Technology and system for recycling high-purity cut silicon powder

A recovery system and silicon powder technology, applied in the fields of physics and semiconductor materials, can solve the problems of long process cycle, large energy consumption, and high recovery cost, and achieve the effects of purifying the environment, reducing energy consumption, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

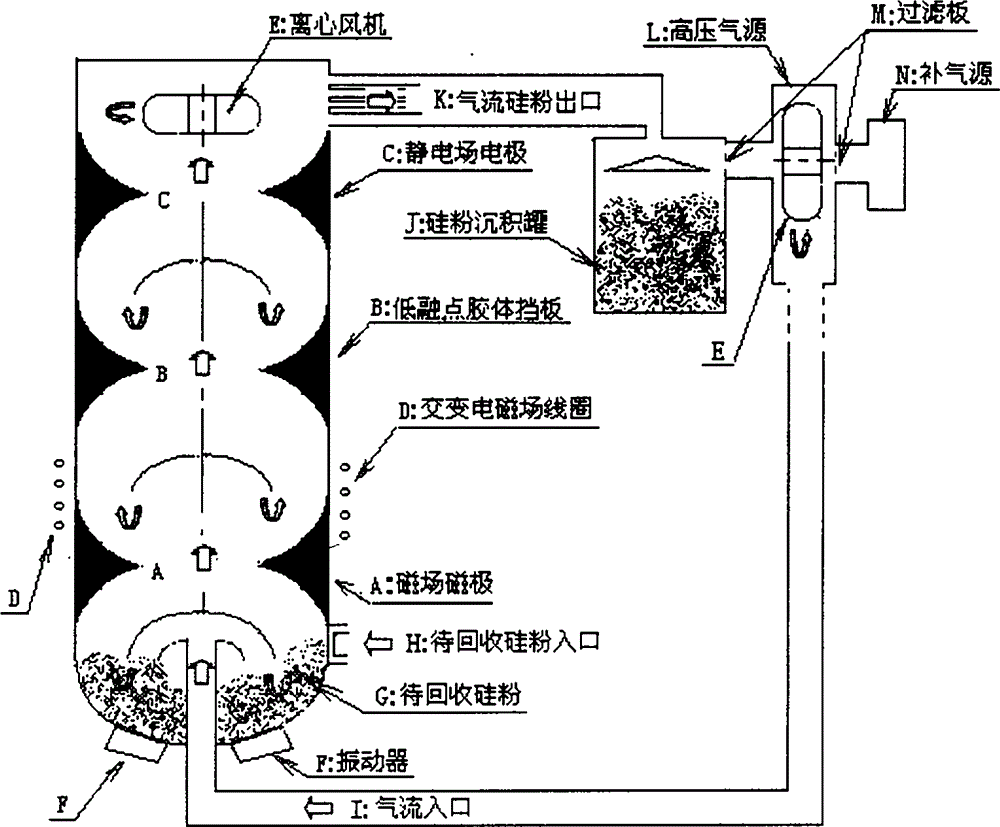

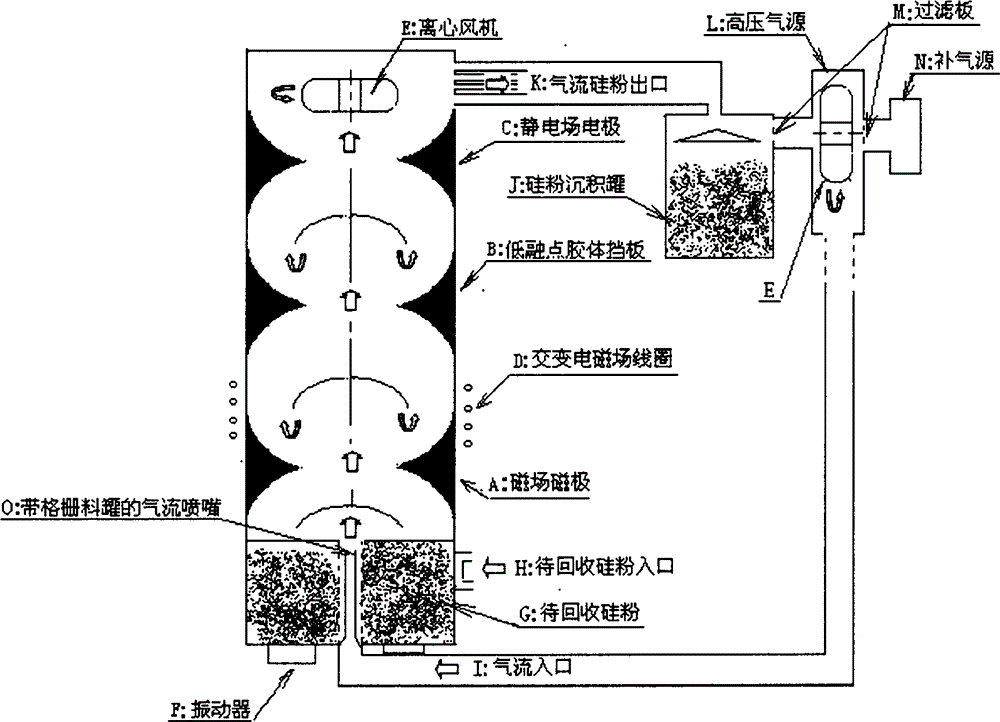

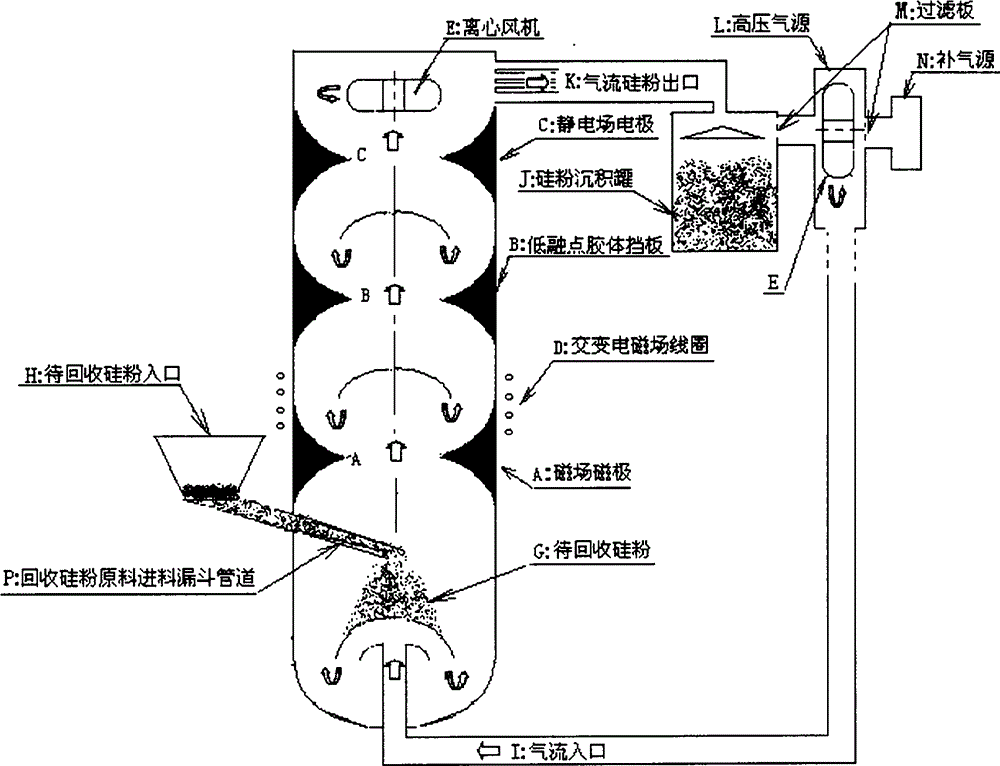

[0017] (1): Three-dimensional space separation system:

[0018] Refer to attached figure 1 , Bottom feeding silicon powder recovery device is composed of high-pressure air source; magnetic field pole; low melting point colloidal baffle; electrostatic field electrode; alternating electromagnetic field coil; centrifugal fan;

[0019] The high-pressure air source is composed of a purification filter system, pipes, nozzles and centrifugal fans. The gas inlet is connected to the silica powder recovery sedimentation tank and the purified gas source, and the gas outlet is connected to the nozzle by the pipe.

[0020] The magnetic poles of the magnetic field are composed of permanent magnets and hard magnetic tapes, and are installed downstream of the inlet pipeline of the silicon powder to be recovered in the recovery system. The permanent magnet is fixed on the pipe, and the hard magnetic tape is attached to the surface of the permanent magnet to contact with the silicon powder ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com