Radio frequency micro electro mechanical system switch with spring plate contact and manufacturing method thereof

A micro-electromechanical system and shrapnel contact technology, which is applied to the components of TV systems, generators/motors, and the process for producing decorative surface effects, etc., can solve the problem of low melting point and hardness, increased contact resistance, and low Resistivity and other issues, to achieve the effect of simple processing method, reduce contact resistance and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment specifically describes the structural features of the RF MEMS switch provided by the technical solution of the present invention.

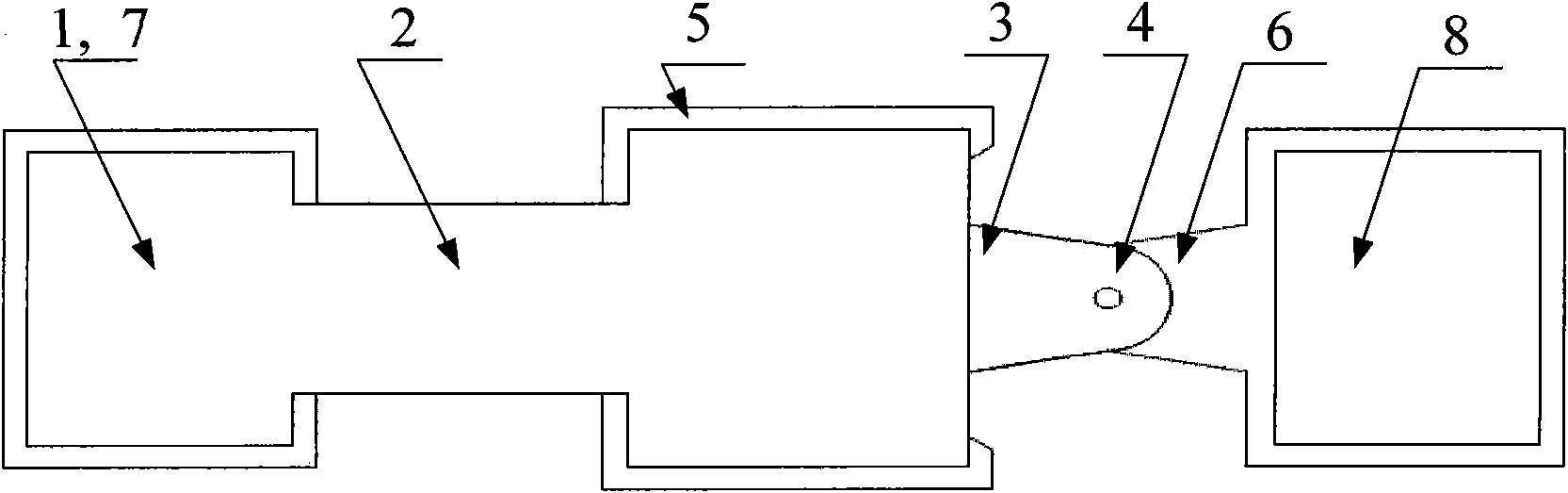

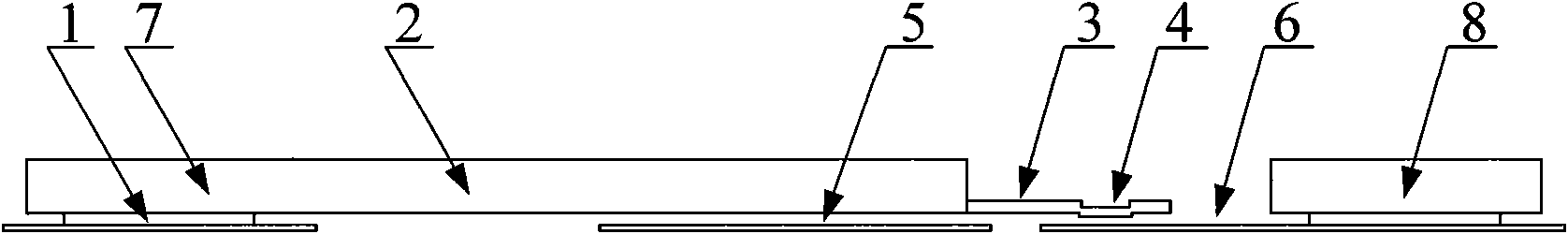

[0050] Such as figure 1 and figure 2 As shown, the RF MEMS switch includes an anchor region 1, a cantilever beam 2, and an electrostatic driving electrode 5, and the switch includes at least one set of contact devices;

[0051] The contact device includes a shrapnel contact 3, a fixed contact 6 and a concave point 4;

[0052] The shrapnel contact 3 is located above the fixed contact 6;

[0053] The concave point 4 is set on the elastic contact 3 .

[0054] The concave point 4 is used to increase the contact area between the elastic contact 3 and the fixed contact 6 .

[0055] The switch is made of all metal materials; wherein,

[0056] The shrapnel contact 3, the concave point 4 and the fixed contact 6 are made of gold, platinum group metal, platinum-gold alloy or gold-nickel alloy.

