Boron aluminate luminescent material capable of generating green light and preparation method thereof

A technology of boroaluminate and luminescent materials, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve problems such as long afterglow time, unfavorable dynamic picture display, and decreased luminous intensity, so as to achieve uniform and sufficient reaction and overcome excessive afterglow time. Longer, the effect of lowering the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of Sr 0.76 Gd 0.02 Tb 0.1 Na 0.12 al 3 BO 7 Boroaluminate green luminescent material

[0031] Weigh strontium carbonate SrCO 3 0.5610g, aluminum hydroxide Al(OH) 3 1.1701g, sodium carbonate Na 2 CO3 0.0319g, boric acid H 3 BO 3 0.3092g, terbium oxide Tb 4 o 7 0.0935g, gadolinium oxide Gd 2 o 3 0.0181 g and flux (5%) boric acid H 3 BO 3 0.1092g. After fully grinding all the materials in an agate mortar, put them into a corundum crucible for pre-sintering at 600°C for 2h, then cool to room temperature, and grind again thoroughly. Finally, the reground product was calcined at 1000°C for 5 hours, cooled to room temperature, and Sr 0.76 Gd 0.02 Tb 0.1 Na 0.12 Al 3 BO 7 Boroaluminate green luminescent material.

Embodiment 2

[0032] Example 2 Preparation of Sr 0.76 Gd 0.02 Tb 0.1 Li 0.12 Al 3 BO 7 Boroaluminate green luminescent material

[0033] Weigh strontium carbonate SrCO 3 0.5610g, aluminum hydroxide Al(OH) 3 1.1701g, lithium carbonate Li 2 CO 3 0.0222g, boric acid H 3 BO 3 0.3092g, terbium oxide Tb 4 o 7 0.0935g, gadolinium oxide Gd 2 o 3 0.0181 g and flux (5%) boric acid H 3 BO 3 0.1087g. After fully grinding all the materials in an agate mortar, put them into a corundum crucible for pre-sintering at 600°C for 2h, then cool to room temperature, and grind again thoroughly. Finally, the reground product was calcined at 1000°C for 5 hours, cooled to room temperature, and Sr 0.76 Gd 0.02 Tb 0.1 Li 0.12 Al 3 BO 7 Boroaluminate green luminescent material.

Embodiment 3

[0034] Example 3 Preparation of Sr 0.76 Gd 0.02 Tb 0.1 K 0.12 Al 3 BO 7 Boroaluminate green luminescent material

[0035] Weigh strontium carbonate SrCO 3 0.5610g, aluminum hydroxide Al(OH) 3 1.1701g, potassium carbonate K 2 CO 3 0.0415g, boric acid H 3 BO 3 0.3092g, terbium oxide Tb 4 o 7 0.0935g, gadolinium oxide Gd 2 o 3 0.0181 g and flux (5%) boric acid H 3 BO 3 0.1097g. After fully grinding all the materials in an agate mortar, put them into a corundum crucible for pre-sintering at 600°C for 2h, then cool to room temperature, and grind again thoroughly. Finally, the reground product was calcined at 1000°C for 5 hours, cooled to room temperature, and Sr 0.76 Gd 0.02 Tb 0.1 K 0.12 Al 3 BO 7 Boroaluminate green luminescent material.

