Absorbent pads and method of making such pads

A technology for absorbent pads and absorbent bodies, which is applied in the field of manufacturing absorbent pads and can solve problems such as unpleasantness and expensive production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Figure 1-5 Example of

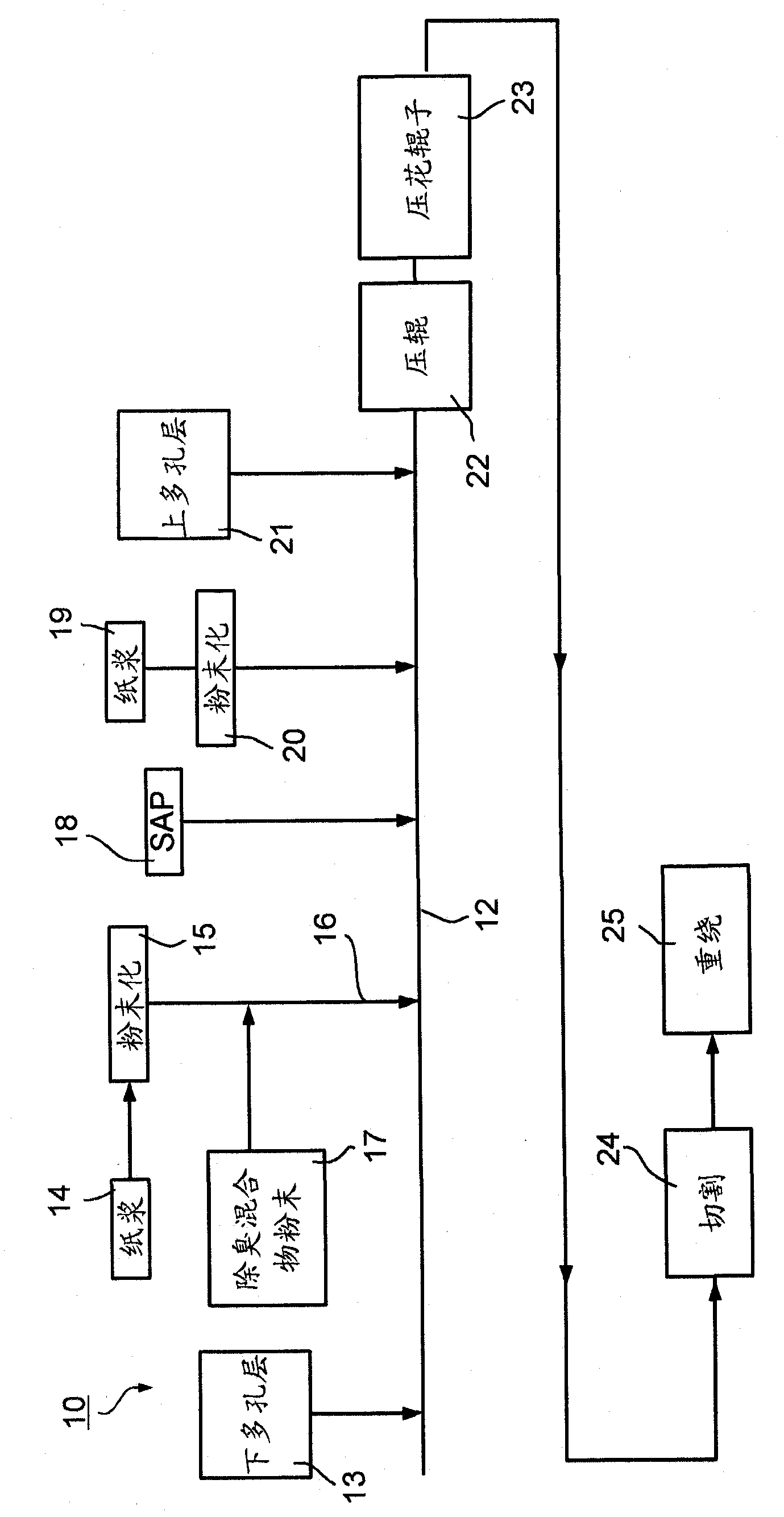

[0035] figure 1 A production line is schematically illustrated, generally indicated at 10, for the manufacture of absorbent pads according to the invention. according to figure 1 The absorbent pad is manufactured in figure 2 described in.

