Tire and wheel noise reducing device and system

A tire and wheel technology, applied in the field of sound reduction devices, can solve the problems of inability to reduce low-frequency energy noise, hindering tire inflation, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Exemplary embodiments are described below with reference to FIGS. 1-13 , wherein like reference numerals indicate similar elements.

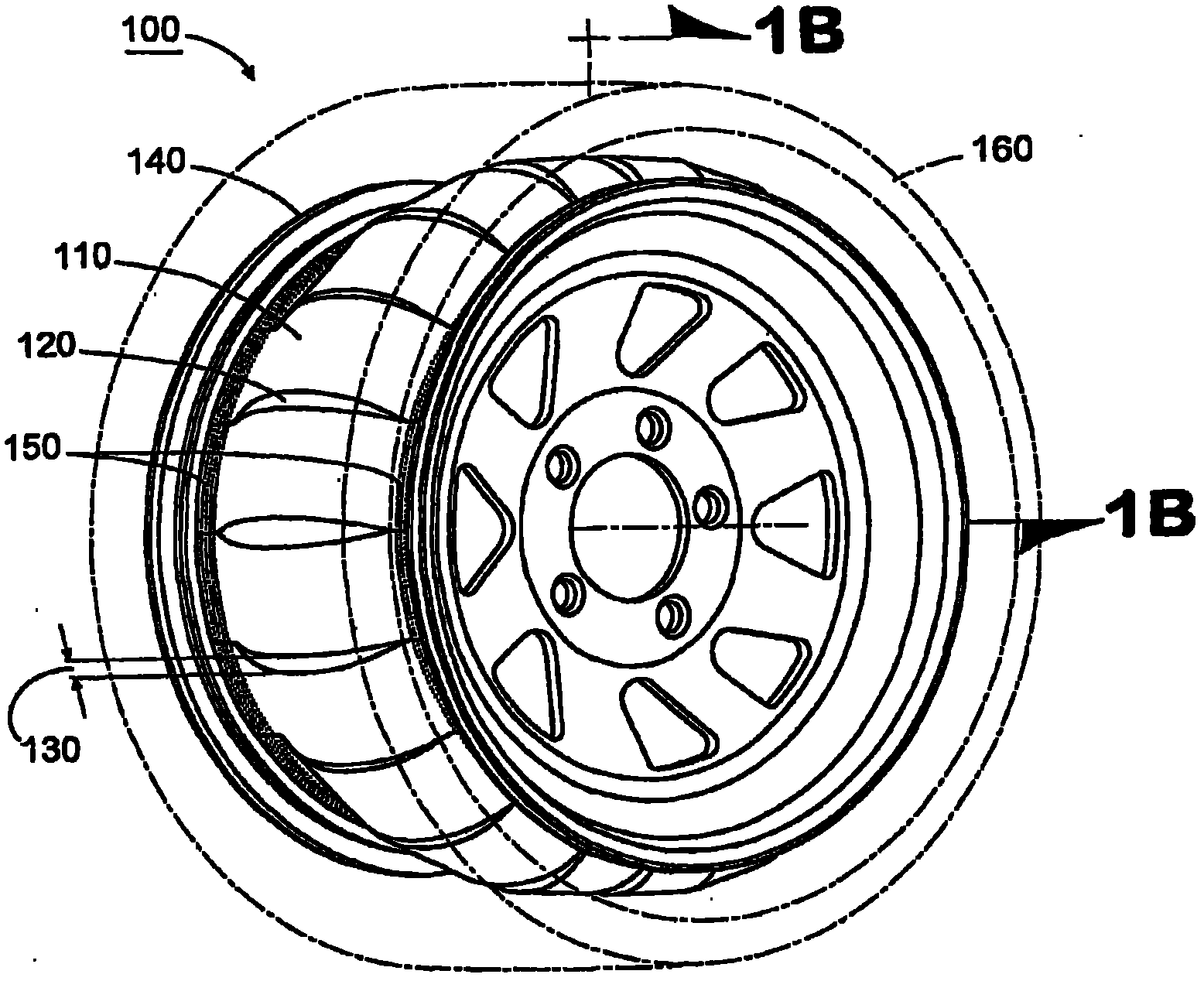

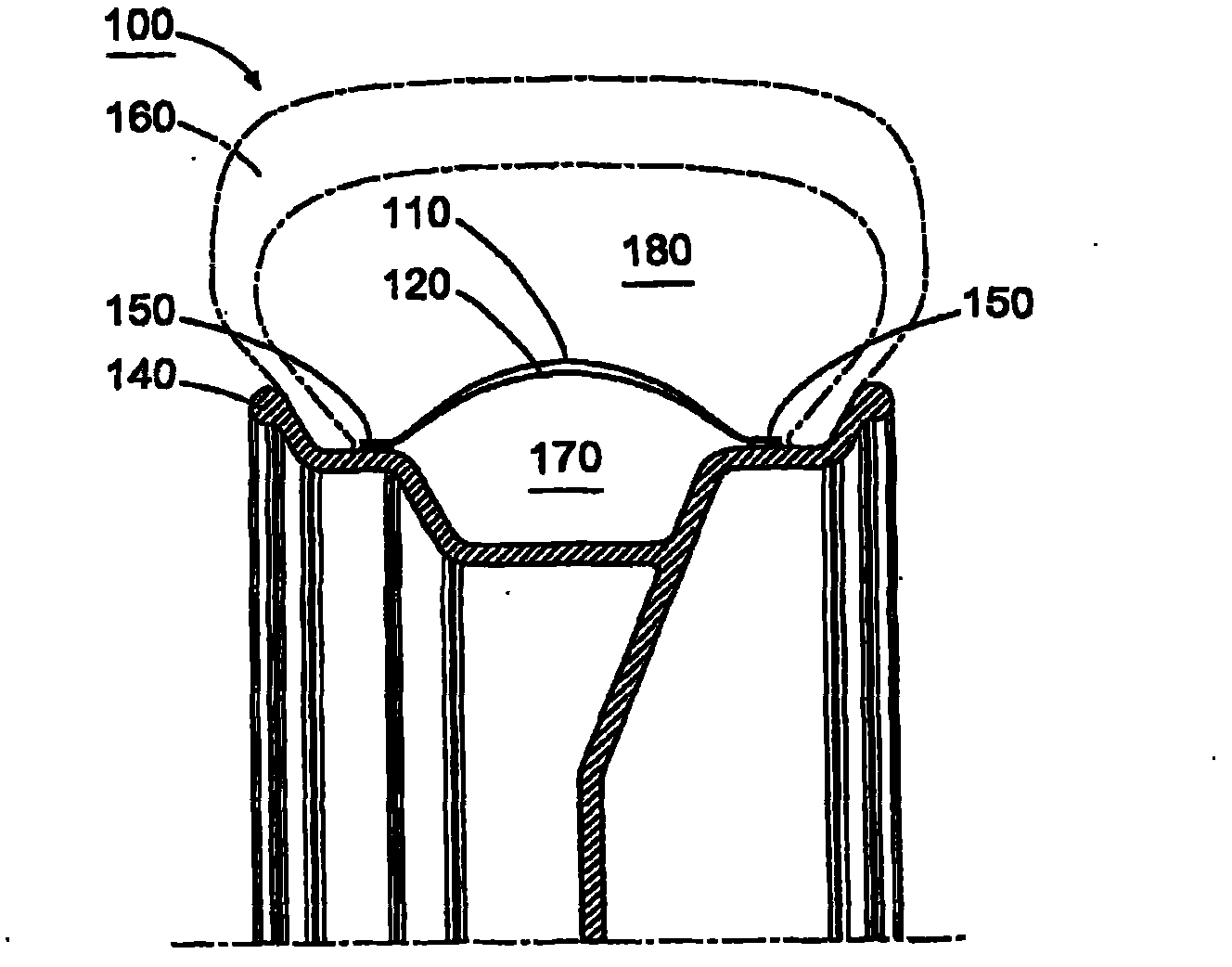

