Embedded type multipoint wireless temperature measurement method of guide screw

A wireless temperature measurement, built-in technology, applied in thermometers, measuring devices, measuring heat, etc., can solve inaccurate problems, achieve remote transmission, improve processing accuracy, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

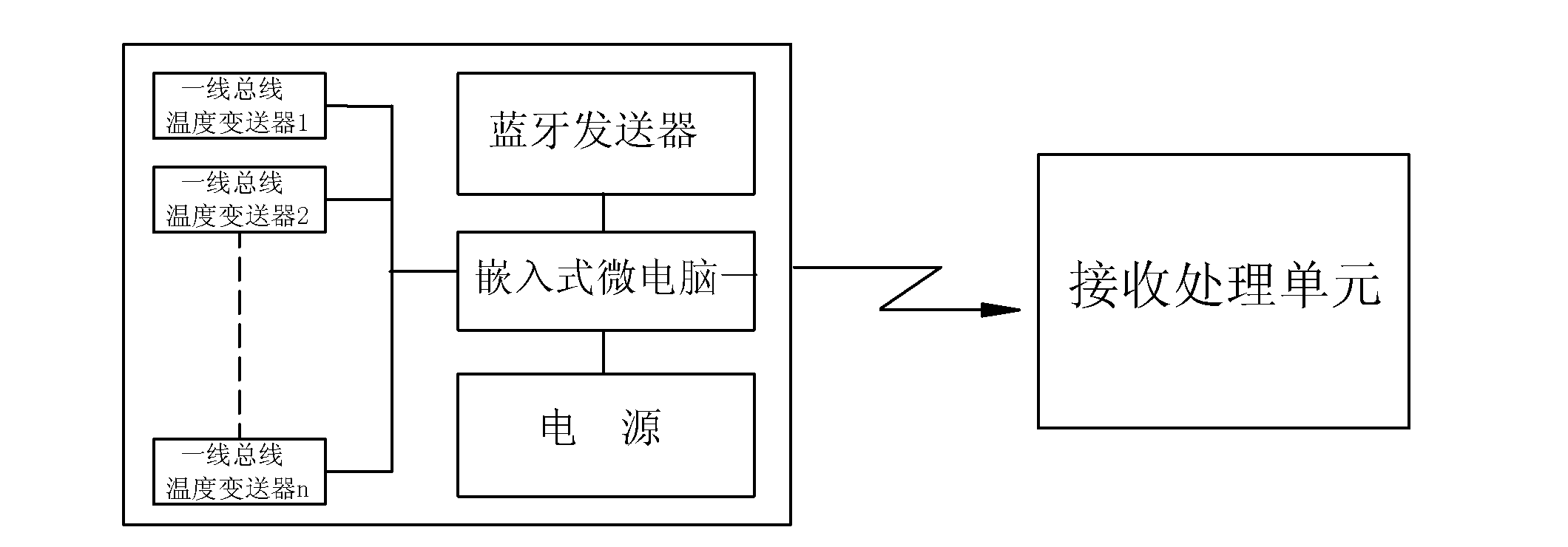

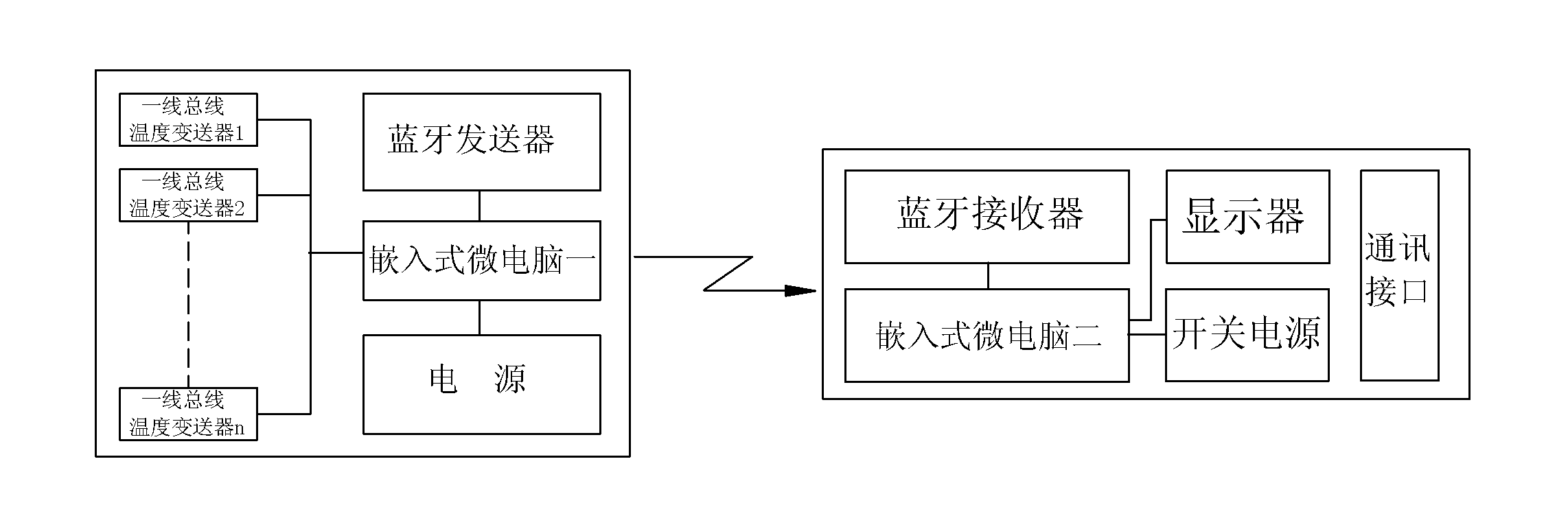

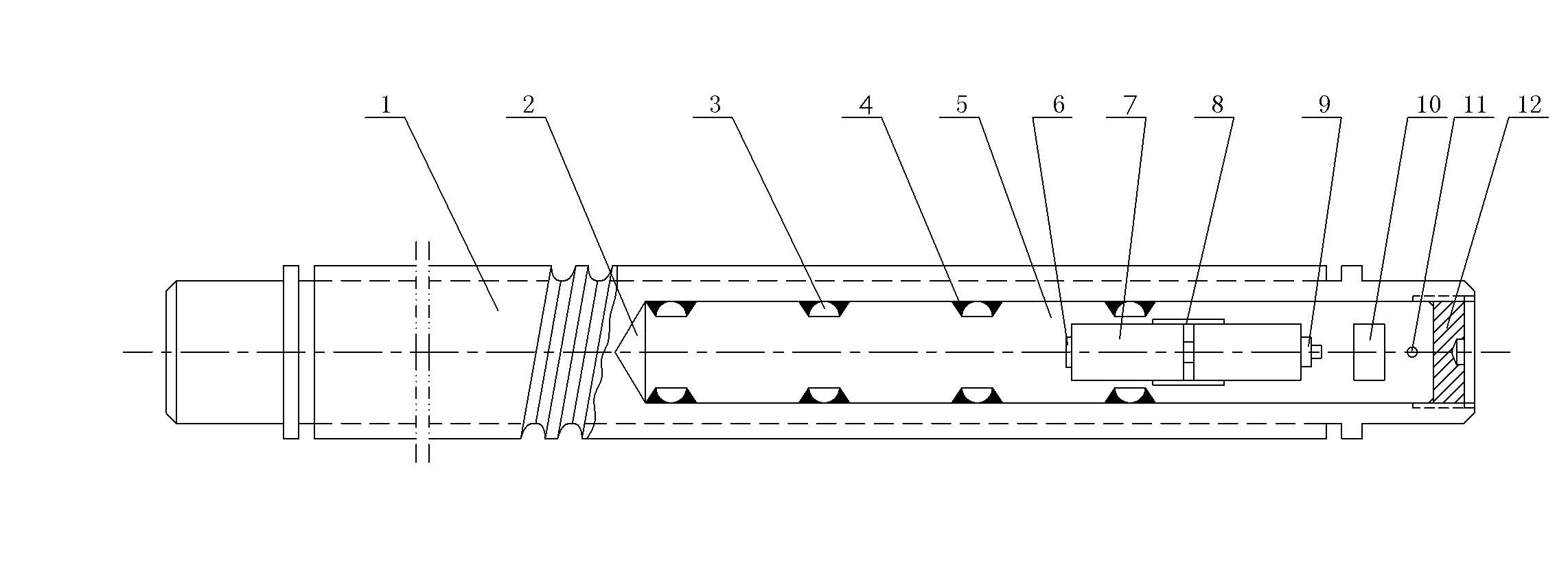

[0019] See figure 1 , figure 2 , image 3 , a lead screw embedded multi-point wireless temperature measuring device, a wireless temperature measuring device is embedded inside the lead screw 1, the wireless temperature measuring device is composed of a temperature transmitter, a Bluetooth transmitter, and an embedded microcomputer, which can be made into Printed circuit board 5, power supply adopts lithium battery 7. The temperature transmitter 3 is multi-point distributed on the inner wall of the screw 1 in the length direction and is close to the inner wall of the screw, and the surroundings of the temperature transmitter 3 are filled with heat-conducting silicone grease 3; the Bluetooth transmitter and the Bluetooth receiver of the receiving processing unit realize wireless communication. communication. See fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com