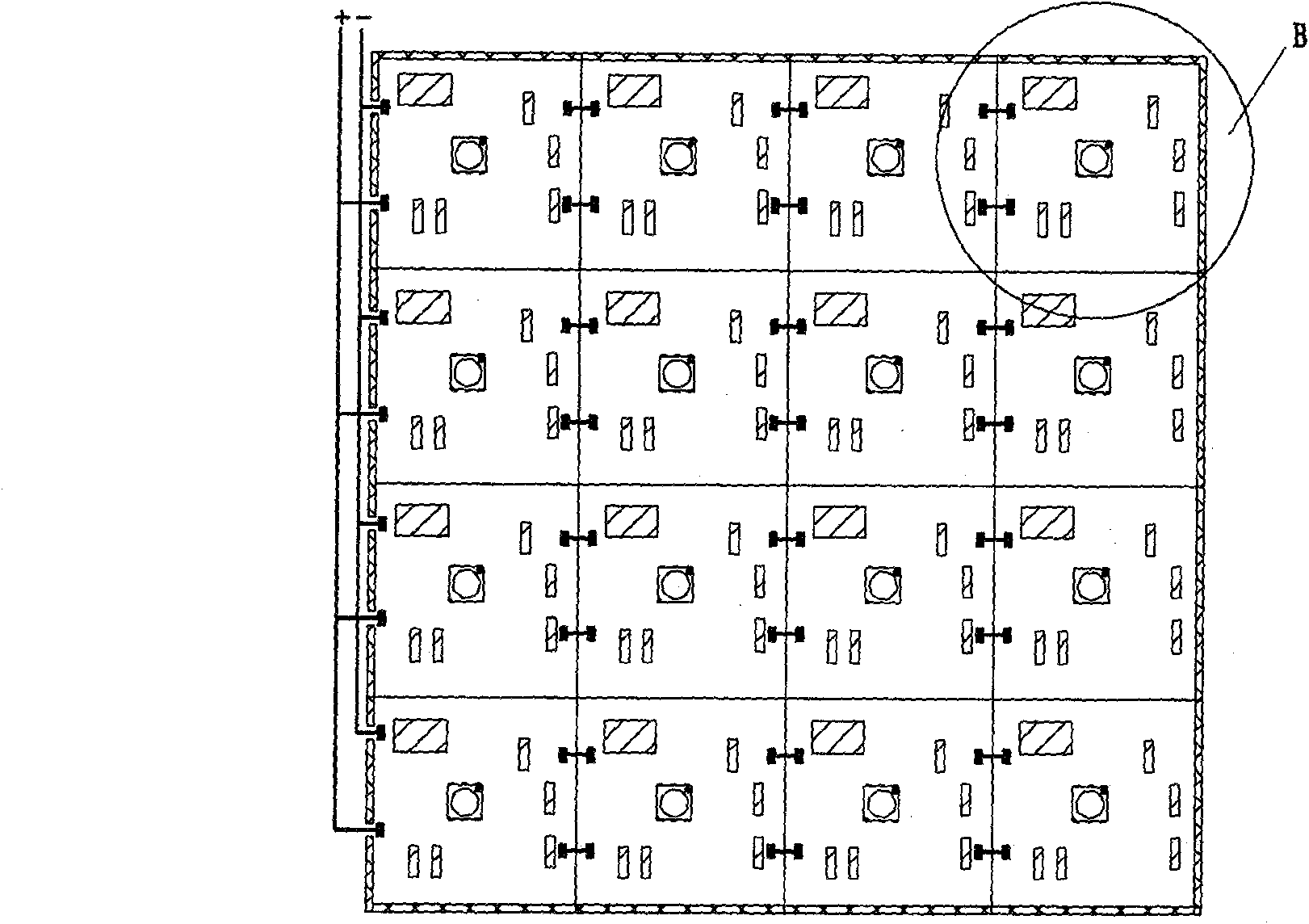

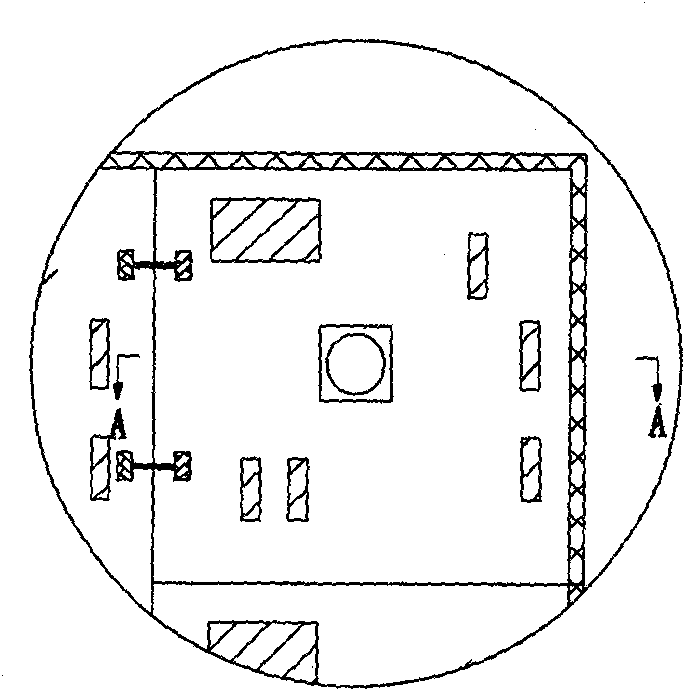

Ultrathin LED light source plate and packaging method thereof

A technology of LED light source and packaging method, applied in the direction of light source fixing, lighting device, lighting device parts, etc., can solve the problems of easy foaming, thick light source board thickness, reliability problems, etc., and achieves high reliability and weight. Light and thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

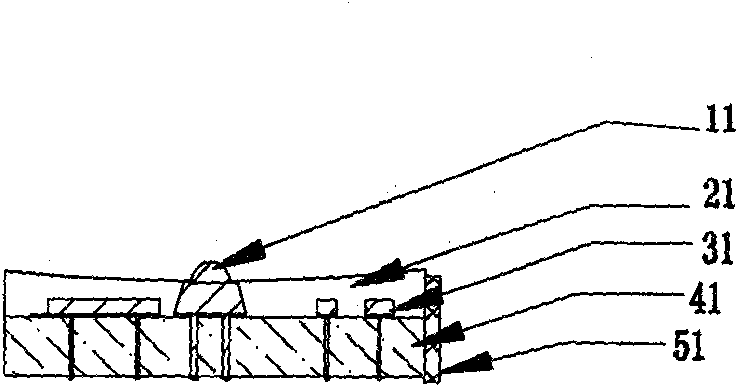

[0034] The encapsulation method is as follows:

[0035] Design circuit on circuit board - circuit board cleaning - solder paste coating at soldering point - patching of electronic components such as resistors - LED light source patching - circuit board cleaning - reflow soldering - testing - laying EVA film - laying cover plate - lamination - trimming - curing - testing.

Embodiment 2

[0037] If the LED light source uses thermal paste as the heat dissipation connection, the packaging method includes the following steps:

[0038] Design circuit on the circuit board-circuit board cleaning-solder paste coating at soldering point-resistor and other electronic components placement-circuit board cleaning-reflow soldering-coating thermal paste-LED light source placement-LED light source positive and negative welding-test - Laying of EVA film - Laying of cover - Lamination - Trimming - Curing - Testing.

Embodiment 3

[0040] If plug-in electronic components and LED light sources are used, the packaging method includes the following steps:

[0041] Design jacks and circuits on the circuit board-circuit board cleaning-resistor and other electronic components plug-in and welding-LED light source plug-in and welding-circuit board cleaning-testing-laying EVA film-laying cover board-lamination-cutting-curing -test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com