Pretreatment technique and equipment for degrading high-concentration organic waste water by power ultrasonic cavitation

An organic wastewater, high concentration technology, applied in the direction of oxidation water/sewage treatment, mechanical oscillation water/sewage treatment, neutralization water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The preparation implementation of the present invention explains:

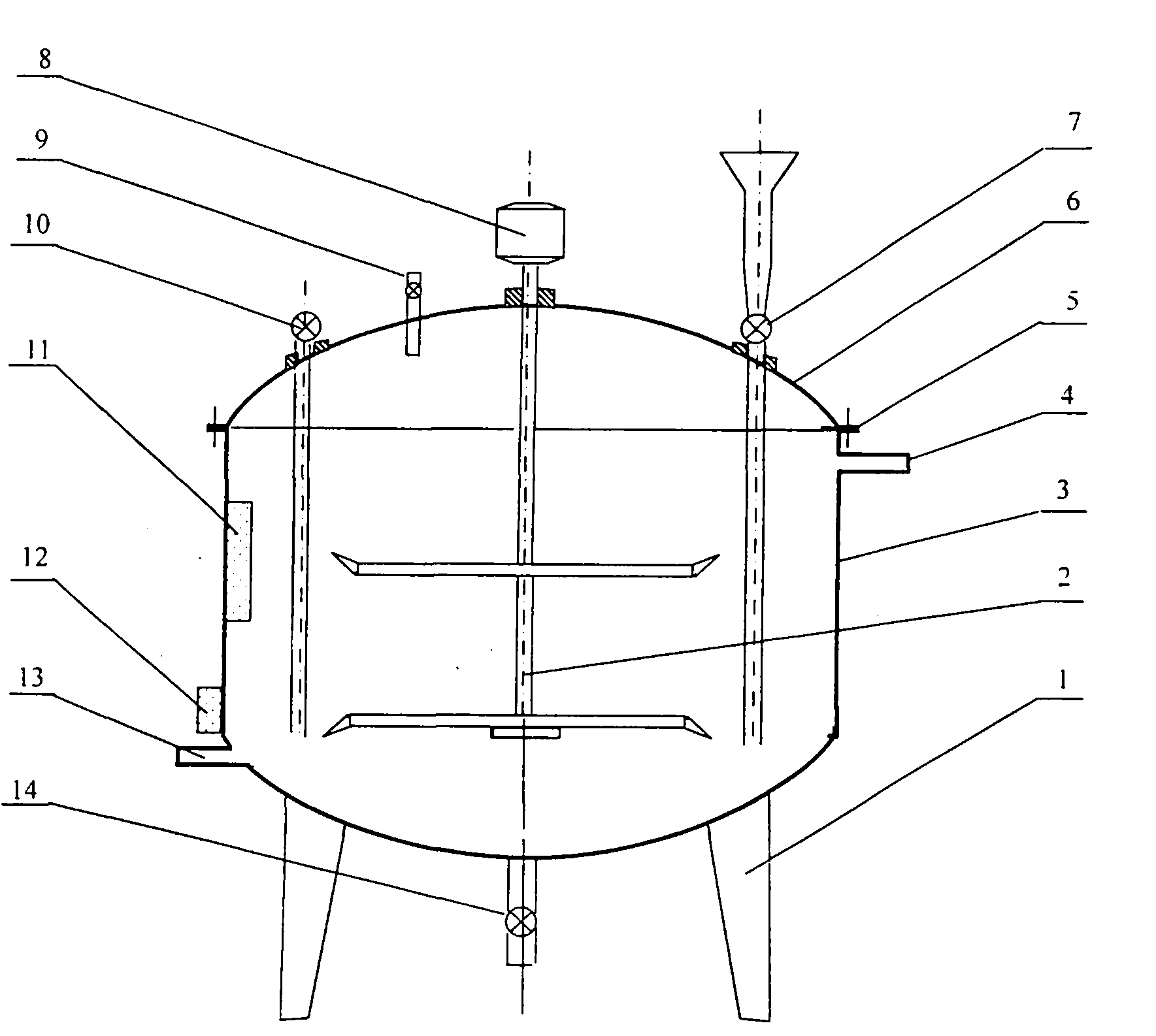

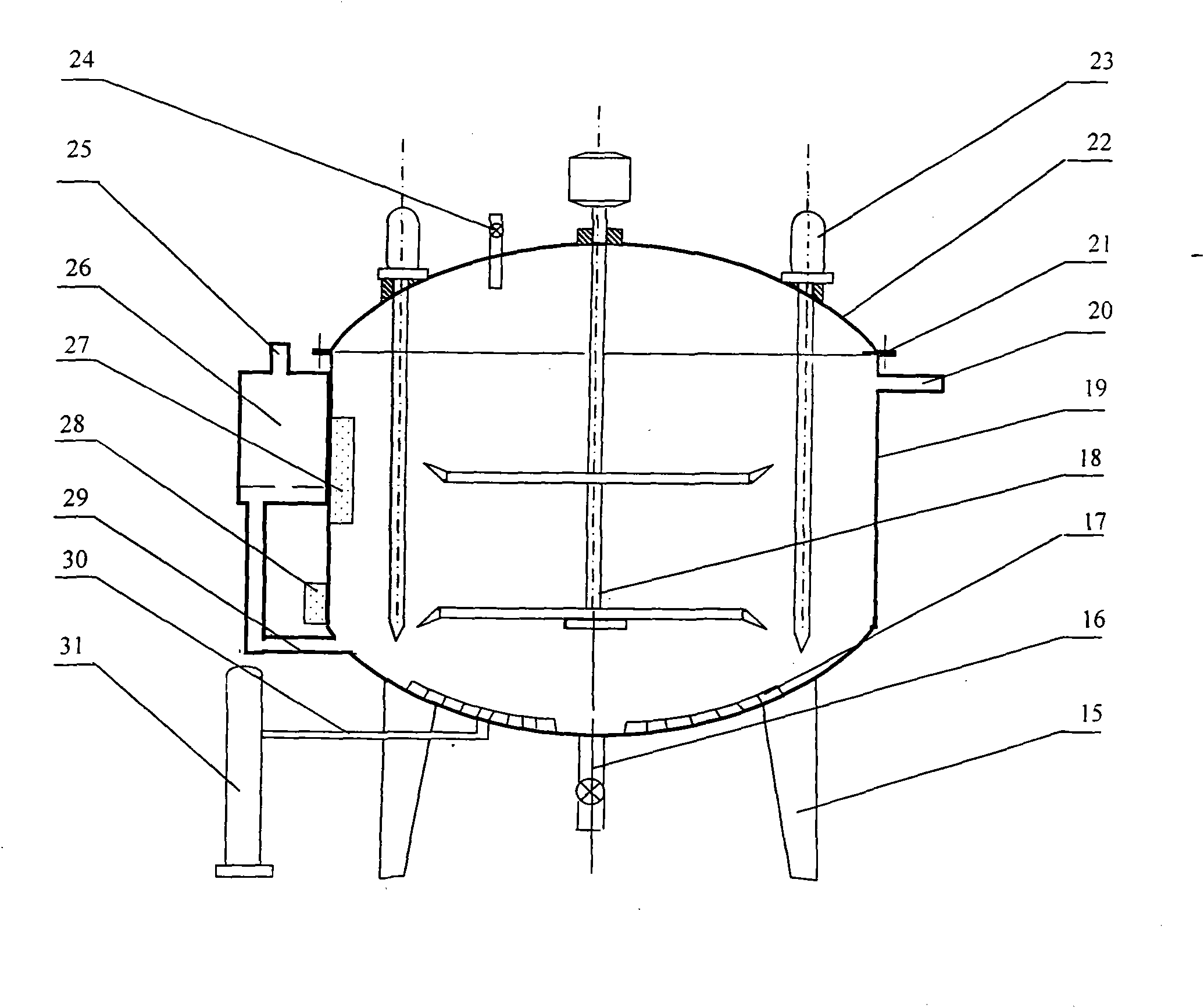

