Roller compacted concrete dam and slit forming method thereof

A technology for rolling concrete and forming joints is applied in the field of rolling compacted concrete dam body and joint forming, and rolling concrete arch dam forming joints. , The effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

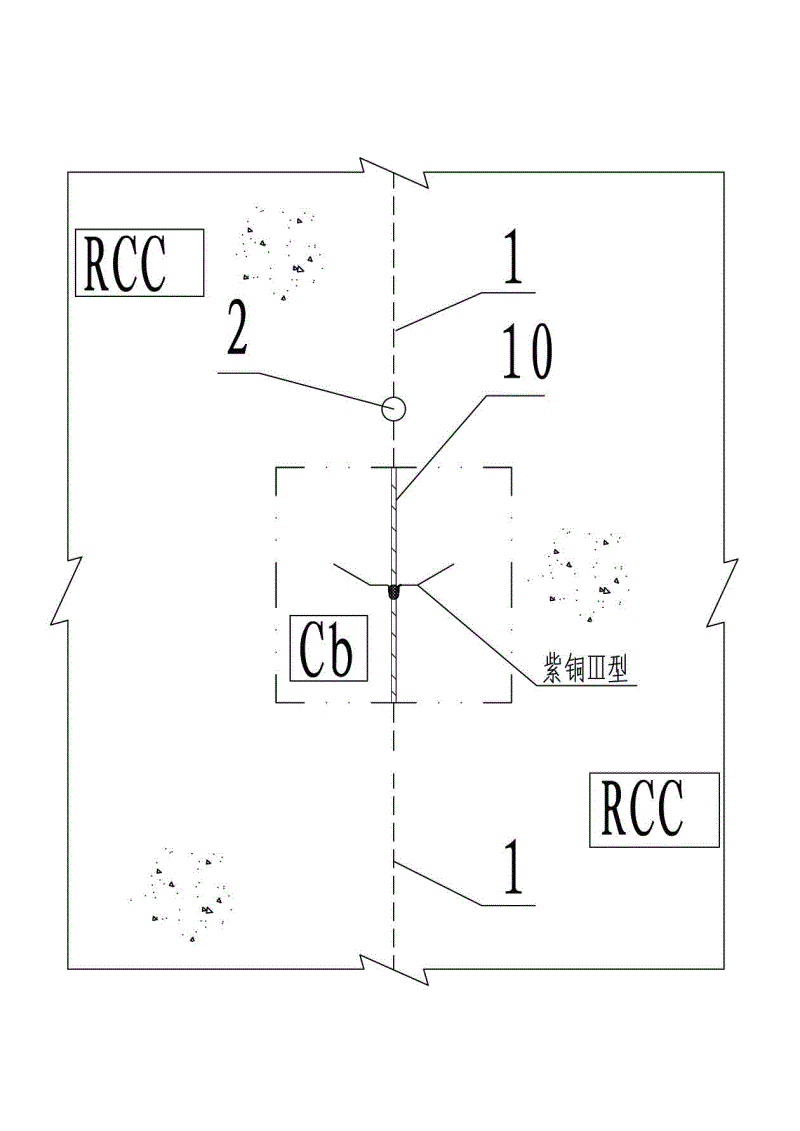

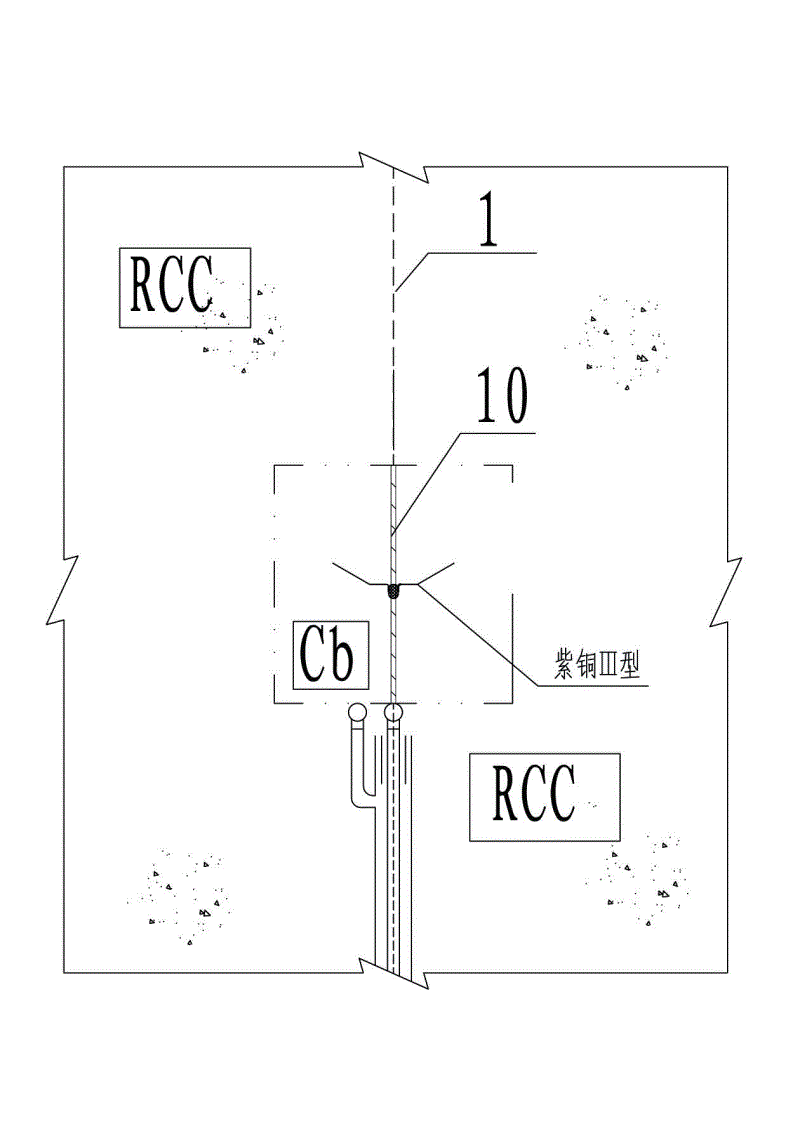

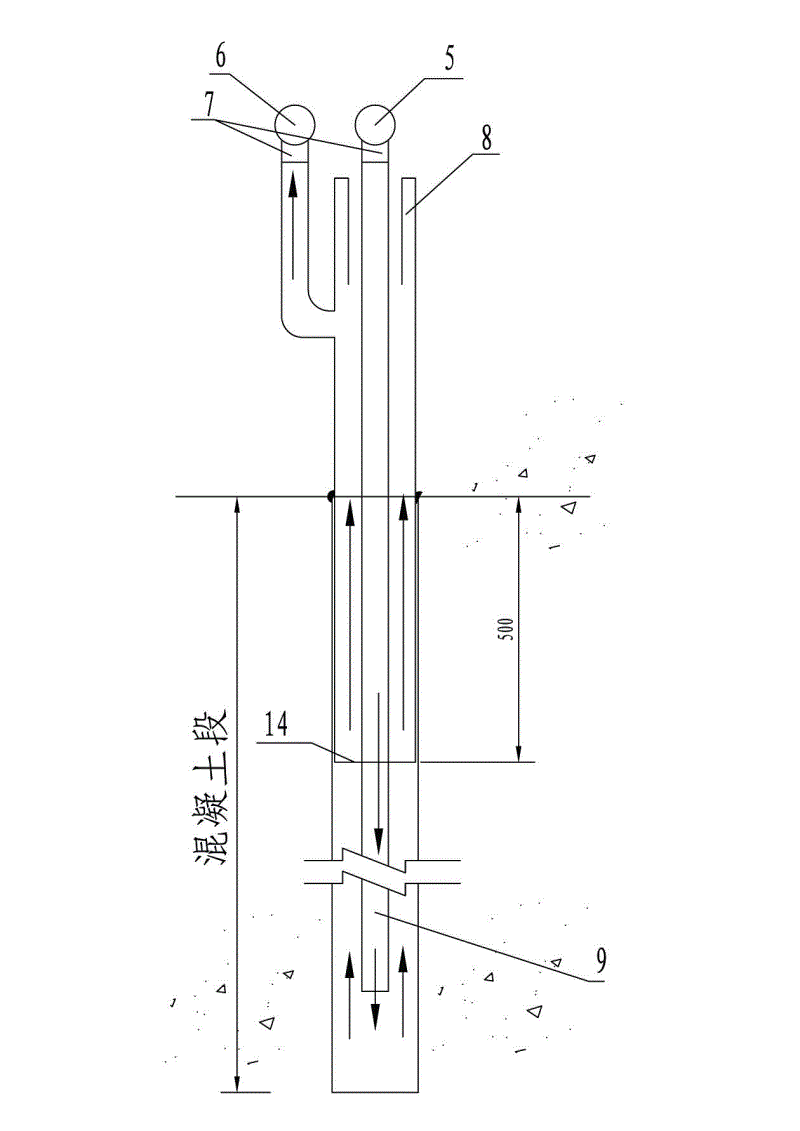

[0027] Such as figure 1 and 2 As shown, the distance between the induction holes 2 constructed along the transverse joint 1 is 0.75m, and the hole diameter is φ91; Asphalt hemp silk; a complete horizontal joint 1 irrigation area is about 30m long and 10m high; the diameter of the slurry feeding main pipe 5 and the slurry returning main pipe 6 are preferably 50mm, and the diameter of the slurry feeding branch pipe and the slurry returning branch pipe is preferably 33mm. The distance from the bottom of the induction hole is not more than 0.2m; the grouting system casing 14 is inserted 0.5m below the concrete silo surface, and the space between the grouting system casing 14 and the concrete induction hole is blocked with cotton yarn to avoid grout leakage; the grouting branch pipe is inserted into the grouting system casing In 14, the pipe wall gap between the main pipe 5 and the casing pipe 14 of the grouting system is sealed with a rubber plug 8.

[0028] Such as image 3 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com