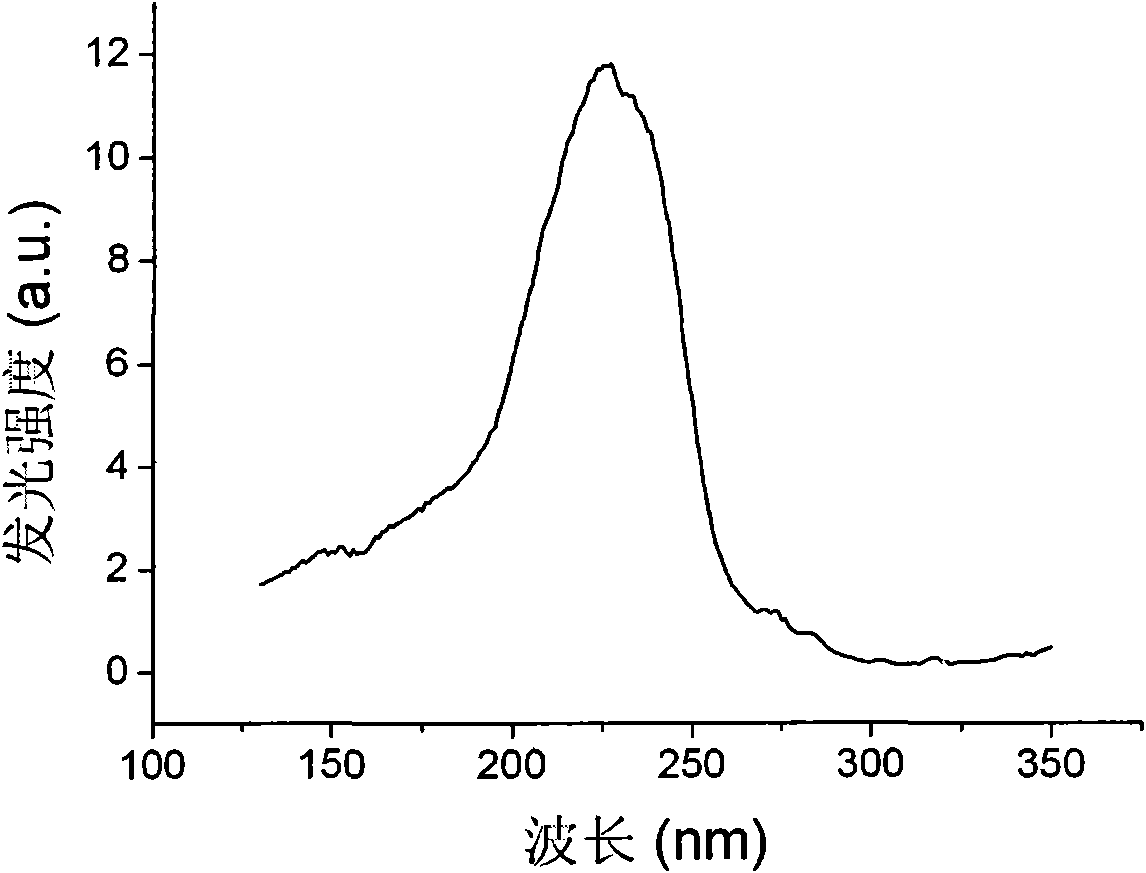

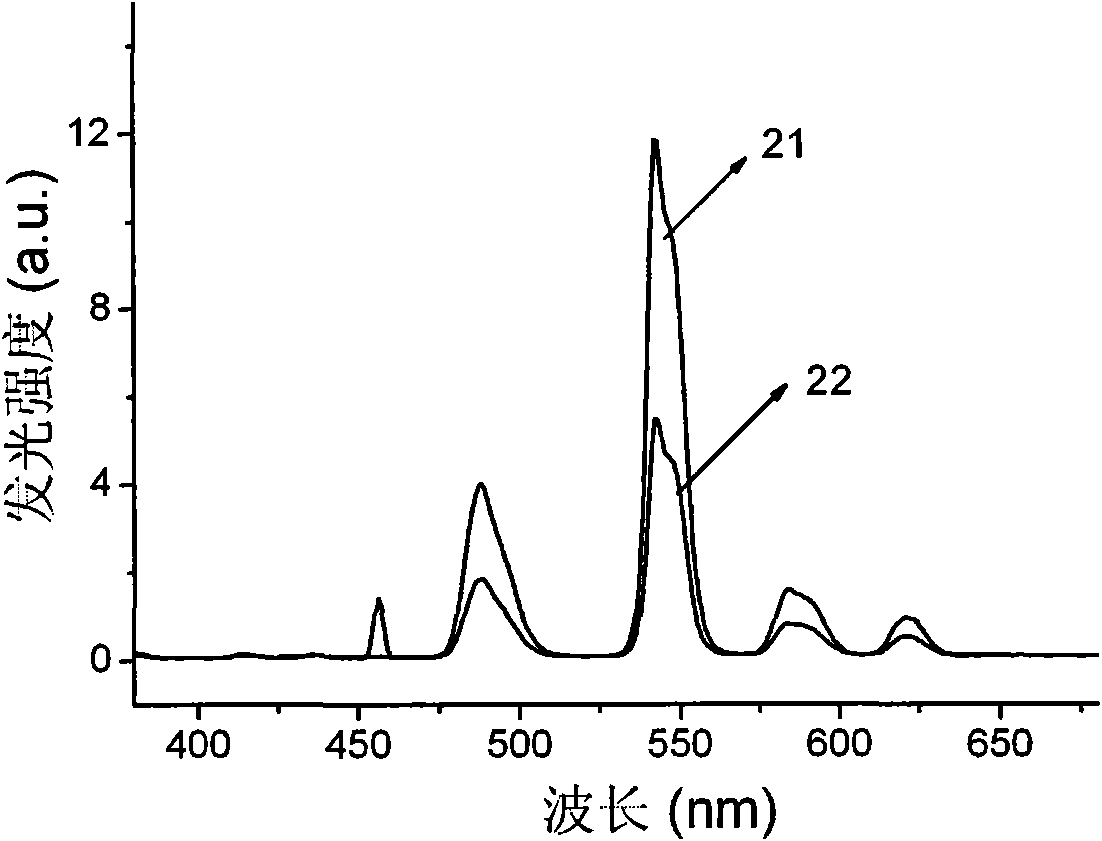

[0036] figure 1 Is the Sr prepared in this example 0.76 Gd 0.02 Tb 0.1 K 0.12 Al 3 BO 7 The excitation spectrum of the boroaluminate green luminescent material, the monitoring wavelength is 543nm. figure 2 It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com