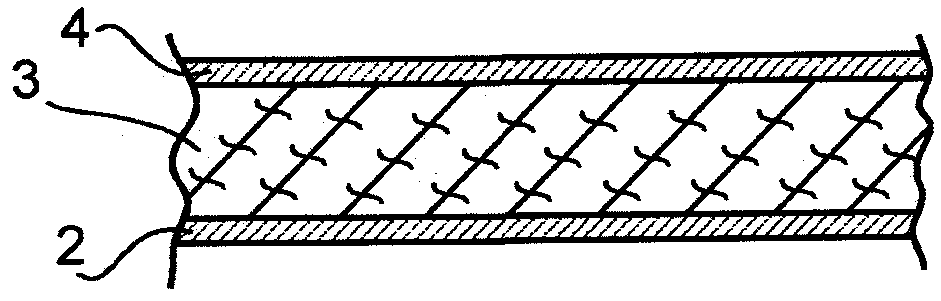

[0036] Depend on figure 1 Manufactured on line 10 in and in figure 2 The absorbent pad shown in is a three-layer pad comprising a lower porous layer 2, a middle layer 3 of absorbent powdered pulp, and an upper porous layer 4. As will be described in more detail below, figure 1 and 2 The three-layer absorbent pad in can be used alone, or it can be used as a core for making absorbent pads with more than three layers, e.g. Figure 6 and 7 Five layers of absorbent pads in .

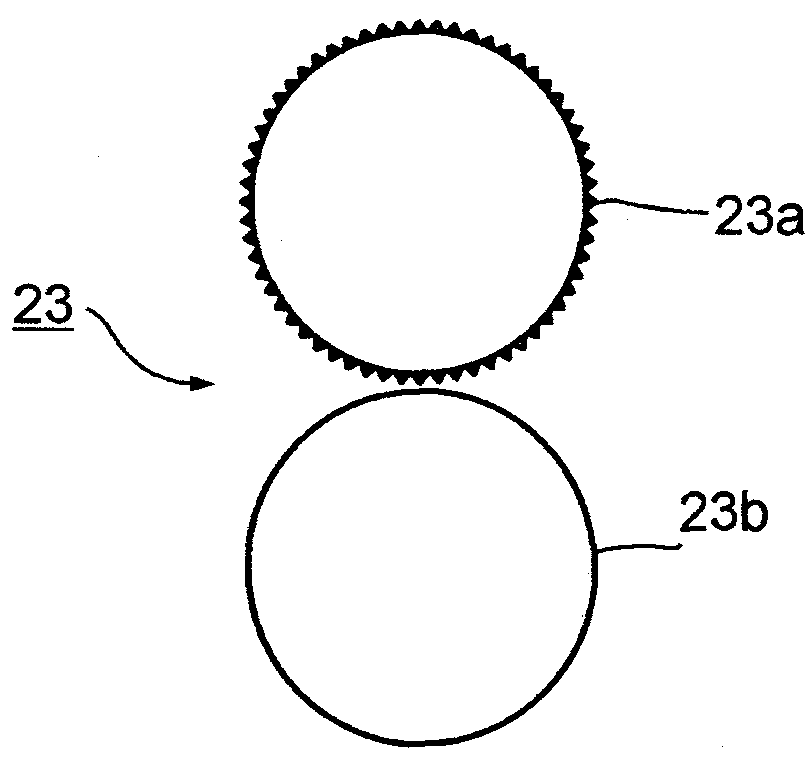

[0037] thus, figure 1 The production line 10 shown in includes a fabric (web) 12 that passes through a plurality of stations to which different materials are applied and processed to manufacture figure 2 The three-laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com