Iron-based nanocrystalline soft magnetic alloy with high quenching state toughness and wide annealing temperature range

An iron-based nanocrystal, annealing temperature technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of increasing scrap rate, complex shape of iron core, increasing alloy cost, etc., to improve performance stability, excellent softness and so on. Magnetic properties, the effect of reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below through several groups of examples and comparative examples, but the present invention is not limited to these examples.

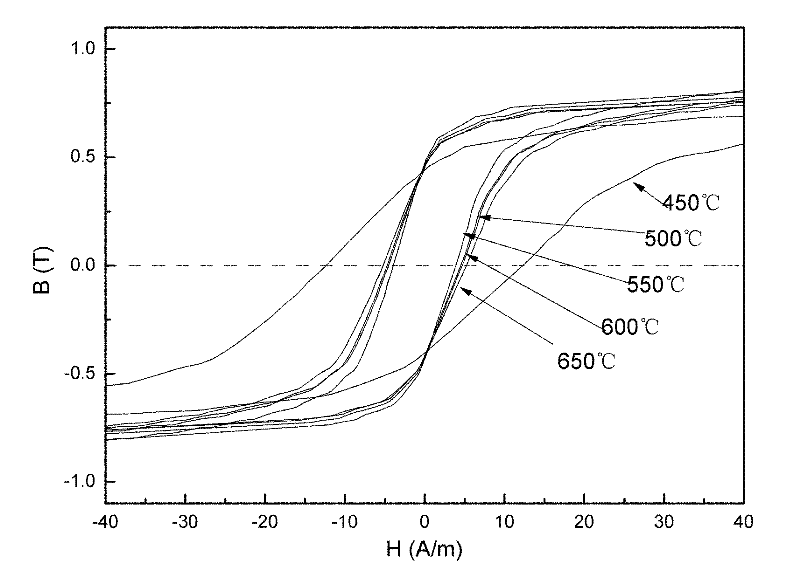

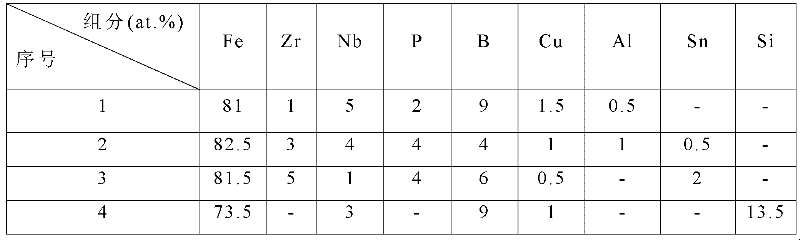

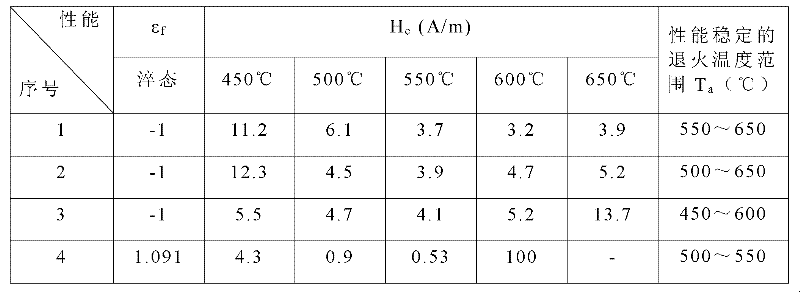

[0011] According to the composition range (atomic percentage) of the iron-based nanocrystalline soft magnetic alloy of the present invention, prepared 3 groups of embodiments, and prepared 1 group of comparative examples (Finemet) under the same conditions, the composition ratio is shown in Table 1 (wherein Sequence number 1-3 is embodiment, and 4 is comparative example).

[0012] Table 1 Comparison of the composition of the embodiment of the present invention with the existing typical nanocrystalline soft magnetic alloy Finemet

[0013]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com