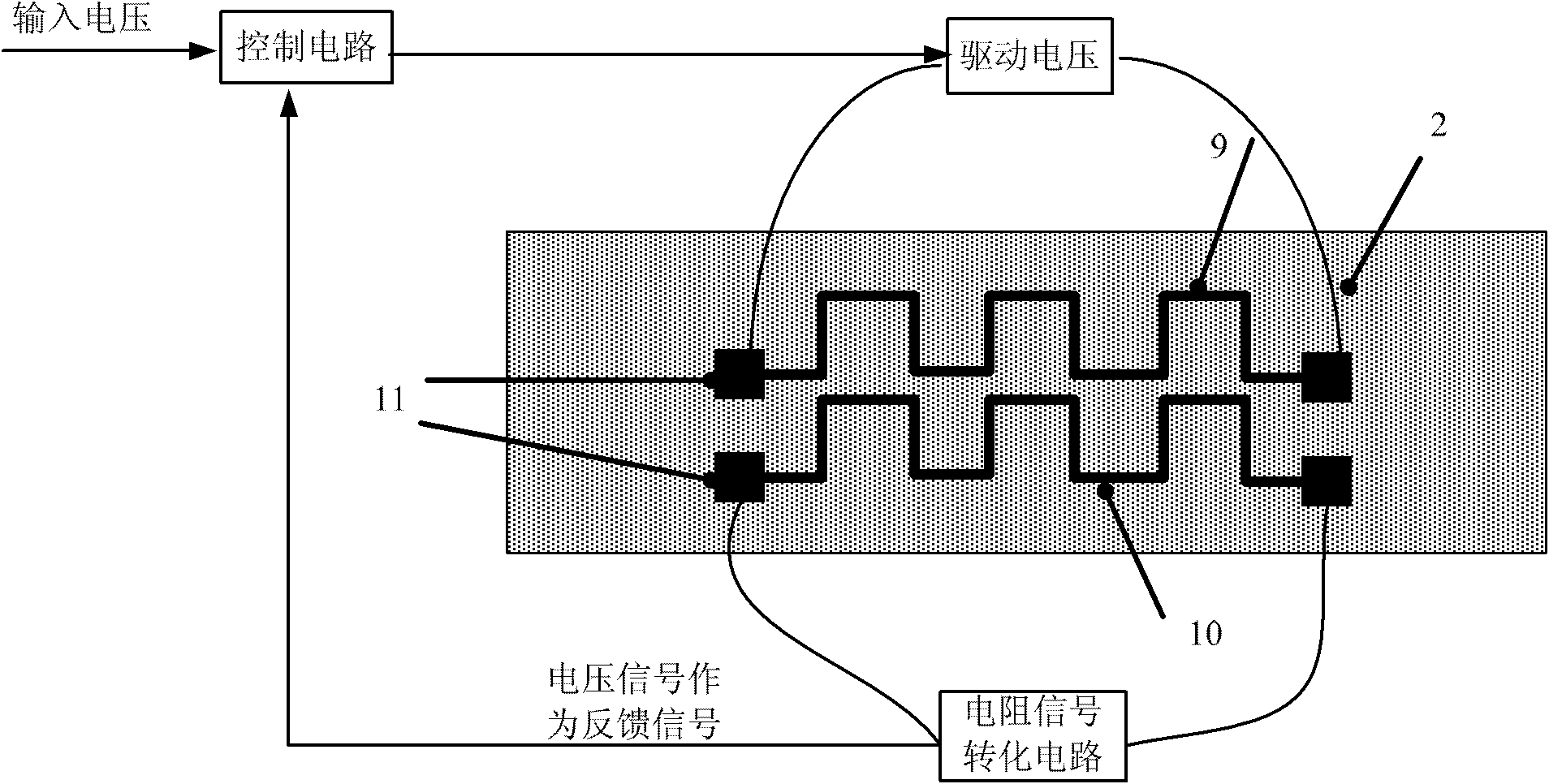

[0025] Such as figure 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com