Liquid-gas suspension electric main shaft

An electric spindle, hydraulic and gas technology, applied in the direction of metal processing equipment, etc., can solve the problems of spindle system dynamic stiffness and rotation accuracy changes, processing efficiency or processing accuracy changes, processing accuracy decline, etc., to achieve the best dynamic stiffness and rotation accuracy , taking into account the accuracy and efficiency, avoiding the effects of clamping errors and repeated positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

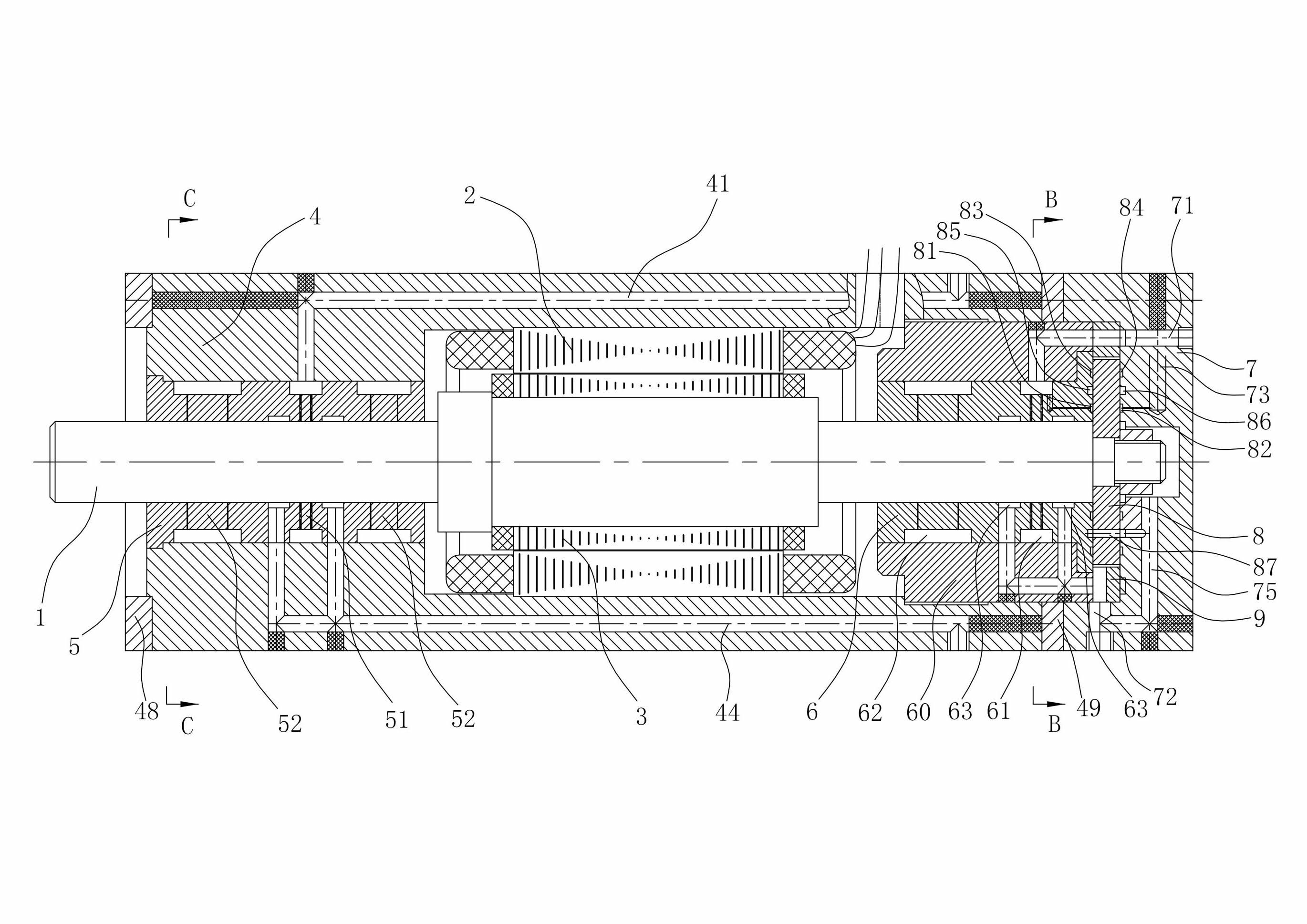

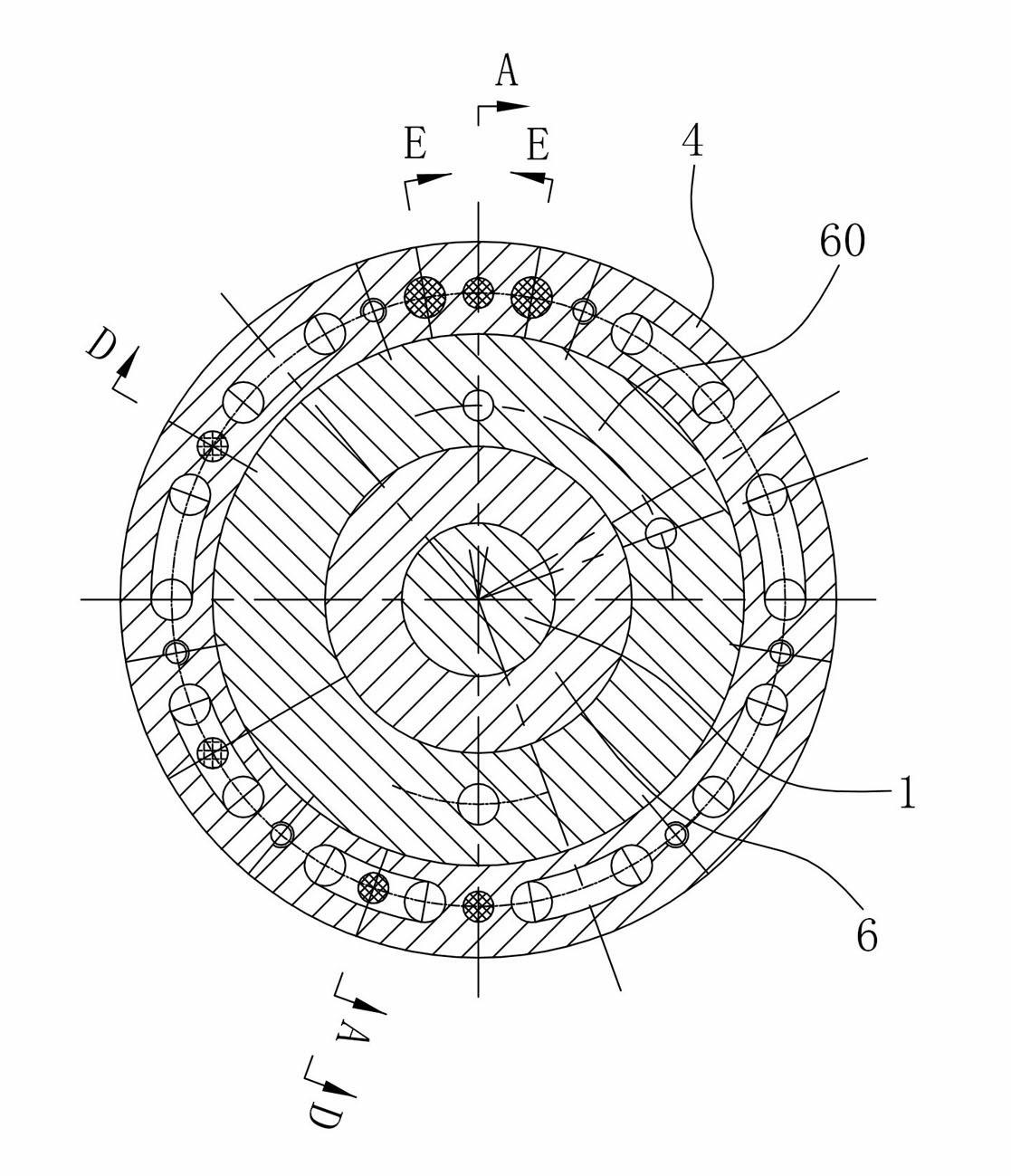

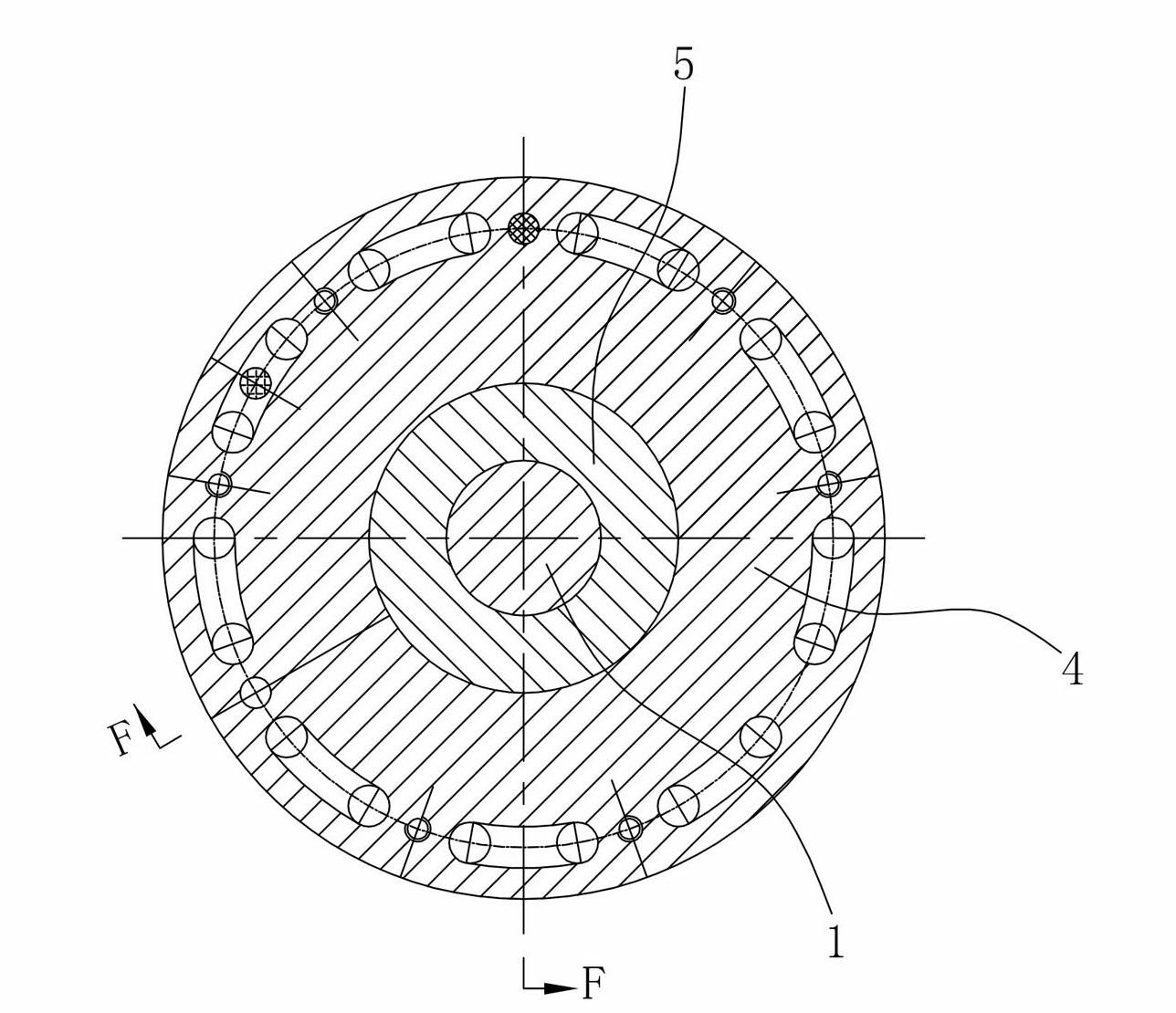

[0026] Figure 1 to Figure 6 It shows an embodiment of a liquid-pneumatic suspension electric spindle of the present invention, which includes a spindle 1, a motor stator 2, a motor rotor 3, a box body 4, a front bearing assembly 5, a rear bearing assembly 6 and a rear end cover 7. The motor stator 2 is set in the box body 4, the motor rotor 3 is set on the main shaft 1, the main shaft 1 is placed in the motor stator 2, and is supported on the box body 4 by the front bearing assembly 5 and the rear bearing assembly 6 Above, the rear end cover 7 is mounted on the rear end of the box body 4, and the front bearing assembly 5 is provided with at least one front liquid bearing 51 and at least one front gas bearing 52, the front liquid bearing 51 and the front gas bearing 52 are arranged axially, The rear bearing assembly 6 is provided with at least one rear fluid bearing 61 and at least one rear gas bearing 62. The rear fluid bearing 61 and the rear gas bearing 62 are arranged axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com