Device and method for monitoring abnormal state of light-emitting diode

A light-emitting diode, abnormal state technology, applied in lighting devices, light sources, electric light sources, etc., can solve problems such as increased use costs, inability to guarantee photosensitive devices, failure detection, etc., to facilitate maintenance and replacement, ensure curing quality, and ensure normal effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] When monitoring the state of a light-emitting diode, the implementation technical solution of the present invention adopts the following settings.

[0030] The set monitoring device includes a circuit module; a first reference voltage source, which generates a first reference voltage VL, as the low threshold VL of the light-emitting diode operating voltage; a second reference voltage source, which generates a second reference voltage VH, as a light-emitting diode A high threshold VH of the working voltage; wherein, both the low threshold VL and the high threshold VH of the light emitting diode working voltage are transmitted to the circuit module.

[0031] The circuit module of the present invention includes: a subtractor, which is connected in parallel at both ends of the light-emitting diode, and is used to generate the working voltage VF of the light-emitting diode; the subtractor is connected with a first comparator and a second comparator, wherein the first A compa...

Embodiment 2

[0034] In the case of multiple light emitting diodes on the circuit, the present invention also provides a device for monitoring the abnormal state of each light emitting diode. Referring now to the accompanying drawings, the specific structural features of this embodiment will be described in detail.