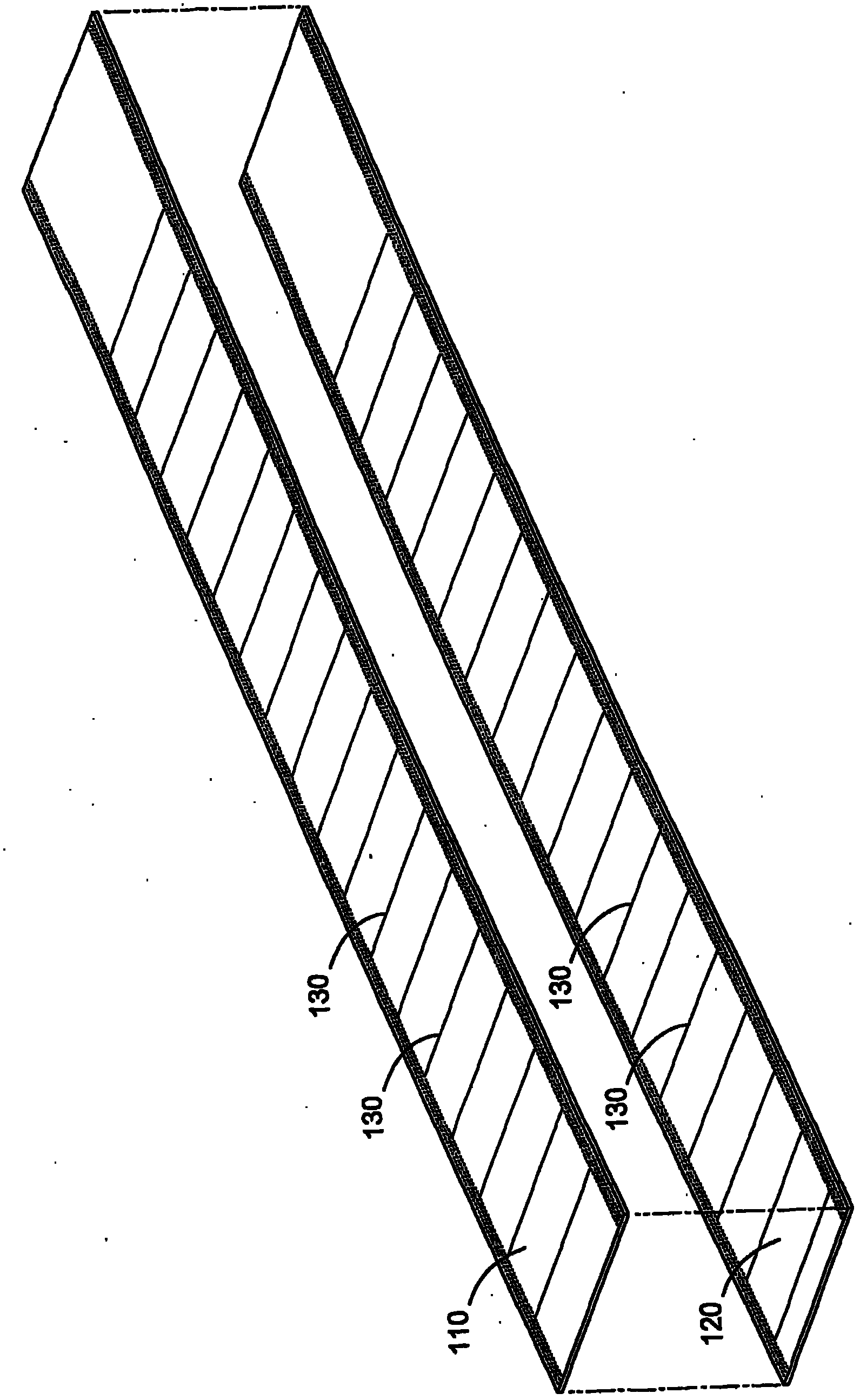

[0043] Figure 1A is a perspective view showing a tire noise absorbing system 100 including a flow blocking barrier disposed on a wheel 140 for a tire 160 according to an exemplary embodiment. Figure 1B yes Figure 1A A cross-sectional view of the exemplary system 100 shown in . Such as Figure 1A and 1B As shown in , the system 100 includes a plurality of overlapping material layers 110, 120 that form a sound-related flow-resistant barrier. Layer 110 includes an outer layer with respect to wheel 140 and layer 120 includes an inner layer with respect to wheel 140 . The overlapping layers 110, 120 are joined to the wheel 140 at locations 150 along their edges to form overlapping loops of material. In other words, layers 110 , 120 surround wheel 140 and are bonded to both sides of wheel 140 at location 150 . Location 150 represents any...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com