Silicon-based thin film solar module and method for power station

A technology of solar cells and silicon-based thin films, applied in the field of solar cells, can solve problems such as solar cell breakage and overflow, and achieve the effects of ensuring power generation performance, increasing space, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

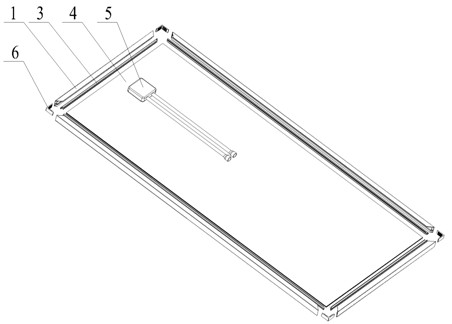

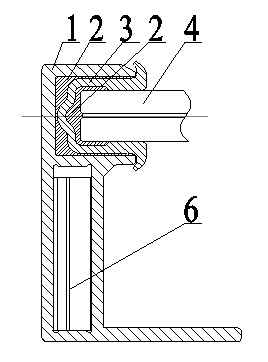

[0018] Example 1: The solar cell 4 is an amorphous silicon thin-film solar laminated glass module, using 3.2mm amorphous silicon cells + 0.6EVA + 3mm semi-tempered glass glass laminated glass, with a specification of 707×1640×6.8mm, and multiple battery components They are connected in series and parallel to each other to form a solar cell array for power stations. The battery module is composed of silicon-based thin-film solar cells, elastic parts, and frames packaged together. The elastic parts are installed in the frame of the battery module, and the end of the side wall covers the edge of the frame. , the electrode bus line of the solar battery array is connected with the charge controller, and the power is supplied by the output of the inverter. The elastic part in the frame of the battery module is an elastic rubber strip 3 made of thermoplastic rubber material. The thickness of the boss 3-5 of the elastic rubber strip 3 is 1.5 mm, and the thickness of the rear thin part ...

Embodiment 2

[0020] Example 2: The method of making a silicon-based thin-film solar cell assembly for a power station is: apply sealant around the solar cell, and insert the edge of the solar cell coated with sealant into the open groove of the inverted "several"-shaped elastic component , the inner wall of the elastic part is tightly sealed with the surface of the solar cell; the solar cell and the elastic part are installed in a frame filled with sealant, the end of the side wall of the elastic part covers the edge of the frame, and the sealant is covered with the inside of the frame The surface and the outer surface of the elastic part tightly seal and integrate the solar cell, the elastic part and the frame; the positive and negative electrodes of the solar cell are drawn out from the electrode lead-out piece.

[0021] Specifically: first place the solar cell 4 on a platform, clean the edge of the solar cell, and evenly coat an appropriate amount of silica gel 2 around the edge of the s...

Embodiment 3

[0023] Embodiment 3: The solar cell 4 of this embodiment is 3mm tempered glass+0.6mmEVA+0.52 polysilicon solar cell+0.6mmEVA+2mmPET, the glass is laminated glass, and the specification is 707×1640×6.72mm. The elastic strip 3 is thermoplastic rubber material, The thickness of the boss 3-5 is 1.5 mm, the thickness of the rear thin part 3-6 is 1 mm, the sealant 2 is silica gel, the frame 1 is an aluminum alloy frame, and the groove width is 10.4 mm. The series-parallel connection of silicon-based thin-film solar cell modules or the solar photovoltaic array is used as an independent power supply system. The DC power is generated and output to the controller to charge the battery, and the AC is output through the inverter for indoor electricity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com