On-line modeling and optimizing method suitable for recovering coking coarse benzene

An optimization method, a technology of coking crude benzene, which is applied in special data processing applications, instruments, electronic digital data processing, etc., can solve the problems that the overall optimization of crude benzene production cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

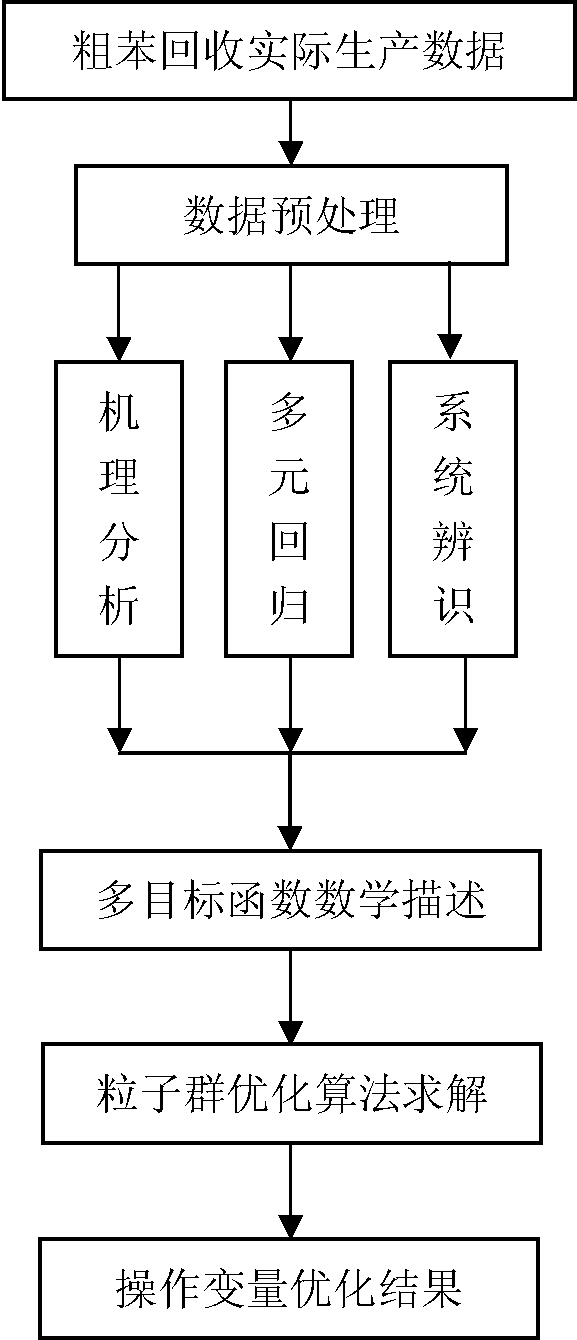

[0138] The method and system of the present invention will be described in detail below in conjunction with the accompanying drawings. The flow chart of the on-line modeling and optimization method suitable for coking crude benzene recovery proposed by the present invention is attached figure 1 shown. The specific implementation steps are as follows:

[0139] 1. Modeling part

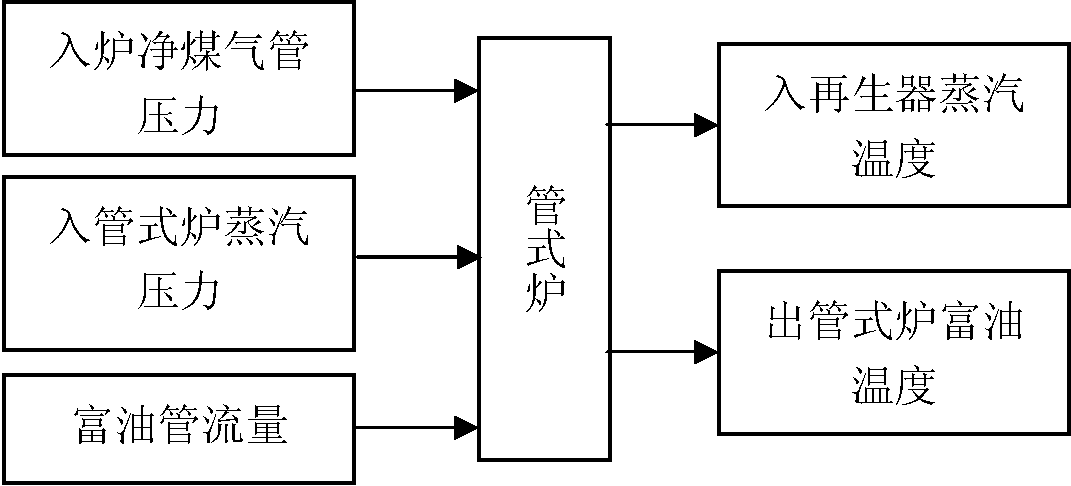

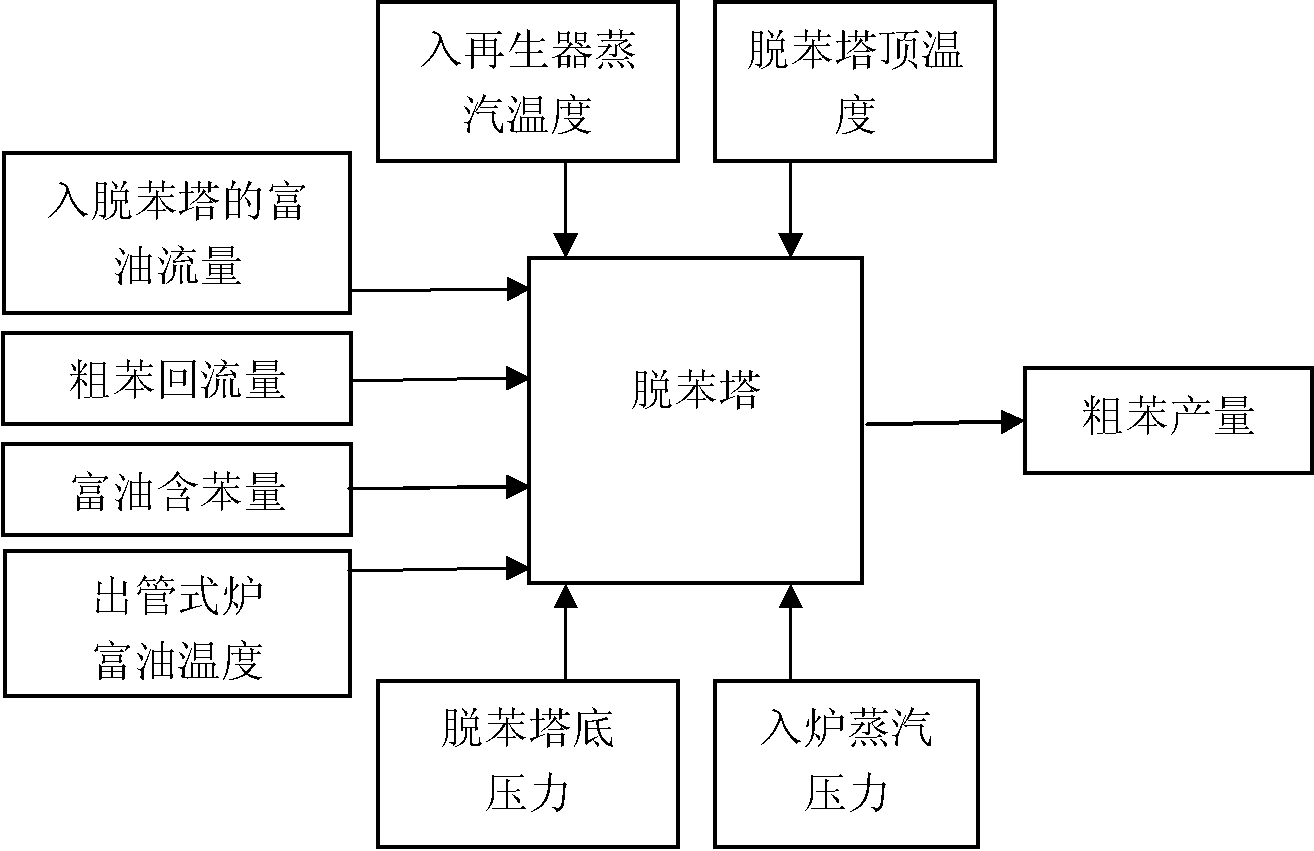

[0140] 1.1 Mechanism modeling process of benzene washing process

[0141] Benzene hydrocarbon content a(kg / m 3 ) and the benzene group content c (mass percentage) in the washing oil is expressed as:

[0142] c = 2.24 * a * p 1.25 * Mm * p 0

[0143] In the formula: p 0 is the saturated vapor pressure of crude benzene at the recovery temperature. p is the tower gas pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com