Aeroacoustic rotor blade for a wind turbine, and wind turbine equipped therewith

A technology of rotor blades and wind power equipment, applied in the field of wind power equipment, can solve the indispensable pursuit of reducing the noise generated by wind power equipment, and achieve the effects of reduced noise emission, strong noise reduction, and low power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

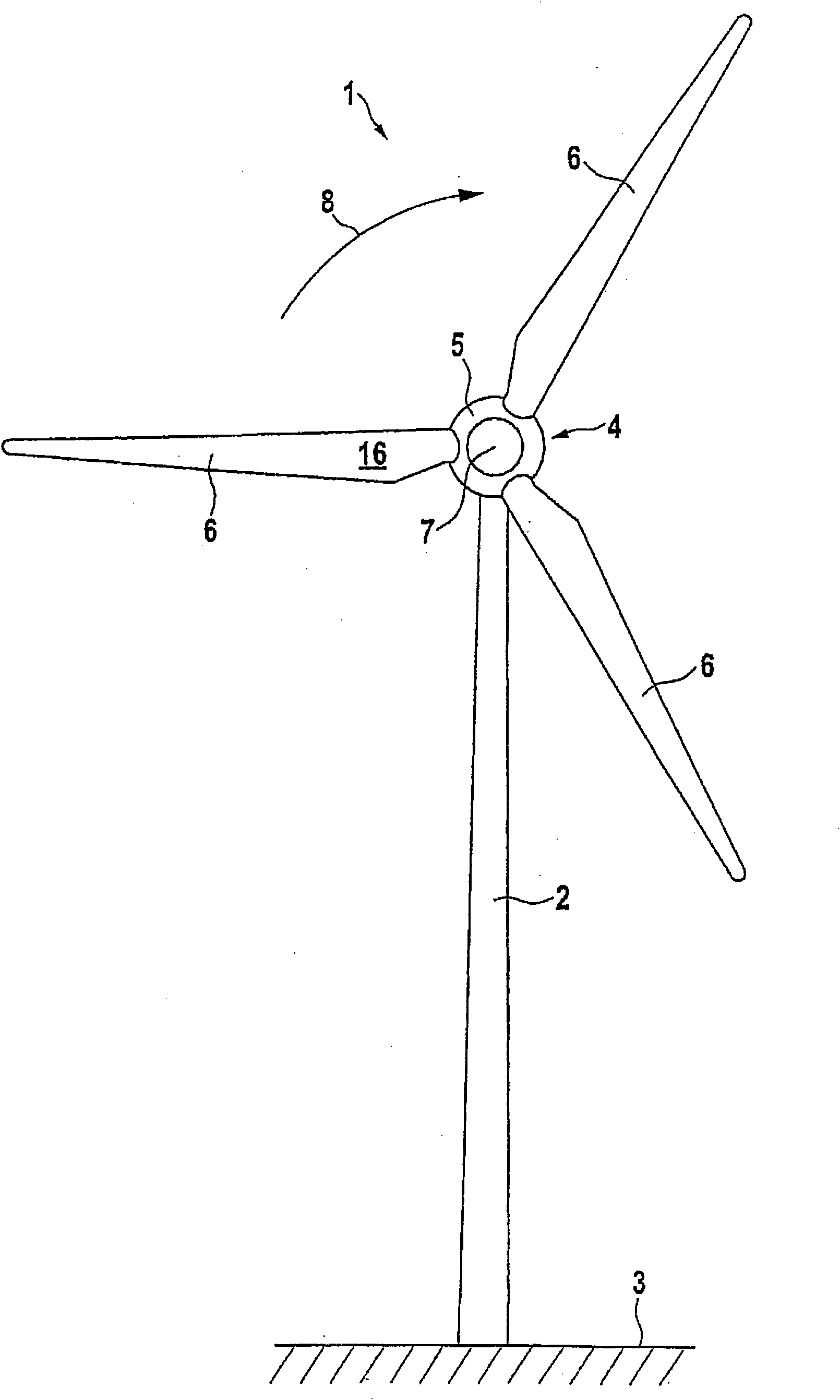

[0036] figure 1 Shown is a wind power installation 1 according to the invention, which consists of a tower 2 fixedly anchored in a foundation 3 with a bottom region and a rotor 4 arranged in the top region of the tower 2, which rotates around the The axis of rotation 7 of the viewing plane rotates in the direction of the arrow 8 . The rotor 4 has a hub 5 rotatably supported on top of the tower 2 and coupled to a generator for generating electricity. The rotor blades 6 are connected to the rotor 4 in the region of the hub 5 .

