Method for eliminating defects of main insulation of cold insulation superconducting cable and system structure for realizing method

A technology of superconducting cables and primary insulation, which is applied in the usage of superconducting elements, superconducting devices, and cable accessories for low-temperature cables, etc., and can solve problems such as deterioration of insulation performance, inability to use insulating oil, and inability to fill insulating air gaps. To achieve the effect of simplifying the process, reducing the production cost and facilitating the process plan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

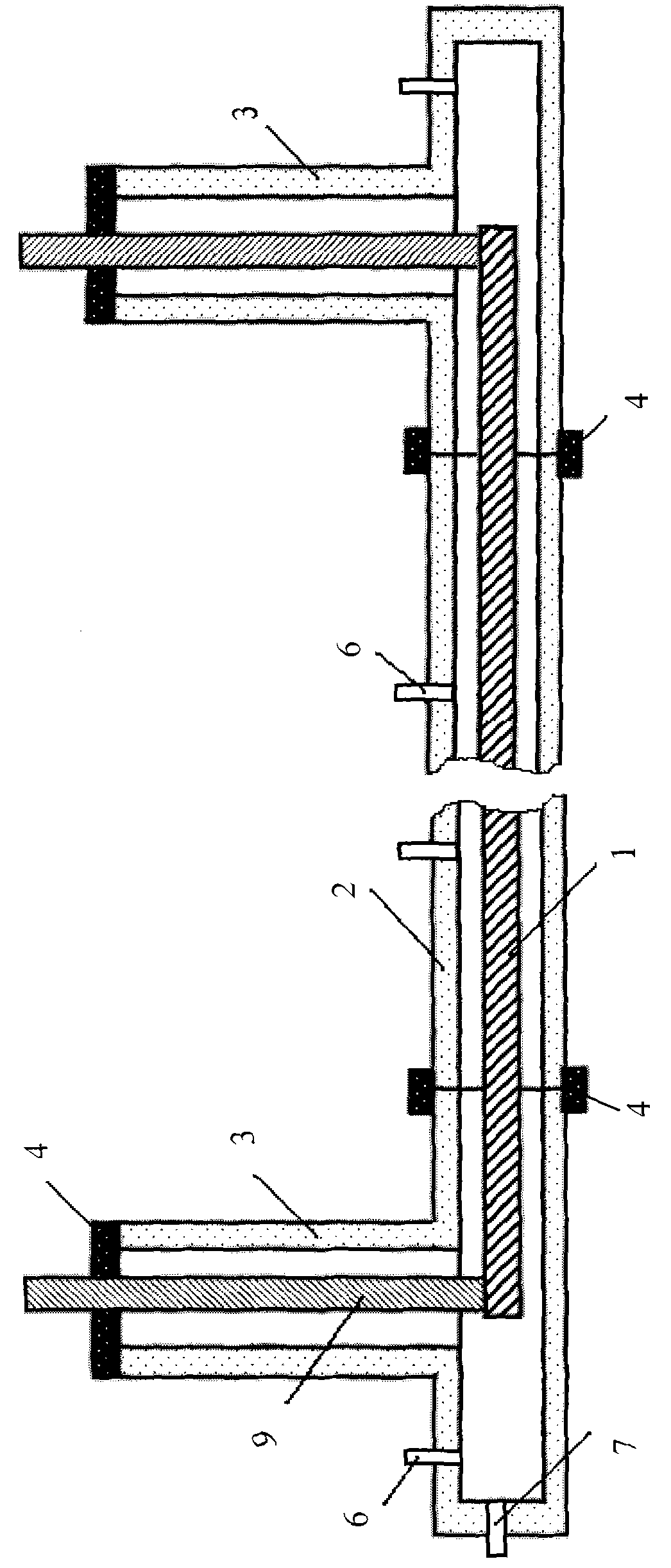

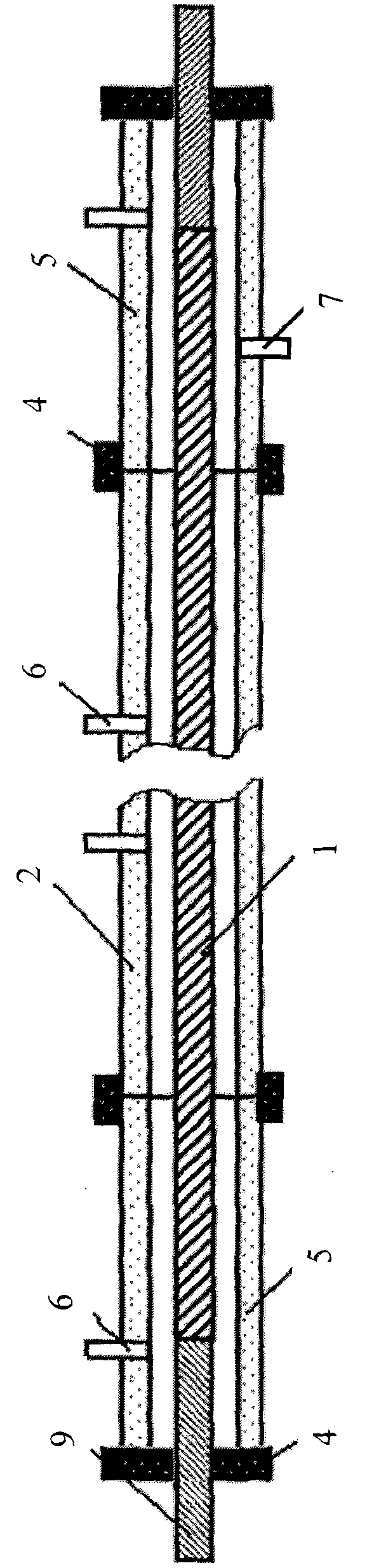

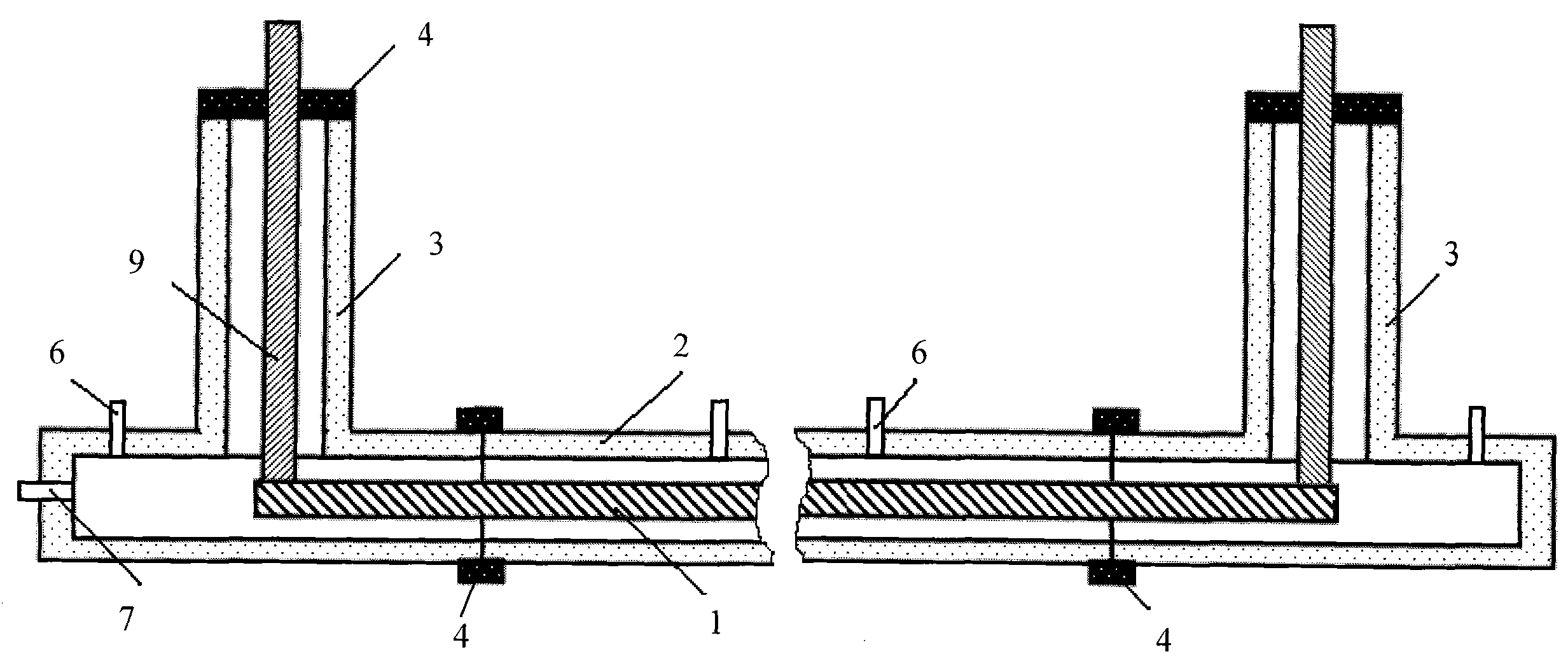

[0029] In order to realize the method for eliminating defects of the main insulation of the cold-insulated superconducting cable of the present invention, at first the assembly structure of the cold-insulated superconducting cable should be newly designed, such as figure 1 As shown, firstly, the original assembly structure of the main body is maintained, that is, the connection between the superconducting cable body (consisting of the superconducting cable core 1 and the cable cryostat 2) and the cable terminal 3 (including the sealing flange 4 for the cable terminal) , the cable terminal 3 and the cable cryostat 2 are connected through a sealing flange 4 to form a sealed cable cavity. When the superconducting cable is running, the cable cavity is a liquid nitrogen flow channel, which provides a low temperature environment for the cable core.

[0030] In addition to being connected to the cable terminal, the cable body can also be connected to the special cable head 5 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com