Specially-shaped extruding female die of aluminium alloy seamless gas cylinder

A technology of seamless gas cylinders and aluminum alloys, applied in the direction of metal extrusion dies, etc., can solve the problems of reducing processing procedures, achieve the effects of reducing metal volume, reducing metal thickness, and reducing product processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

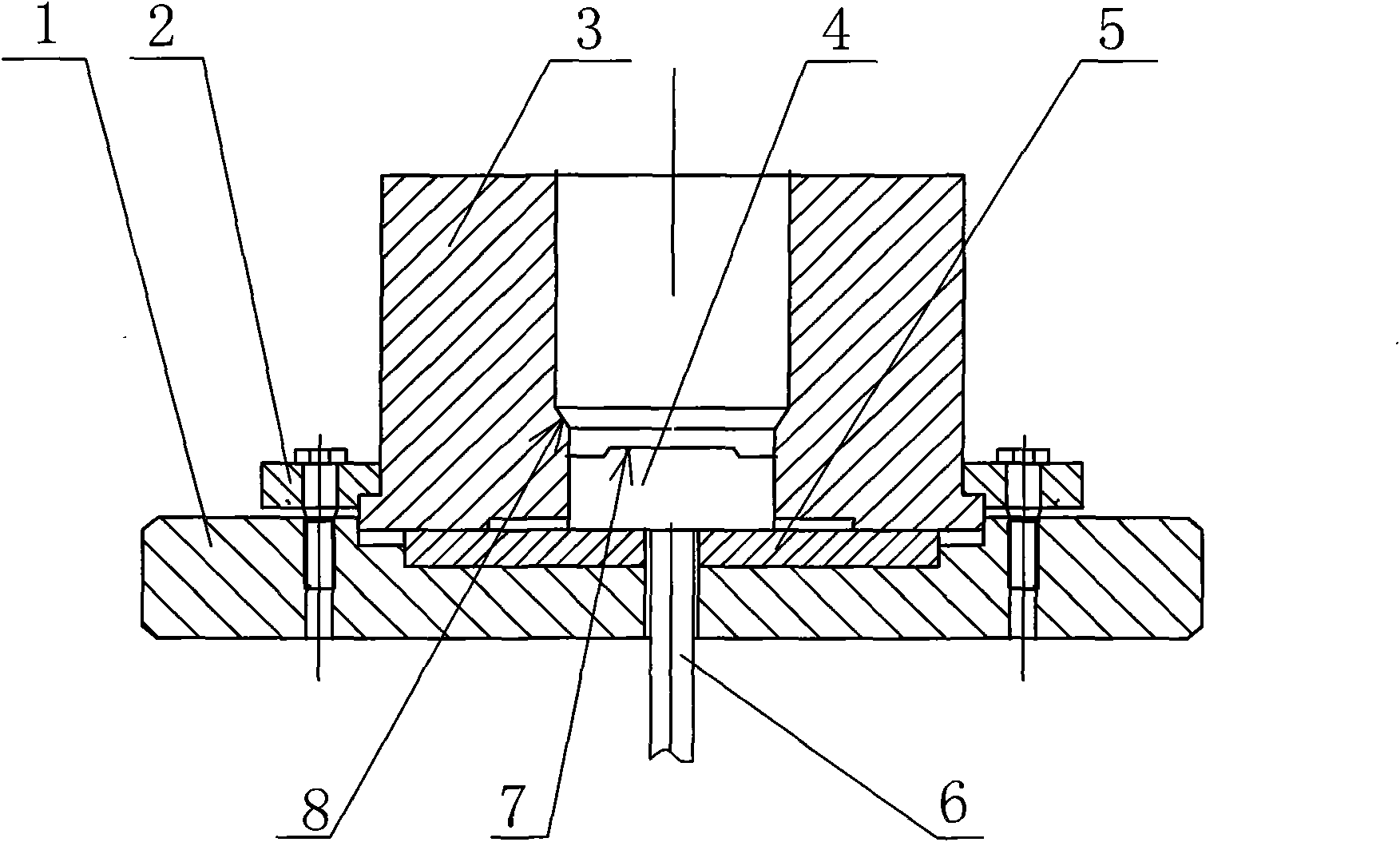

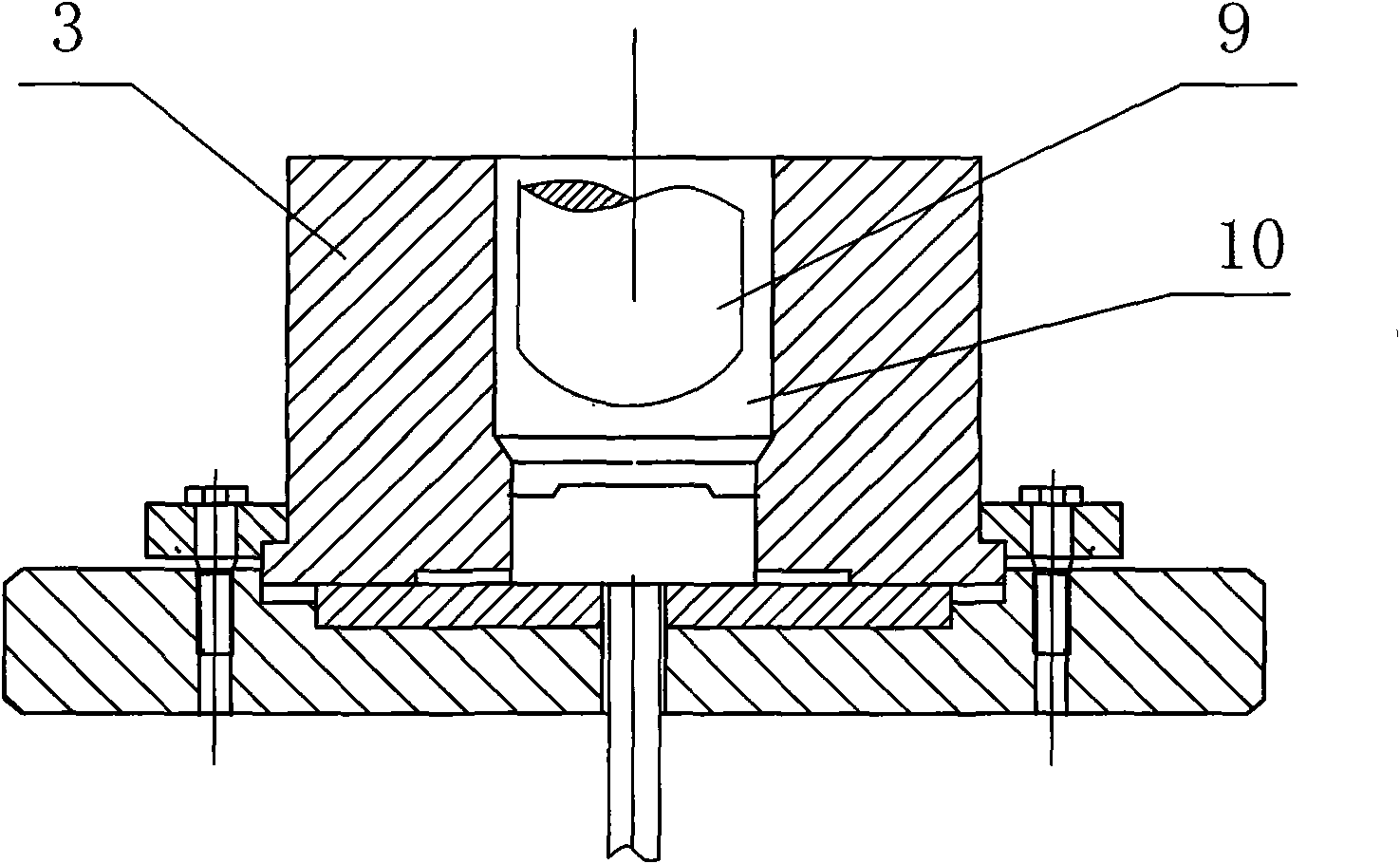

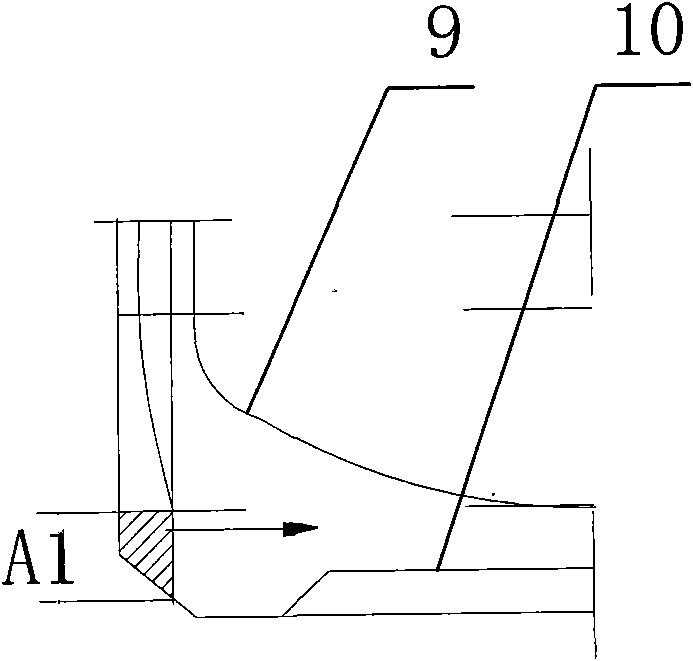

[0012] The present invention draws the following conclusions after analyzing the metal flow direction involved in the deformation during the drawing deformation process: the bottom and side walls of the cup body 10 are under the joint action of the drawing punch 9 and the drawing die. The changes of necking and wall reduction mainly occur, that is, after the cup body is drawn, the outer surface diameter and wall thickness of the cup body are reduced. For the convenience of description, the metal participating in the deformation during the drawing process is divided into three parts A1, A2, and A3 according to the position of the design shape of the drawing punch. For details, see image 3 , Figure 4 , Figure 5 the shaded part. During the drawing process, the cup body is under the action of the drawing punch, and the metals in the three parts A1, A2, and A3 enter the drawing die in turn. We analyze the metal flow direction of each part as follows: First, if image 3 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com