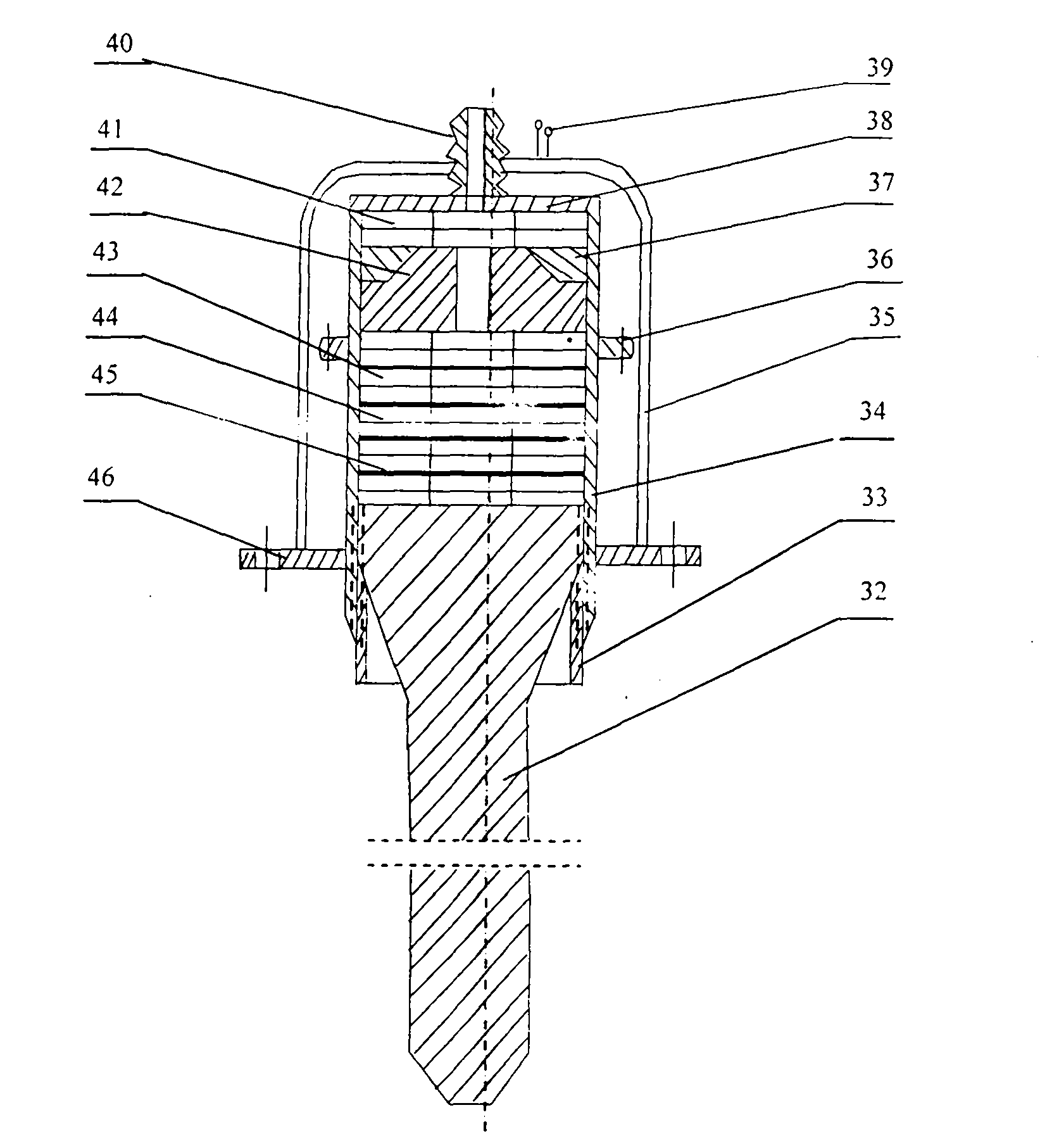

[0075] The power ultrasonic cavitation degradation high-concentration organic wastewater pretreatment technology and equipment of the present invention include: an organic wastewater regulating tank, a flow type power ultrasonic cavitation degradation reactor, and an automatic control device. The water inlet pipe (13) of the organic wastewater regulating tank is connected with the concentrated drainage pipe for collecting high-concentration organic wastewater in the existing sewage treatment system; the water outlet pipe (20) of the flow type power ultrasonic cavitation degradation reactor is connected with the existing sewage The high-concentration organic wastewater in the treatment system is connected to the water inlet pipe.

[0076] as attached figure 1 As shown, the organic wastewater regulating tank is designed as a tank-type fully enclosed structure as a whole; it is composed of a tank cover (6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com