Embodiment 2

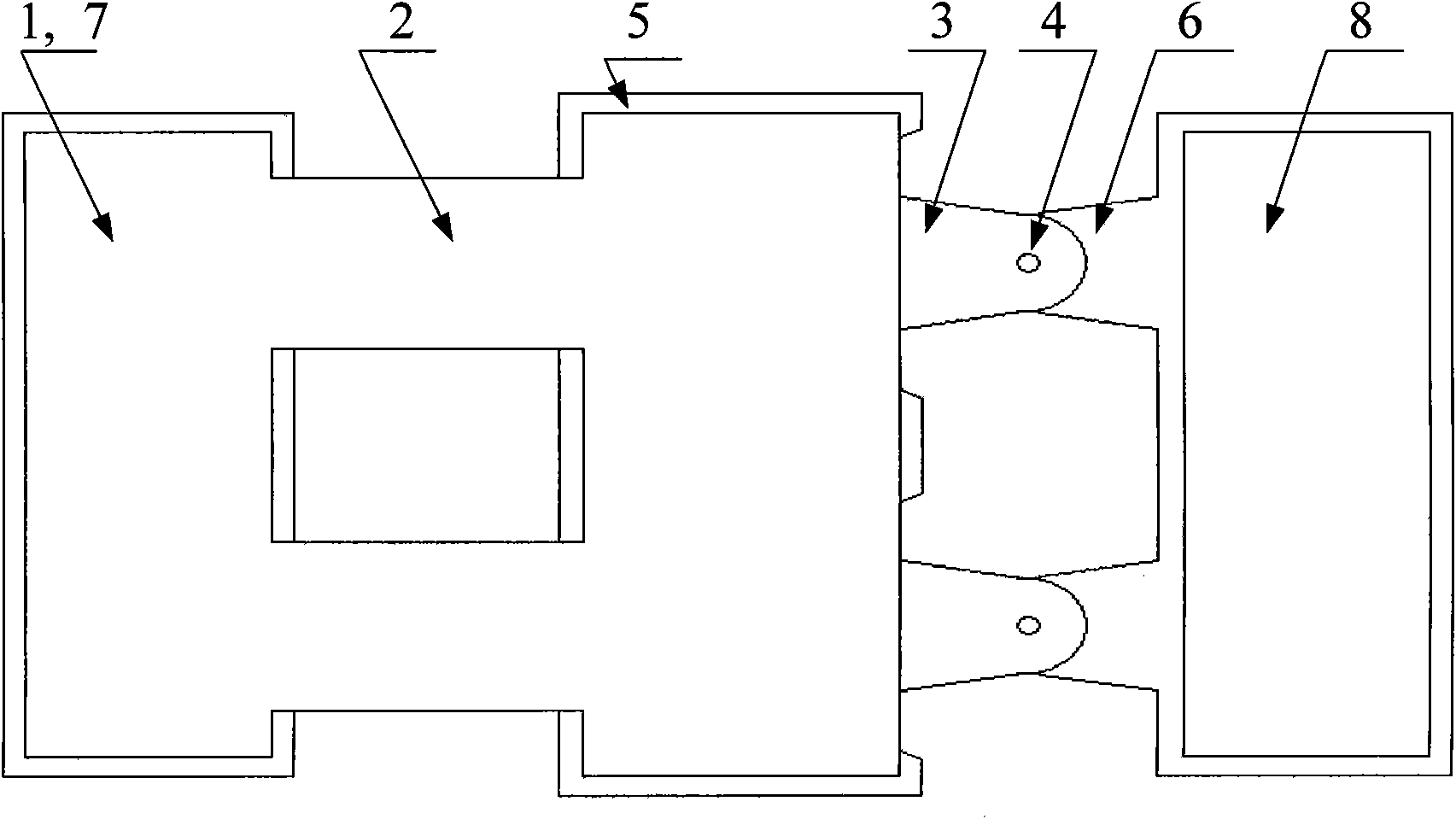

[0058] This embodiment specifically describes the structural features that the RF MEMS switch provided by the technical solution of the present invention includes two sets of contact devices.

[0059] Such as image 3 As shown, the RF MEMS switch includes an anchor region 1, a cantilever beam 2, an electrostatic driving electrode 5, and two sets of contact devices; each set of contact devices is the same as the contact device described in the foregoing embodiment 1; the two sets of contact devices The sleeve contact devices are arranged in parallel directions.

Embodiment 3

[0061] This embodiment specifically describes the structural features of the RF MEMS switch provided by the technical solution of the present invention including four sets of contact devices.

[0062] Such as Figure 4 As shown, the RF MEMS switch includes an anchor region 1, a cantilever beam 2, an electrostatic drive electrode 5, and four sets of contact devices; each set of contact devices is the same as the contact device described in the foregoing embodiment 1; the four The sleeve contact devices are arranged in parallel directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com