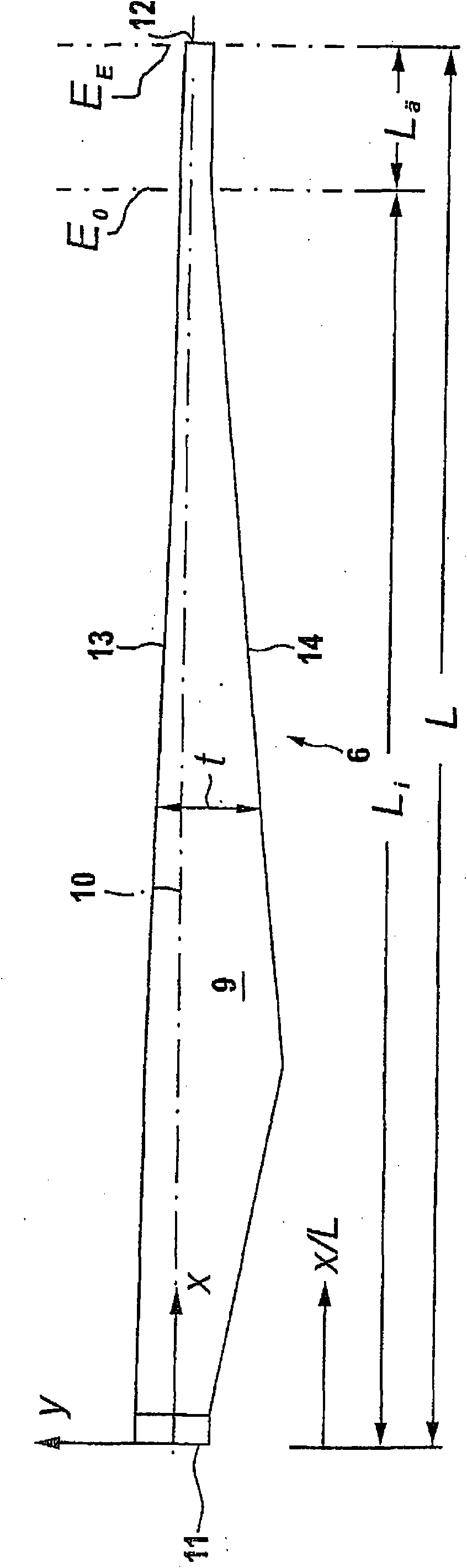

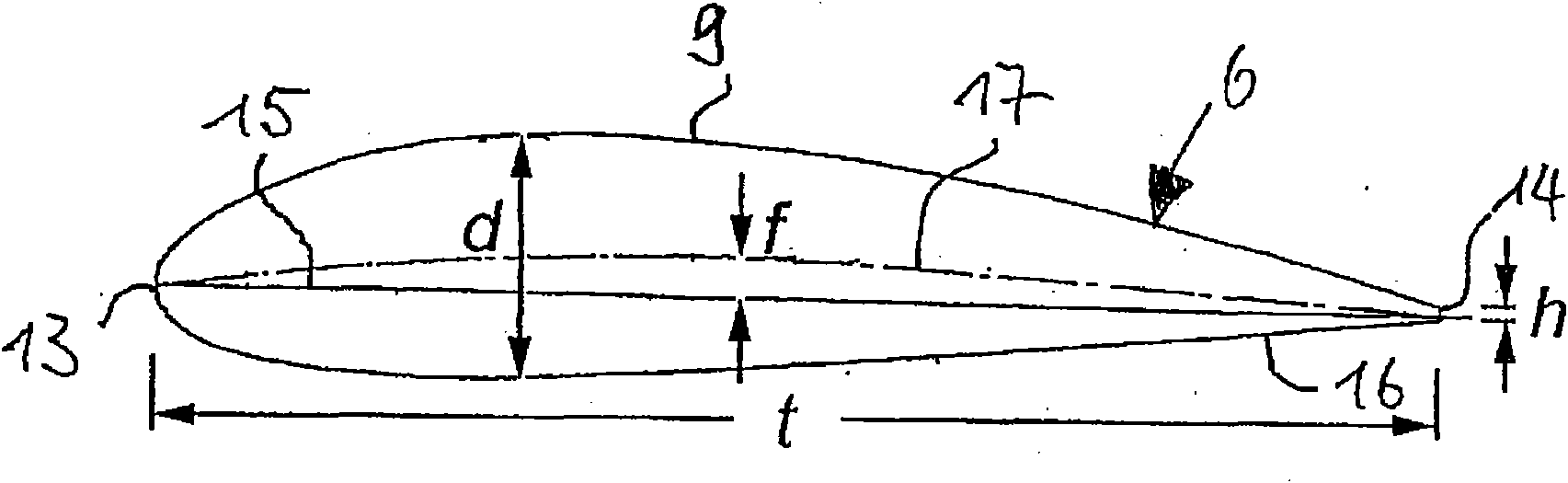

[0037] exist figure 2 The top view of the suction side 9 shows the rotor blades 6 of the rotor 4 on a larger scale. The longitudinal extension of the rotor blade 6 along its longitudinal axis 10 is denoted as length L and is determined by the distance of the blade joint 11 from the blade end 12 . The relative length x / L represents any position starting from the blade joint 11 between the blade joint 11 and the blade end 12 .

[0038] also figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com