NbTi/YBCO (yttrium barium copper oxide) composite superconducting wire with circular section

A circular cross-section, superconducting wire technology, applied in superconducting devices, superconducting/high-conducting conductors, usage of superconducting elements, etc., can solve the problems of reduced current density in superconducting engineering, rising superconducting temperature, superconducting quenching, etc. problem, to achieve the effect of increasing the superconducting operating current, high shunt temperature, and reducing the current margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

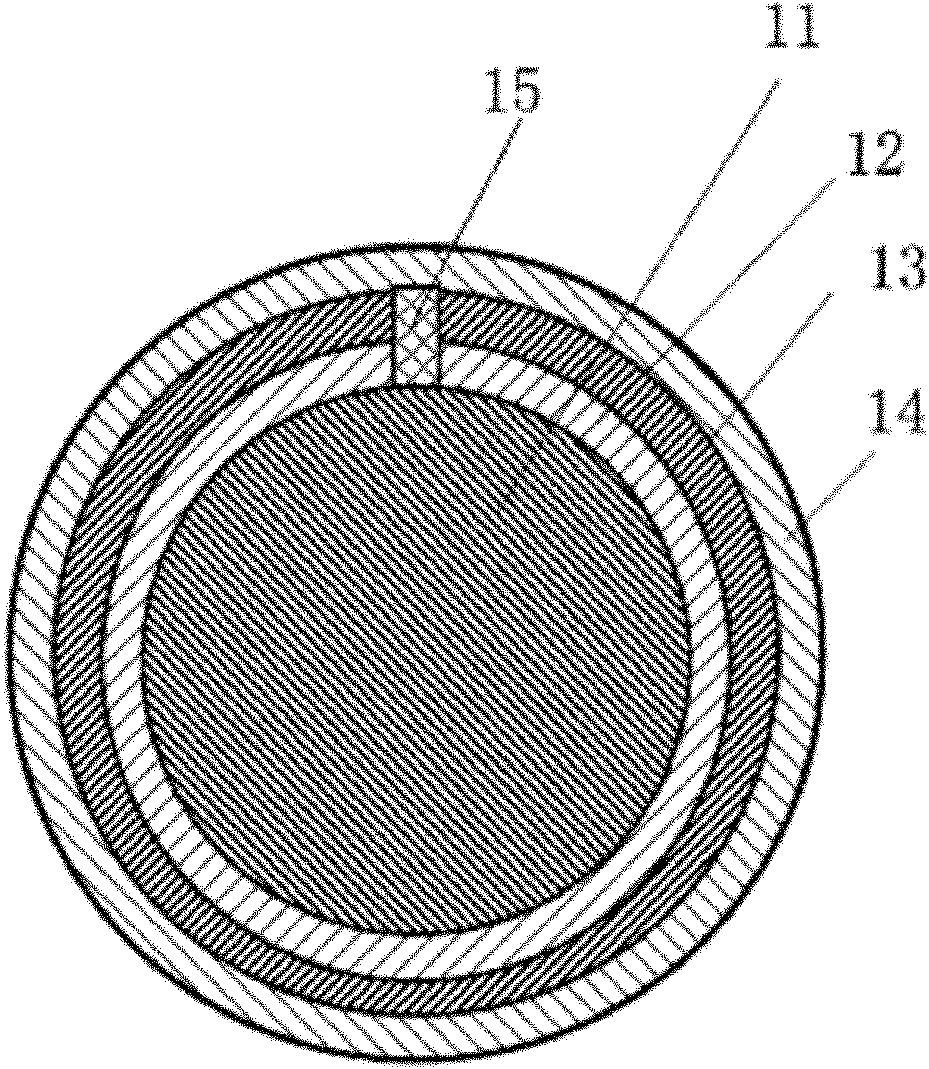

[0024] figure 1 It is a schematic cross-sectional view of the circular cross-section NbTi / YBCO composite superconducting wire of the embodiment. The circular cross-section NbTi / YBCO composite superconducting wire is composed of a low-temperature superconducting wire 11, a stabilizing layer 12, a high-temperature superconducting matrix layer 13, a high-temperature superconducting coating 14, and an Ag weld 15. The circular cross-section low-temperature superconducting wire 11 consists of a stabilizing layer 12 cladding, the high-temperature superconducting matrix layer 13 is rolled and coated on the stable layer 12, the Ag solder welds the high-temperature superconducting matrix layer 13 in the rolling seam of the high-temperature superconducting matrix layer to form an Ag weld 15, and the high-temperature superconductor is coated Layer 14 is coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com