Roll-to-roll continuous thin film PV manufacturing process and equipment with real time online IV measurement

A process and film technology, applied in the field of roll-to-roll continuous film PV manufacturing process and equipment with real-time online IV measurement, can solve the problems of reduced efficiency, increased manufacturing cost, poor film quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

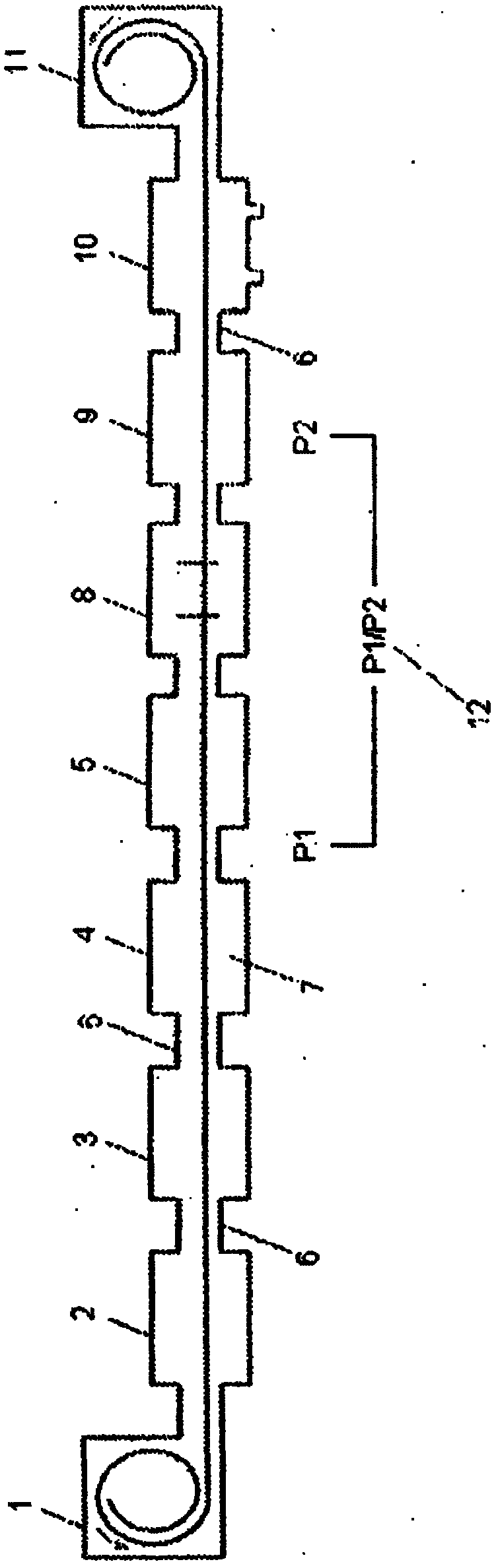

[0065] Figure 6 A DPIU 500 is shown that includes a pumping section 503 in fluid communication with a first PIU 501 and a second PIU 502 . A port of the first PIU 501 is connected to a first deposition space 507 , and a second port of the PIU 501 is connected to the pumping section 503 . A port of the second PIU 502 is connected to a second deposition space 508 , and a second port of the PIU 502 is connected to the pumping section 503 . The pressure in the first deposition space 507 closest to the first PIU 501 is 'P1'. The pressure in the second deposition space 508 closest to the second PIU 502 is 'P4'. The pressure closest to the first PIU 501 in the pumping interval 503 is 'P2'. The pressure closest to the second PIU 502 in the pump down section 403 is 'P3'. A first purge gas (for example, H 2 ) is provided to the first PIU 501. A second purge gas (eg, Ar) enters the second PIU 502 through the gas inlet 506 . The first and second purge gases are removed from the pu...

example 2

[0066] Multiple roll-to-roll deposition systems are available to form Figure 7 of photovoltaic cells. The large-scale thin-film silicon solar cell production line in the front-end facility includes a roll-to-roll processing machine (not shown), a back reflector roll-to-roll production machine ( Figure 8 ) and a PECVD / ITO roll-to-roll production machine ( Figure 9 ). A coil of stainless steel (SS) was used as the substrate, which in some embodiments may have a thickness of 0.005" (0.127 mm), a minimum width of 10", a preferred width of 36", and a minimum length of 5000 ft.

