Ground and underground three-dimensional extraction system of coal seam gas

A coalbed methane and surface technology, which is applied in the direction of mining fluid, mining equipment, earthwork drilling, etc., can solve the problems of pipeline blockage or leakage, mine safety threats, short extraction cycle, low production capacity, etc., and achieve low construction risk and difficulty , mature technology and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

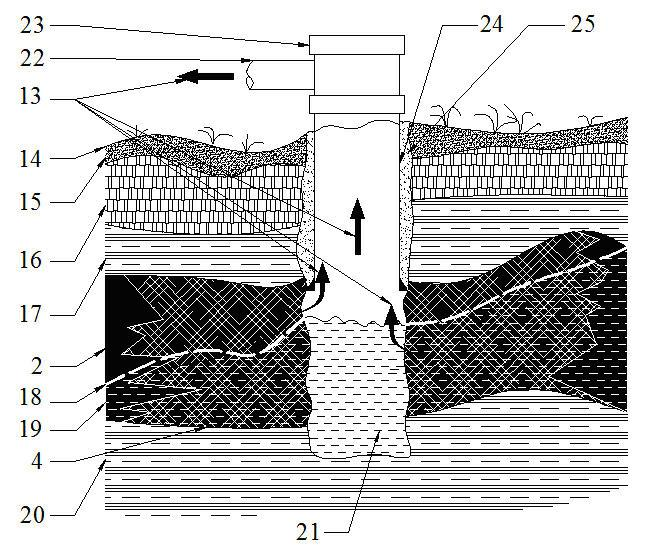

[0034] 1. First construct the shaft 5 from the ground to the target coal seam 2, and penetrate into the bottom plate rock layer 20 of the coal seam 2. During the construction of the shaft 5, the casing 24 is run in according to the design, and the well is cemented with the cement 25; the target coal seam 2 is fractured to form the coal seam fracturing area 4; the wellhead 23 and the coalbed methane surface collection pipeline 22 are installed, and the Coal bed methane recovery13.

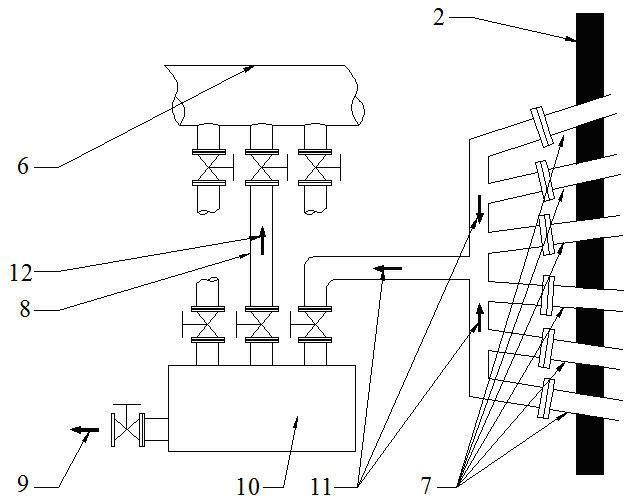

[0035] 2. Construct the near-horizontal cluster drilling group 3 in the underground target coal seam in sequence according to the design. During the construction, ensure that the drilling group and the fracturing area 4 are connected; install the near-horizontal drilling hole connecting pipeline 7 to connect the underground main drainage pipe Road 6, drain tank 10 and orifice connection pipeline 7, begin to get rid of accumulated water and coal dust 9 in the hole.

[0036] The principle of the cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com