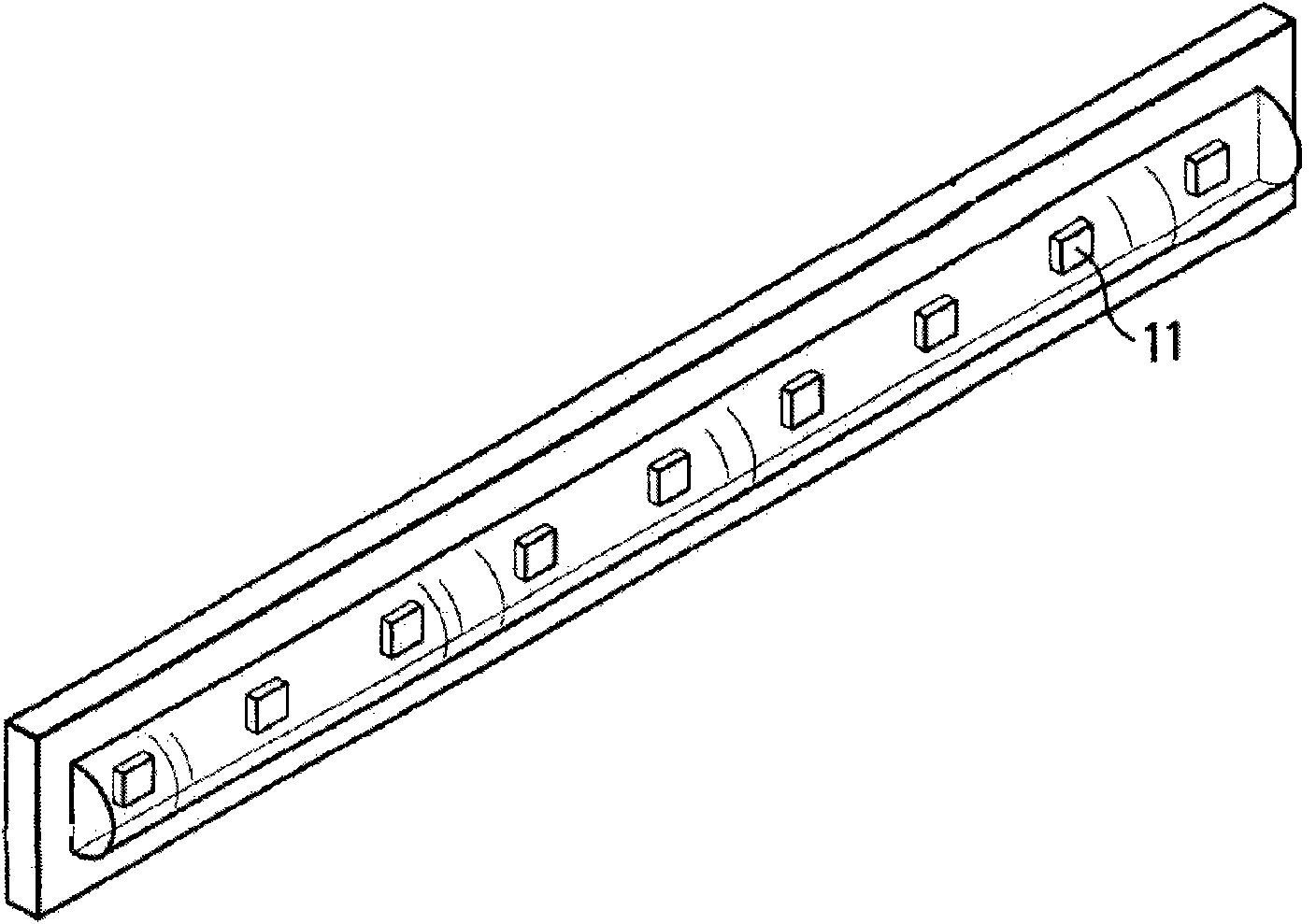

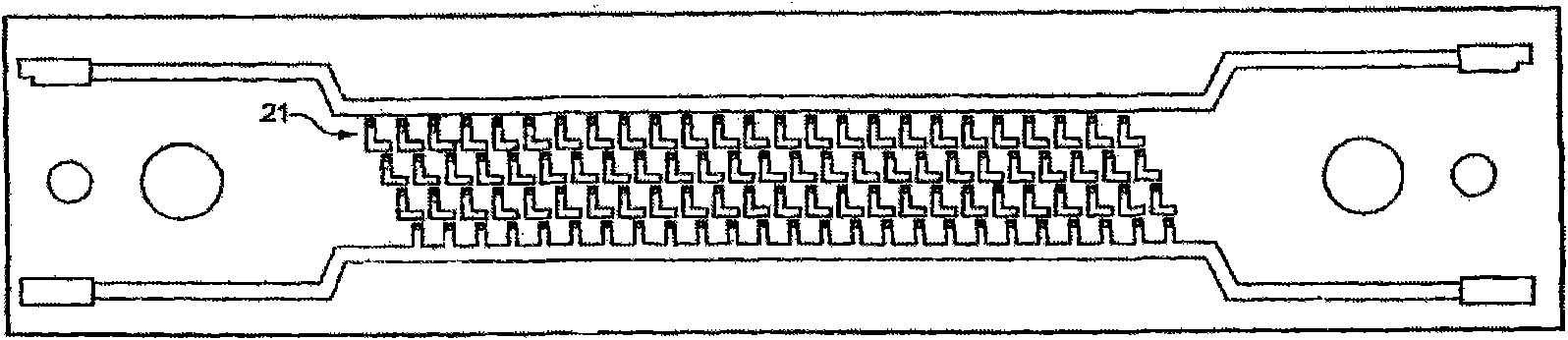

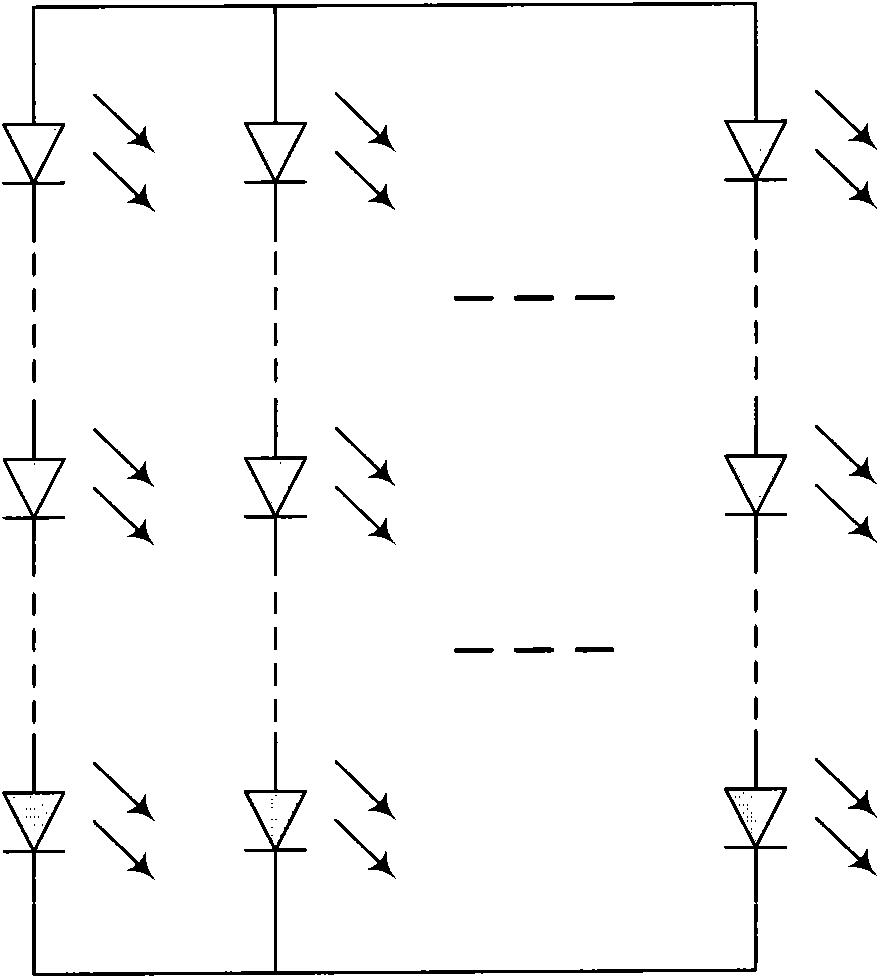

[0035] figure 1 and figure 2 An ultraviolet curing lamp composed of two ultraviolet light emitting diode arrays in the prior art is shown. exist figure 1 and figure 2 Among them, the light-emitting diodes 11 and 21 are different types of high-power ultraviolet light-emitting diodes installed on the base plate respectively, and a plurality of light-emitting diodes 11 and 21 form a light-emitting diode array, thereby obtaining high-power ultraviolet light output. image 3 It is a schematic diagram of a driving mode of light emitting diodes connected in series first and then in parallel in the prior art.

[0036] In order to facilitate understanding of the inventive concept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com