[0067] In this roll-to-roll processing machine, a roll of uncleaned SS sheet substrate loaded at the in-load (roll-off) chamber is directed through a detergent tank, a DI water Rinsing tank, a blower and drying station. An oil-free, particle-free clean SS substrate sheet is then wound onto a spool core at the rewind (winding) chamber of the processing machine along with a protective interleaf layer ...

example 3

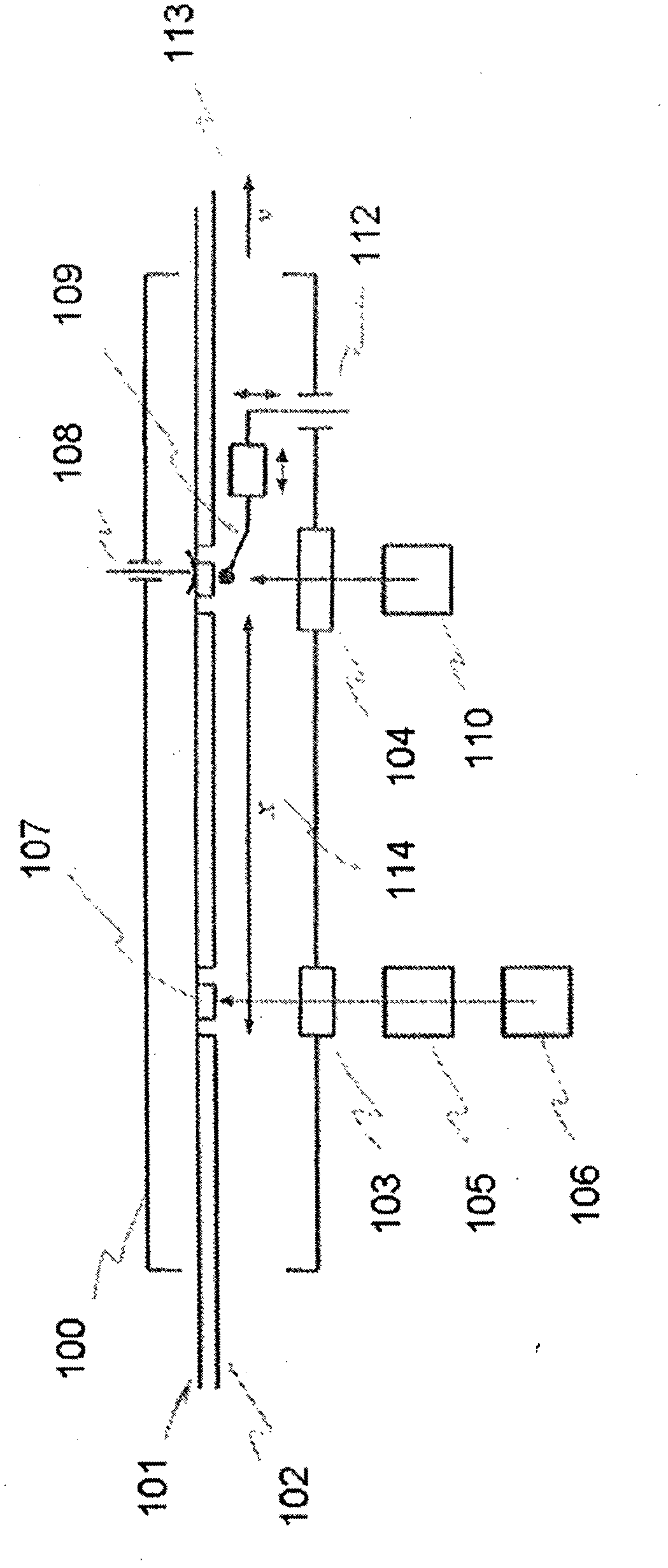

[0070] refer to Figure 10 , a vacuum roll-to-roll film production machine can be used to form Figure 7 of photovoltaic cells. This roll-to-roll production machine, shown in two sections to fit the page, can be a single, continuous roll-to-roll system. A roll-to-roll production machine for large-scale thin-film silicon solar cells in a front-end facility includes a substrate loading chamber, a plasma cleaning chamber, a back reflector sputter deposition chamber, a thin-film silicon PECVD deposition chamber, a A transparent conductive film vacuum deposition chamber and a substrate rewinding chamber. A gas pressure differential process isolation unit (DPIU) is disposed between the back reflector deposition chamber and the PECVD chamber. A second DPIU is disposed between the PECVD chamber and the transparent conductive film deposition chamber. A stainless steel (SS) coil was used as the substrate with a thickness of about 0.005" (0.127 mm), a minimum width of about 10", a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com